Leading IT Transformation – Workshop 21 (Fine-Tuning Kanban)

The Appleton Greene Corporate Training Program (CTP) for Leading IT Transformation is provided by Ms. Drabenstadt MBA BBA Certified Learning Provider (CLP). Program Specifications: Monthly cost USD$2,500.00; Monthly Workshops 6 hours; Monthly Support 4 hours; Program Duration 24 months; Program orders subject to ongoing availability.

If you would like to view the Client Information Hub (CIH) for this program, please Click Here

Learning Provider Profile

Ms. Drabenstadt is a Certified Learning Provider (CLP) at Appleton Greene and she has experience in Information Technology, Information Governance, Compliance and Audit. She has achieved an MBA, and BBA. She has industry experience within the following sectors: Technology; Insurance and Financial Services. She has had commercial experience within the following countries: United States of America, Canada, Australia, India, Trinidad, and Jamaica. Her program will initially be available in the following cities: Madison WI; Minneapolis MN; Chicago IL; Atlanta GA and Denver CO. Her personal achievements include: Developed Trusted IT-Business Relationship; Delivered Increased Business Value/Time; Decreased IT Costs; Re-tooled IT Staff; Increased IT Employee Morale. Her service skills incorporate: IT transformation leadership; process improvement; change management; program management and information governance.

MOST Analysis

Mission Statement

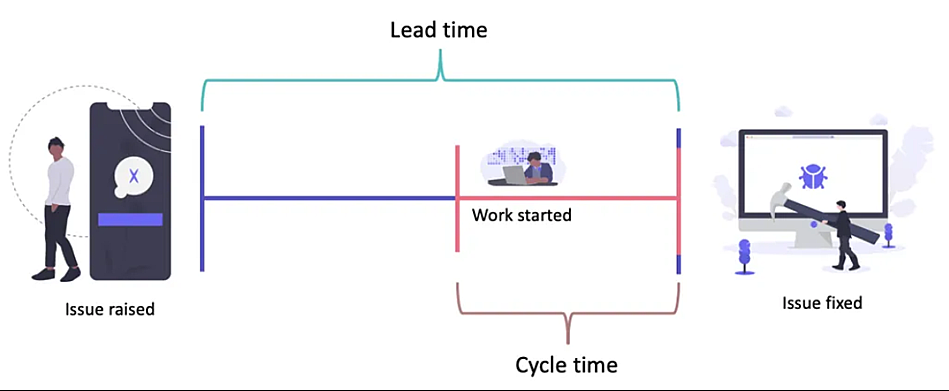

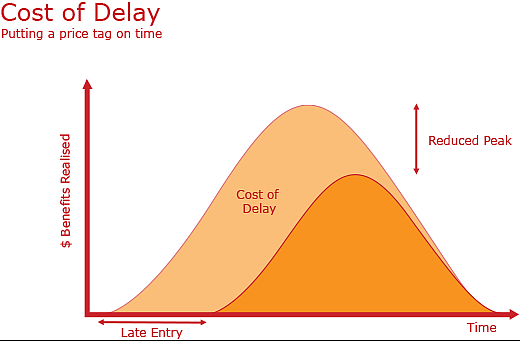

The implementation of Kanban can be made more fruitful by fine-tuning the process and adding ways to monitor and measure the success of the method. The implementation of Kanban principles may seem easy but in practice, there may be many challenges that an organization faces. The Kanban method not only affects the program it is being applied but changes the way the entire organization works. Workflows from one desk to the next only when there is capacity. Products will be procured only when there is a need. These practices, though highly beneficial to the organization overall, may be hard to adopt for all employees. So training and knowledge sharing are important to ensure that all employees are able to recognize the real benefits of using the Kanban system. Once the system is rolling, it is also important to measure its progress and its impact. For this, certain metrics have to be chosen which can reflect how Kanban has improved the process. These metrics could be time-based, productivity-based, and so on. For example, the lead time and cycle time shows the average speed of a team on a task during a given time period. Improvements in the lead time and cycle time are indicative of improvements in the process. Another metric commonly used is Throughput, which gives the number of tasks finished with a given time period. Improvements in Throughput also indicate improvements in workflow. These and other metrics can help to continuously monitor the implementation of Kanban and measure its success.

Objectives

01. Never Pass Defective Products: departmental SWOT analysis; strategy research & development. Time Allocated: 1 Month

02. Take Only What’s Needed: departmental SWOT analysis; strategy research & development. Time Allocated: 1 Month

03. Produce the Exact Quantity Required: departmental SWOT analysis; strategy research & development. Time Allocated: 1 Month

04. Level the Production: departmental SWOT analysis; strategy research & development. Time Allocated: 1 Month

05. Process Optimization – Lead & Cycle Time: departmental SWOT analysis; strategy research & development. Time Allocated: 1 Month

06. Process Optimization – Throughput: departmental SWOT analysis; strategy research & development. Time Allocated: 1 Month

07. Kanban Metrics Charts: departmental SWOT analysis; strategy research & development. 1 Month

Strategies

01. Never Pass Defective Products: Each individual department head to undertake departmental SWOT analysis; strategy research & development.

02. Take Only What’s Needed: Each individual department head to undertake departmental SWOT analysis; strategy research & development.

03. Produce the Exact Quantity Required: Each individual department head to undertake departmental SWOT analysis; strategy research & development.

04. Level the Production: Each individual department head to undertake departmental SWOT analysis; strategy research & development.

05. Process Optimization – Lead & Cycle Time: Each individual department head to undertake departmental SWOT analysis; strategy research & development.

06. Process Optimization – Throughput: Each individual department head to undertake departmental SWOT analysis; strategy research & development.

07. Kanban Metrics Charts: Each individual department head to undertake departmental SWOT analysis; strategy research & development.

Tasks

01. Create a task on your calendar, to be completed within the next month, to analyze Never Pass Defective Products.

02. Create a task on your calendar, to be completed within the next month, to analyze Take Only What’s Needed.

03. Create a task on your calendar, to be completed within the next month, to analyze Produce the Exact Quantity Required.

04. Create a task on your calendar, to be completed within the next month, to analyze Level the Production.

05. Create a task on your calendar, to be completed within the next month, to analyze Process Optimization – Lead & Cycle Time.

06. Create a task on your calendar, to be completed within the next month, to analyze Process Optimization – Throughput.

07. Create a task on your calendar, to be completed within the next month, to analyze Kanban Metrics Charts.

Introduction

An overview of the history of the Kanban software development methodology and the significance of the fine-tuning stage

Let’s look at the following exurb. It is from David J. Anderson’s blog post titled “A History of Kanban for Creative Knowledge Work.”

October 2004

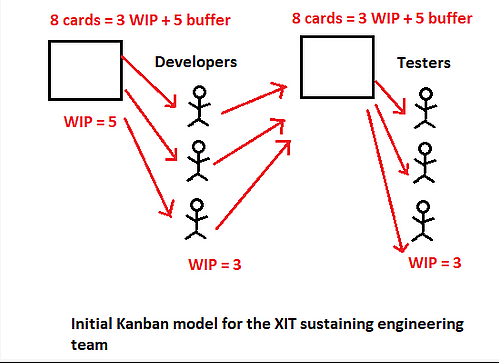

Dragos Dumitriu seeks assistance from David J. Anderson, manager of Microsoft’s XIT sustaining engineering. Dragos’ team has a pull mechanism that David designed and helped introduce. Dragos then persuaded his four product managers and his four superiors to support the concept.

The system was implemented by Microsoft Product Studio without the use of a physical board, and the engineering team was located in Hyderabad, India.

The method used operated under the assumption that the test was the bottleneck and was modeled after the Theory of Constraints Drum-Buffer-Rope.

2005

Donald Reinersten followed David to his house in Seattle after seeing him present his flow and FDD material in the winter of 2005 at a conference in Chicago. On the Microsoft campus, David was visited by Donald, who persuaded him to explore Kanban methods.

David makes the choice to go back and redo the XIT implementation as a Kanban system. He finds that not much would alter; possibly the WIP limitations would vary significantly.

David starts referring to the XIT implementation as a virtual Kanban system and presents it the next year in Chicago since he finds Kanban systems easier to describe to others.

The XIT sustaining engineering research was presented at TOCICO in Barcelona in October 2005, and Microsoft later released it as a white paper.

2006

In the winter of 2006, David gives a presentation at the same Chicago conference where Donald had followed him home the year before on the finished XIT narrative as a virtual kanban system implementation.

It is the first time that Kanban systems applied to knowledge work have been shown in public. Only Dragos and David were previously involved.

The Microsoft IT solution was read and used by certain people in the summer of 2006. Notably, Eric Landes from Robert Bosch copied it almost verbatim for use by a team responsible for maintaining an intranet website.

David moves jobs in September of 2006 to work for Corbis as Senior Director of Software Engineering.

He acknowledges that the software maintenance procedure is seriously flawed and collaborates with Rick Garber, the team’s boss, to create a Kanban system.

It was intended to take the place of the current project-centric strategy for small application changes.

Drew McLean, VP of Corbis, recommends the expedite capability—which brought the first alternative class of service to a Kanban system for knowledge work—when engaging with stakeholders.

In November 2006, Diana Kolomiyets, the project manager, and Darren Davis, the development manager for maintenance, took charge of the Kanban implementation.

Diana oversees replenishment meetings every week, plans and coordinates releases every two weeks, while Darren is in charge of standup meetings.

Corbis conducts an operations evaluation of its IT in December 2006. Darren Davis explains the evaluation’s findings after implementing the first Kanban system.

2007

In January 2007, Darren Davis made the claim that the seeming high level of variation inflow was caused by the stasis of improvements following a number of successful releases from the maintenance process. Nobody is sure of what to do next.

He proposes using a card wall that has been set up on a whiteboard across the hall from his cubicle to visualize the procedure. One of his team members came up with this concept. A sign is placed on the wall.

Winter of 2007: Additional improvements are being made to the wall, and space has been set aside for internal needs. For green tickets, there is a WIP limit of two.

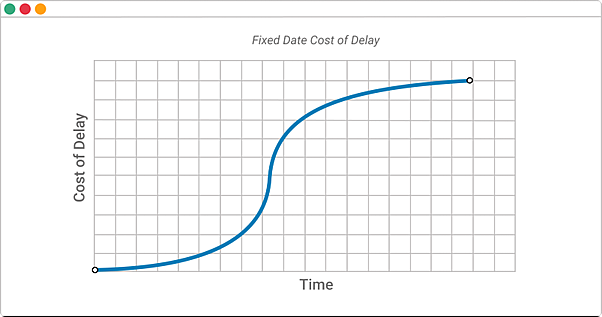

David observed a pattern of urgent work with predetermined deadlines. As a type of service, he advises providing a “fixed date” notion.

At the end of this season, what is now known as the Kanban technique emerges, with its six practices and hazards displayed and addressed via capacity allocation and classes of service.

At Corbis, Corey Ladas is employed as a process coach for Kanban after leaving Microsoft.

The new CEO of Corbis inquires in April 2007 as to why the new maintenance procedure isn’t being applied to all aspects of IT if it is performing so effectively. David adopts the idea and introduces Kanban to the entire project portfolio.

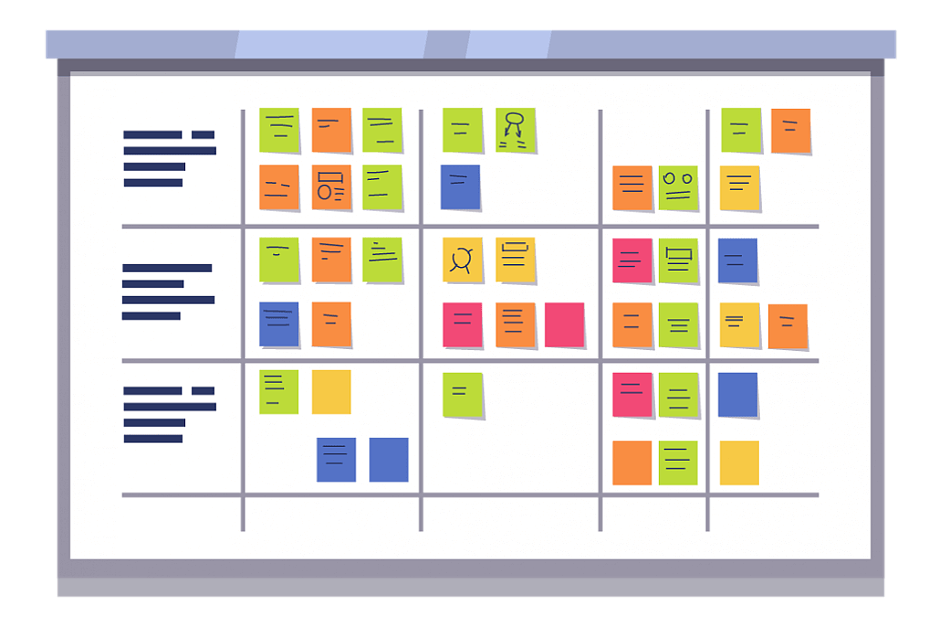

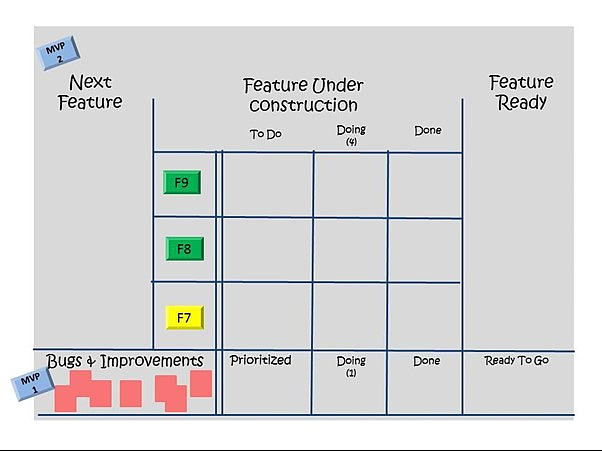

Under Corey’s direction, the digital asset management (DAM) project implemented Scrum and Kanban. This two-tiered Kanban board with swim lanes is the first of its kind.

Dan is hired as the development manager for the ERP project in May of 2007. Dan has never used Kanban, yet he and Corey created the project’s methodology.

They transfer the DAM project staff to the ERP project while carrying the two-tiered, swim lane Kanban board with them.

Rick Garber and David attend Donald’s Lean New Product Development conference in Chicago in June 2007. Only 55 people were present in the crowd.

It is the first time the now-famous Kanban approach has been shown, and it includes features like operations review, lead time histogram metrics, classes of service, and metrics for those variables.

David delivers the same speech from June at the conference inside a conference at the Agile Conference in Washington, D.C., in August 2007.

The following day, Karl Scotland, Joe Arnold, and Aaron Sanders, representatives from Yahoo!, are present and speak with David.

They express their admiration for David’s evolutionary approach to change and alternate strategy for achieving agility through the use of virtual Kanban systems.

They clarify that they have attempted to introduce Scrum at Yahoo! but have encountered significant opposition. With the organizations who are opposing, they want to attempt Kanban.

They created a Yahoo! discussion forum where they could share their stories. At Yahoo!, the kanbandev group was created today and is still in use.

2008

At the Agile 2008 conference in August of 2008, Corey Ladas offers more thorough implementation examples. The presentation’s second half focuses on applying Kanban in Scrum-based teams and projects. It serves as the basis for what would be referred to as scrumban.

2009

Published in January 2009, Corey Ladas’ book Scrumban describes how to use Kanban to advance Scrum.

The inaugural Lean Kanban conference, an initiative put up by the kanbandev group at Yahoo!, takes place in Miami in May of 2009.

Jim Benson and David had a meeting to discuss the conference in Miami.

They talk about how using Kanban for personal purposes differs from using it for business workflows (currently referred to as the Service Delivery Kanban).

Everywhere, even the Modus Cooperandi office, there had been a case of personal usage emerging.

Jim Benson releases Personal Kanban in July 2009 as a collection of 12 blog postings.

Jim Benson introduces personalkanban.com in October 2009.

2010

It has been published, Kanban- Successful Evolutionary Change for your Technology Business.

It has evolved into the greatest and most comprehensive guide for putting Kanban systems into practice in companies that employ creative and knowledge workers. Well over 40,000 copies have been sold.

Kanban at Spotify

This is likely one of the earliest and most well-known instances of how Kanban Fine-tuning functions in IT, excluding the Microsoft scenario that was previously stated. Scalability was the biggest issue, according to Mattias Jansson, an operations engineer at Spotify. He was implying that the operations staff was unable to develop along with the demands of the business.

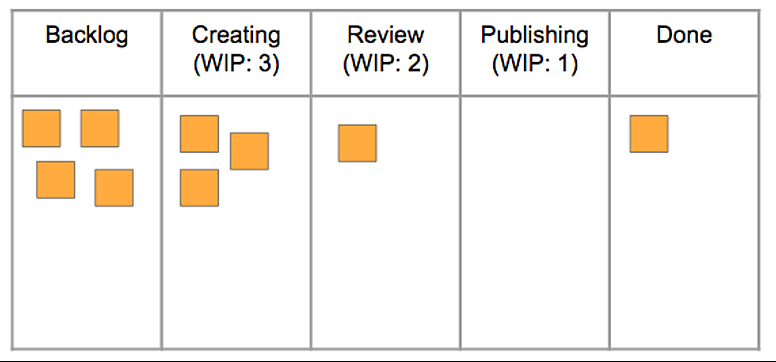

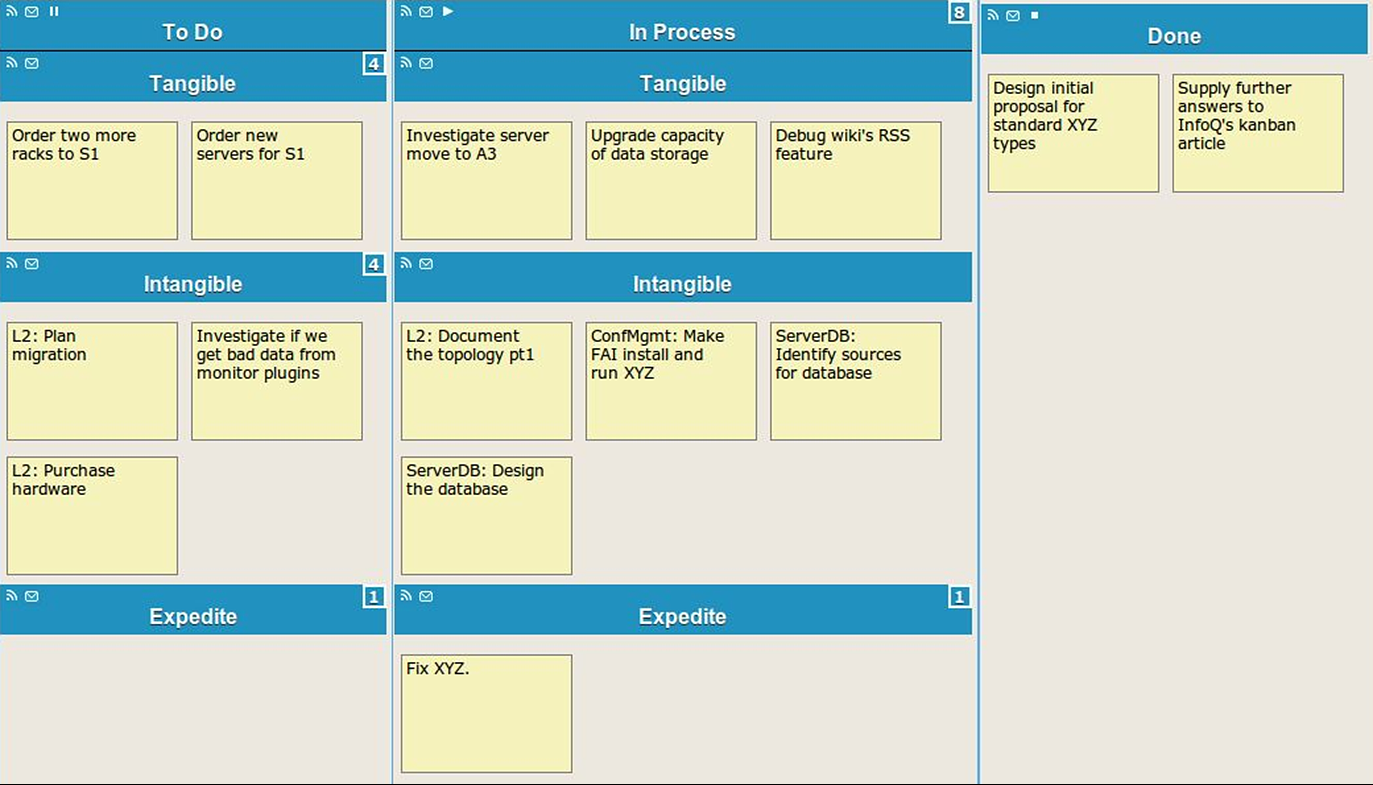

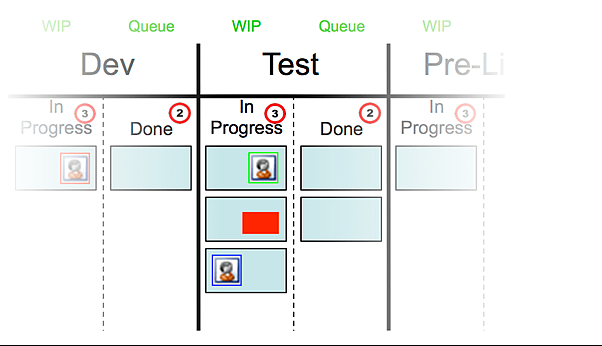

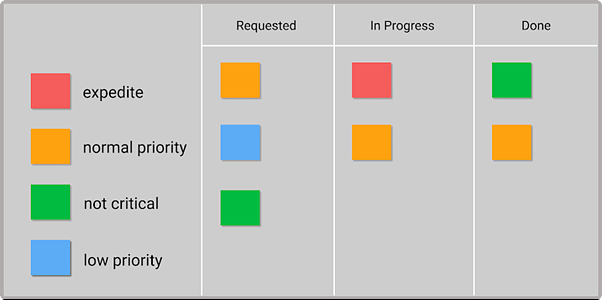

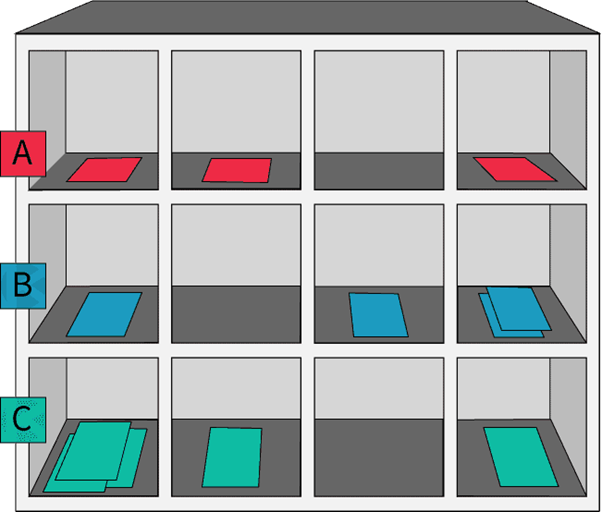

They made the decision to use Kanban as their workflow management solution as a result. The group decided to start out easy. The graphic below shows how easily they set up a Kanban IT operations board:

• 3 columns (to do, doing and done);

• 3 horizontal lanes. Two for the main types of service: standard type and intangible stories and an expedite swimlane;

• They set a low WIP limit on the To-Do stage to ensure that the internal, intangible tasks are actually done;

• They also set a WIP limit on the Doing column equal to the number of ops team members minus one.

Image credit: infoq.com/articles/kanban-operations-spotify

After all, it appeared that Kanban helped the Spotify Ops team become more efficient. As Mattias said in an interview “We’ve noticed that our lead times are shorter, we get more internal tasks done, and the departments we interface with are happier.”

Fine-Tuning Kanban

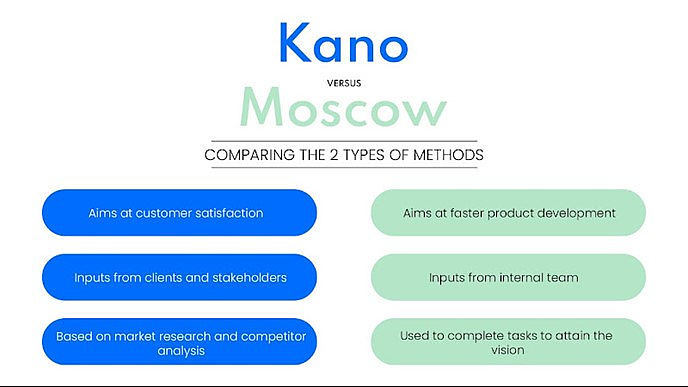

To make sure your Kanban process is effective for your team, it’s crucial to fine-tune its effectiveness. You may evaluate the effectiveness of the Kanban system using various key measures. Understanding where there are bottlenecks and how to avoid them in the future depends on keeping track of these metrics, especially for your Kanban retrospective sessions. These metrics range from burndown charts to cumulative flow charts.

Kanban Metrics: What to Measure and Why

In this workshop, we’ll go through the precise Kanban metrics & analytics you should be utilizing to keep an eye on your team’s productivity, the effectiveness of your processes, and delivery times, as well as the warning signs of danger to look out for. In the prior workshop, we only touched on these metrics and analytics in passing. Today, however, we will go into further detail and present concrete examples to deepen our explanations.

Good and Bad Metrics: What Does It Mean?

You should be able to distinguish between excellent and bad metrics in order to avoid being duped by the latter. Metrics are excellent if they contribute to system improvement, to put it simply. They are bad if they reward or penalize specific people.

Metrics are Good if they:

• Are actionable and improve the decision-making process

• Lead to better results

• Portray the state of reality

• Improve behavior

Bad metrics:

• Are focused on the past

• Often lead to bad results

• Are used as targets

The expression “what gets measured gets managed” may be familiar to you. The Kanban Method’s fundamental component for tracking projects and gradually improving process efficiency is tracking progress and measuring performance.

Let’s take a quick look at the key Kanban metrics and how to use them to increase productivity.

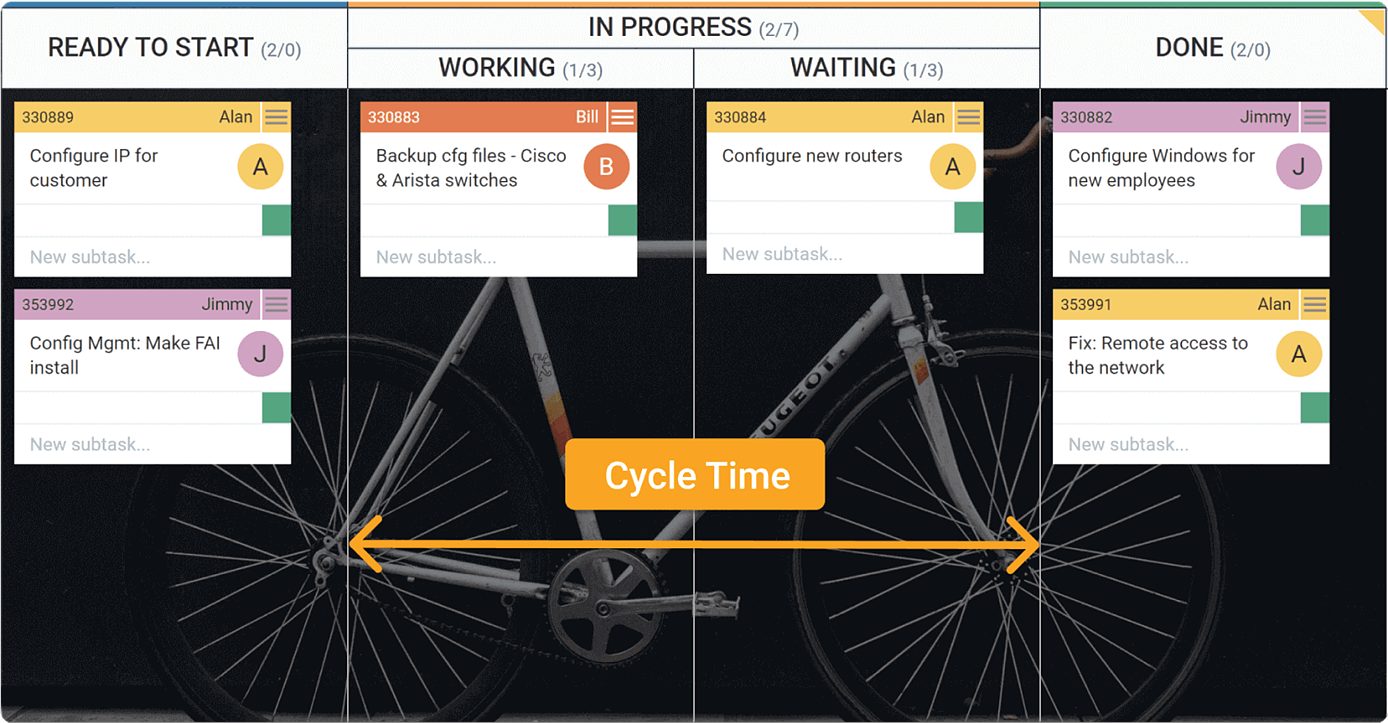

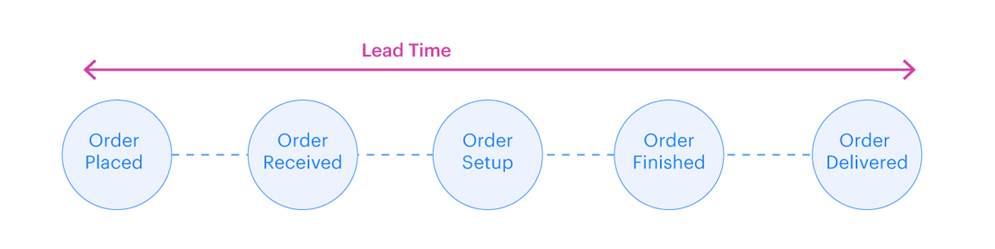

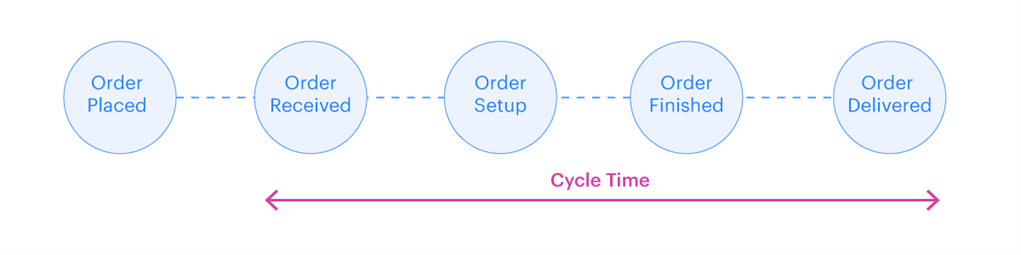

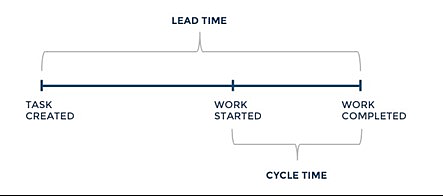

Cycle Times

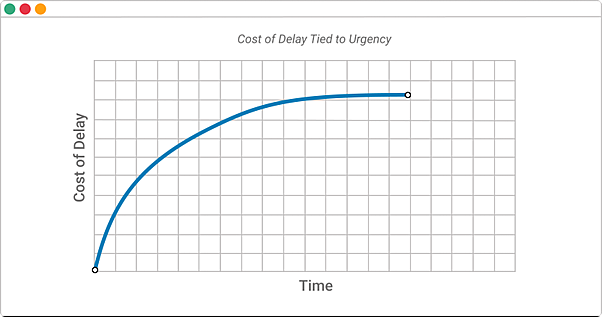

Cycle time, a crucial Kanban indicator, counts the number of steps a task takes to complete. In contrast to lead time, cycle time is only measured from the moment your team begins working on the task.

The metric that accurately gauges how long it takes your team to complete a task is called cycle time. Low cycle times demonstrate effective teamwork, while large cycle times point to a process bottleneck. Reducing cycle times also reduces lead times, which increases customer satisfaction.

Source: Getnave.com

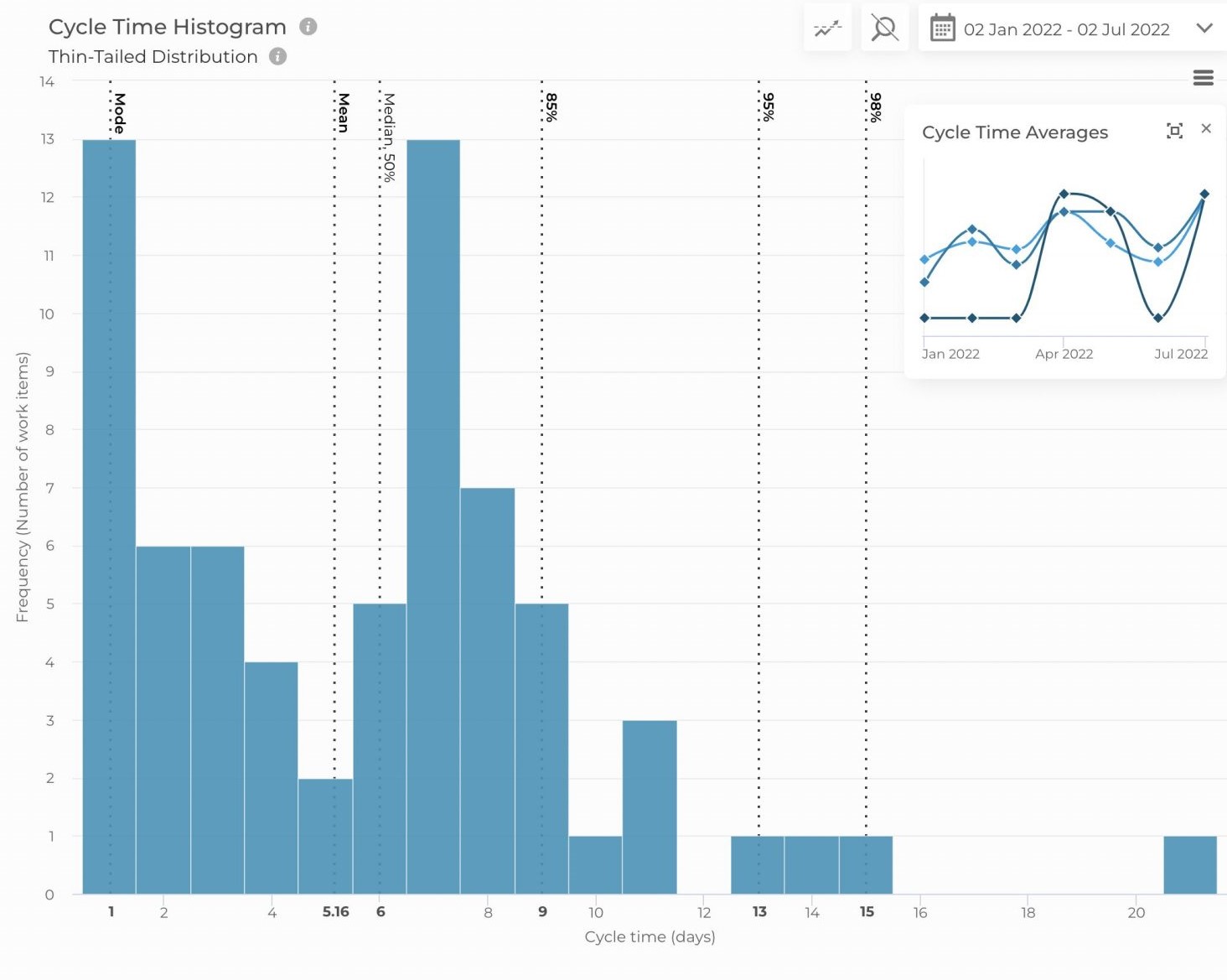

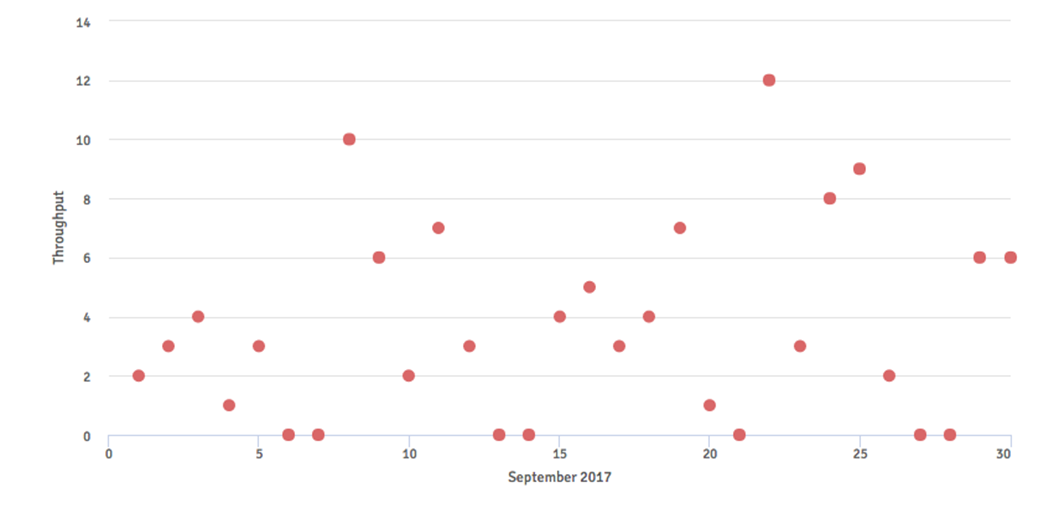

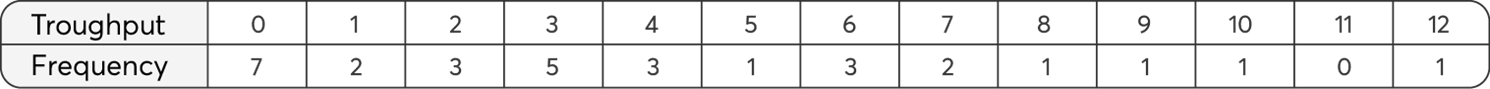

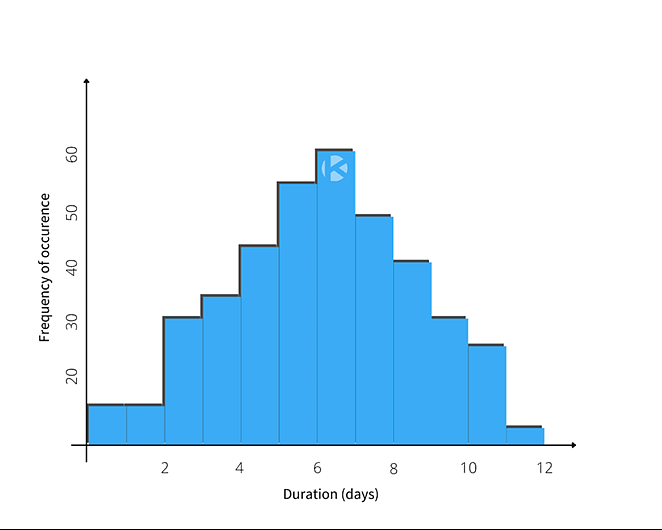

A cycle time histogram can be used to chart your cycle times over time and to forecast when your work will be delivered in the future. The percentile lines in the figure above show that once your team begins working on a task, there is a 50% probability that it will be finished in fewer than 6 days and a 95% chance that it will be finished in less than 13 days.

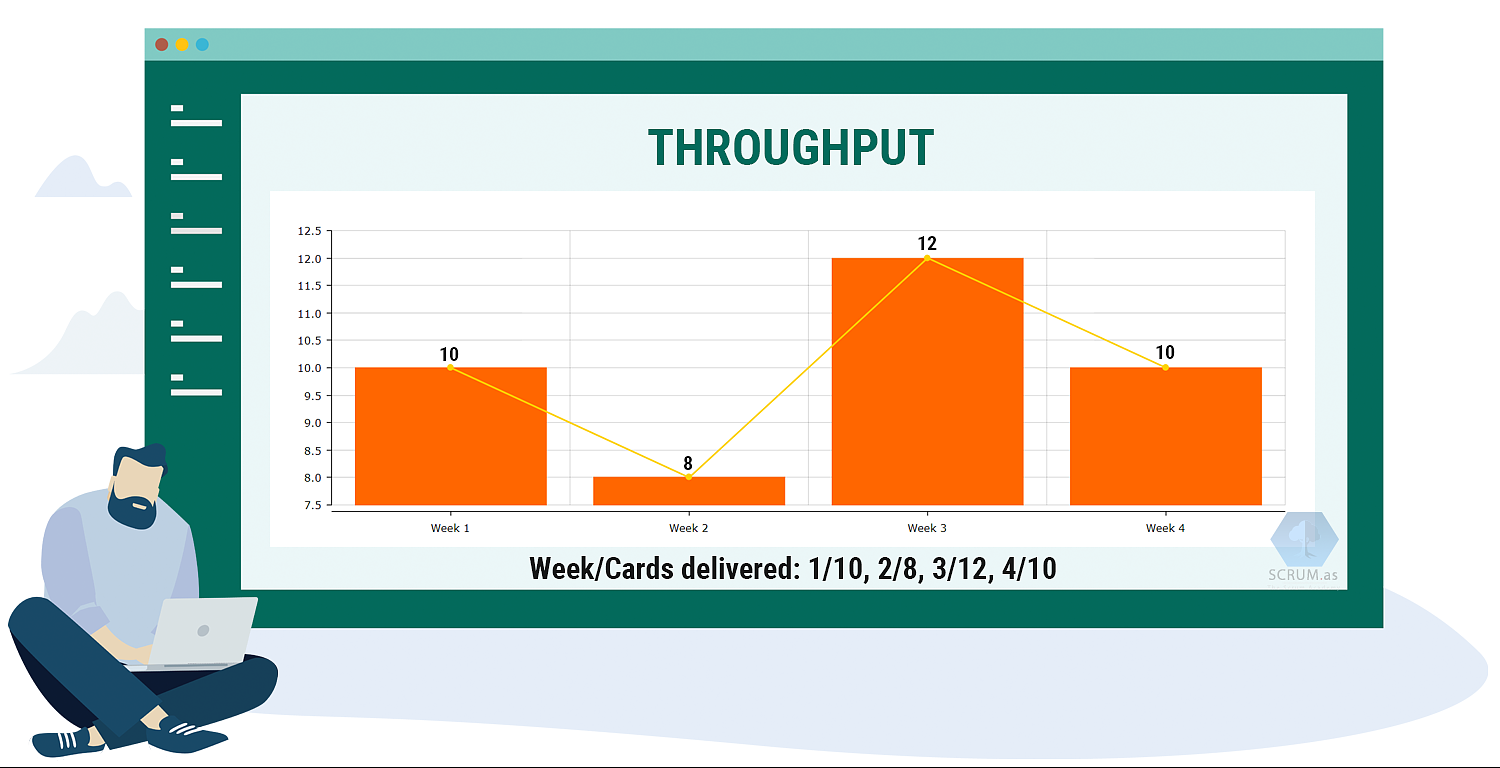

Throughput

The throughput statistic in Kanban indicates the entire quantity of work delivered in a given amount of time, whereas cycle time monitors how long it takes a single job to complete the process. Nothing that is still in process is counted while measuring throughput; only completed work items are counted.

Throughput is an important Kanban metric since it can be used to gauge your ability to produce results. Consider a Kanban team with an average throughput of 5 tasks per week during the previous 5 weeks: 3, 7, 4, 5, and 6. We can estimate that this team can do 5 tasks per week on average without knowing anything about the tasks themselves.

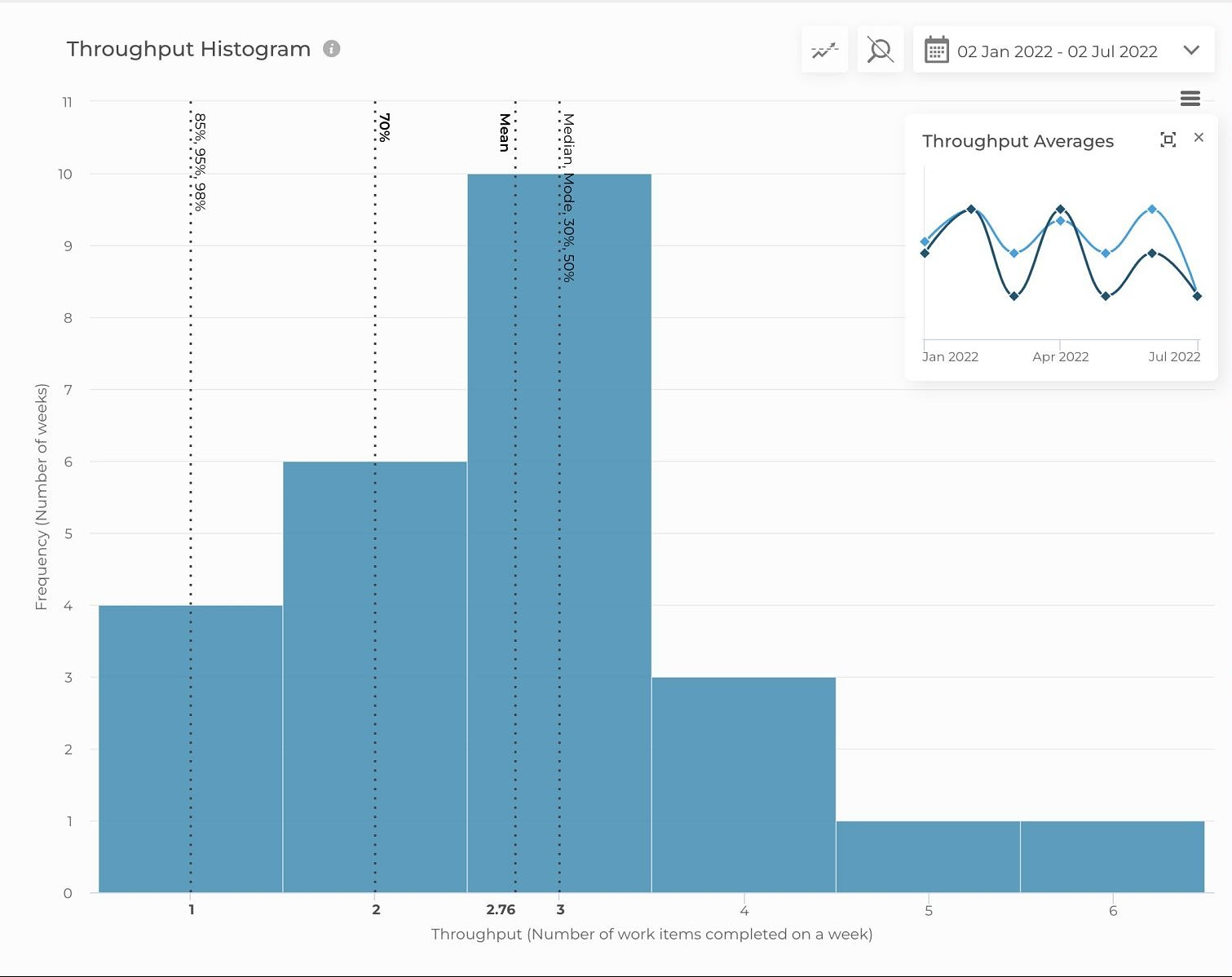

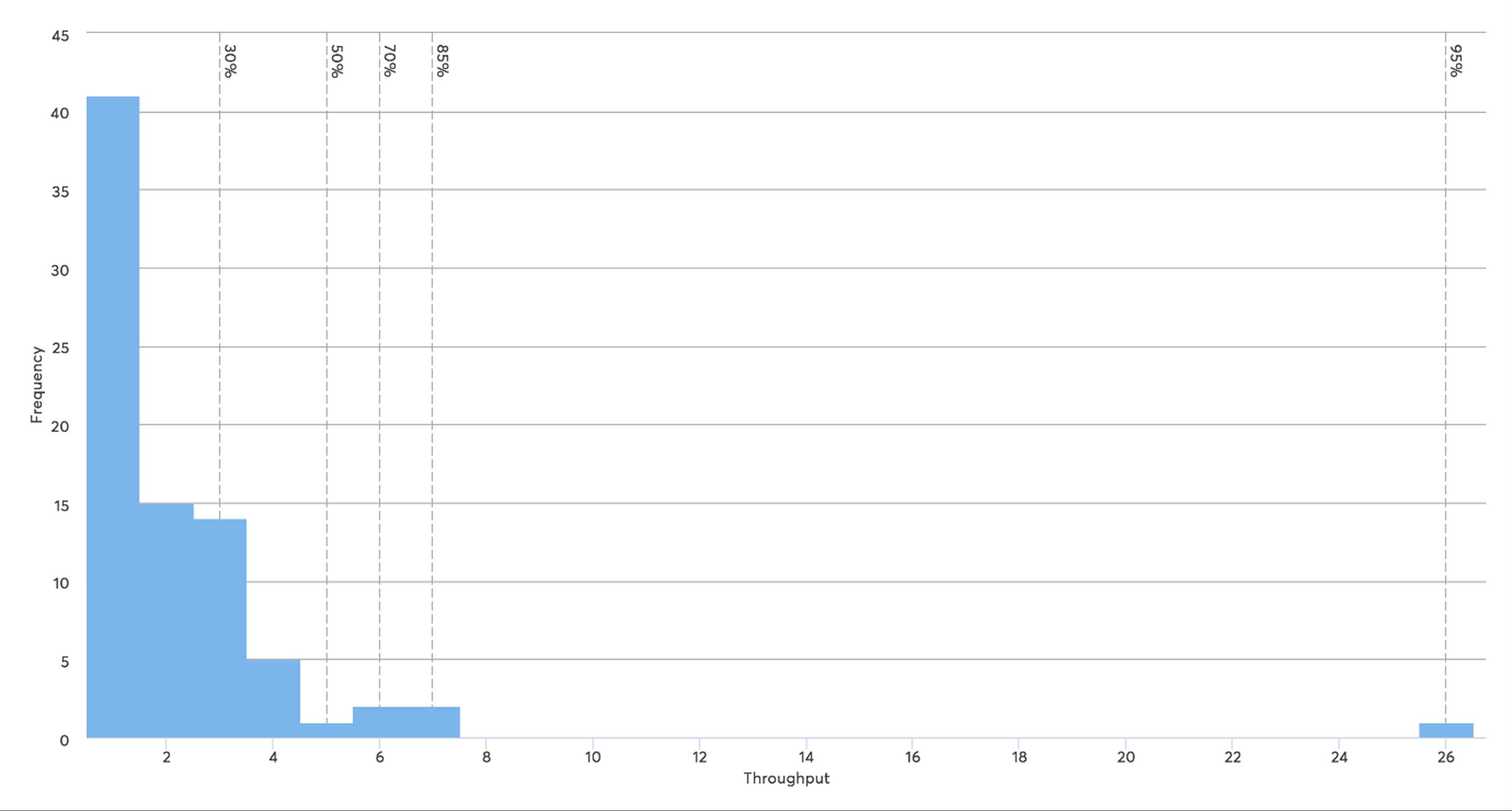

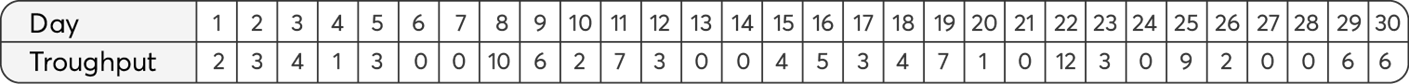

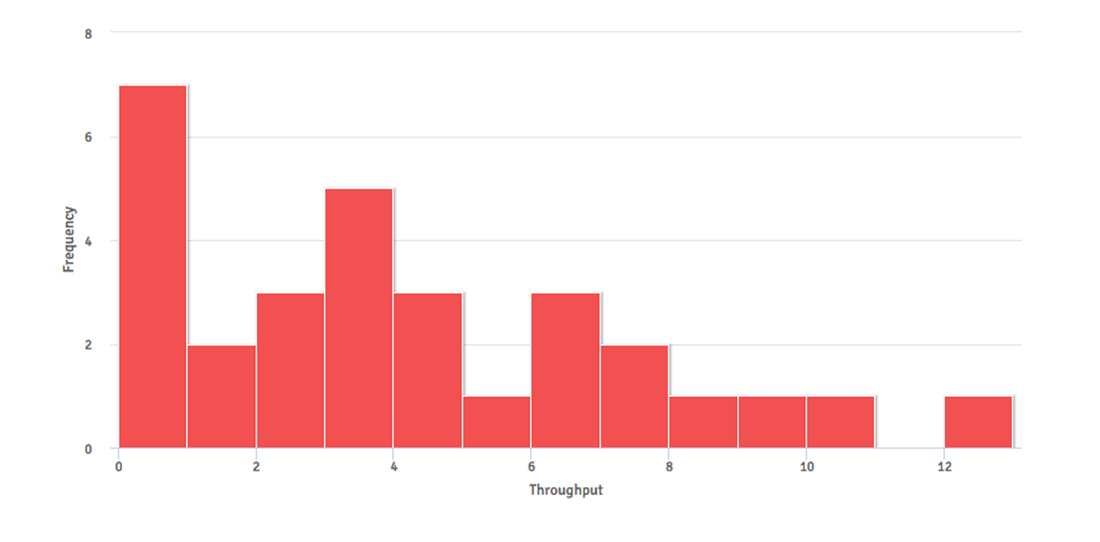

The throughput histogram is used to measure throughput, which is used to track your team’s performance over time. This charts the frequency with which your team reaches a particular throughput over time. According to the graph below, this team has produced 3 items on average every week over the previous 6 months.

Source: Getnave.com

You can observe changes in your team’s performance firsthand by monitoring your throughput over time. A falling throughput suggests that something is negatively hurting your team’s capacity to produce and requires further attention. Ideally, throughput should remain the same or rise.

Work In Progress

Limiting Work In Progress (WIP), as was addressed in the prior workshop, is a crucial aspect of the Kanban Method for increasing team productivity. Consider this: Do you complete work more quickly when you divide your attention between several projects or when you concentrate on only one?

The ideal WIP limit for your team will vary depending on a number of variables, including the size of your team. However, a good starting point is to put the limit at around the same number as your team size so that everyone can concentrate on one work at a time.

Team Performance

Cycle times (how quickly work is completed) and throughput (how much work is delivered) are the two Kanban indicators that best reflect the performance of your team. To make sure you are giving your customers results, keep an eye on these metrics!

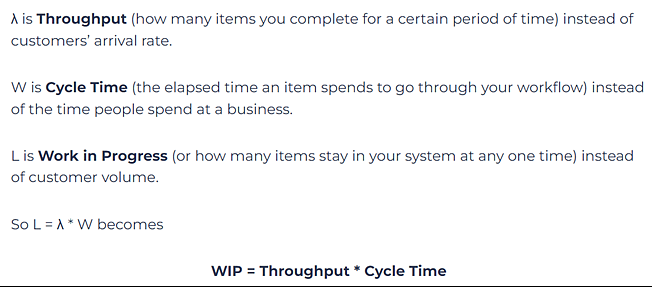

Little’s Law relates cycle time, throughput, and work in progress (WIP). Any system that satisfies the requirements of Little’s Law can use this formula.

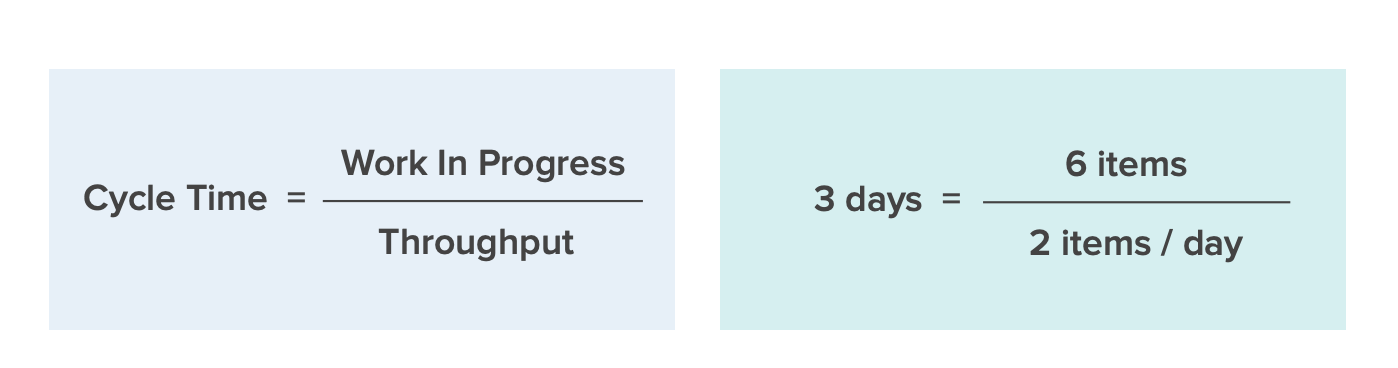

Cycle Time = WIP/Throughput

The link between the three fundamental flow indicators is demonstrated by Little’s Law, which states that altering one will have an impact on the other two. For instance, WIP must reduce for a reduction in cycle time.

High throughput and quick cycle times are indicators of a successful team, but consistency should also be observed. You can examine the average value of your Kanban metrics as well as how this data is spread over time via the cycle time and throughput histograms. Your future forecasts are inherently more accurate when your values are distributed over a smaller range.

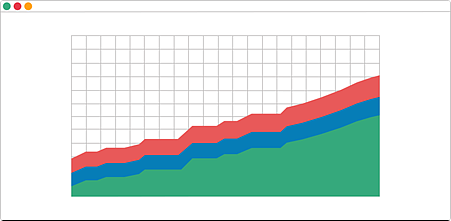

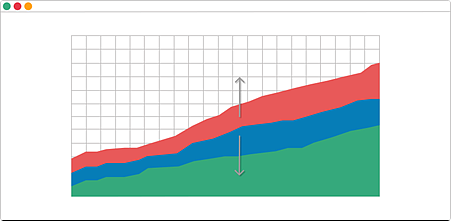

Cumulative Flow Diagram

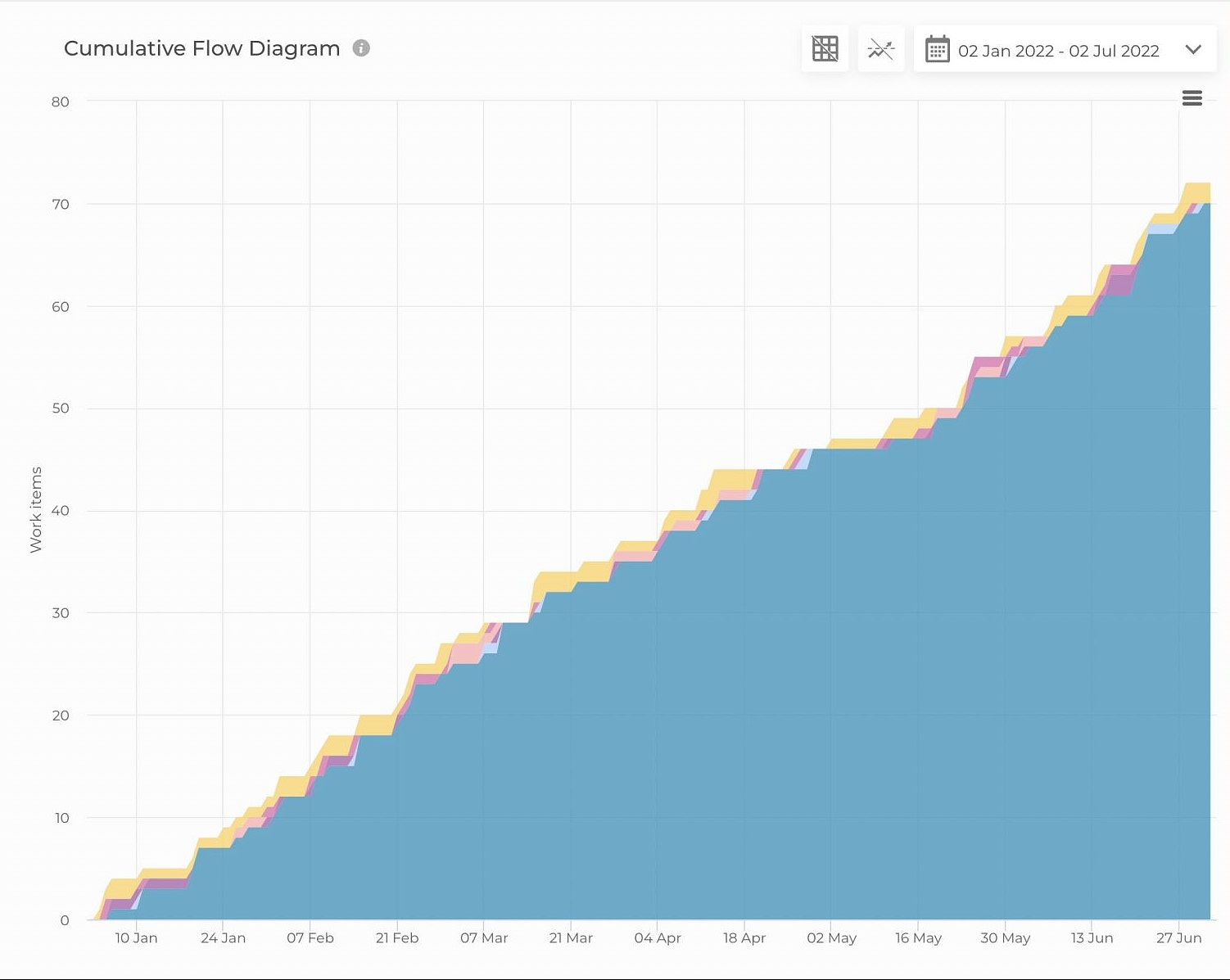

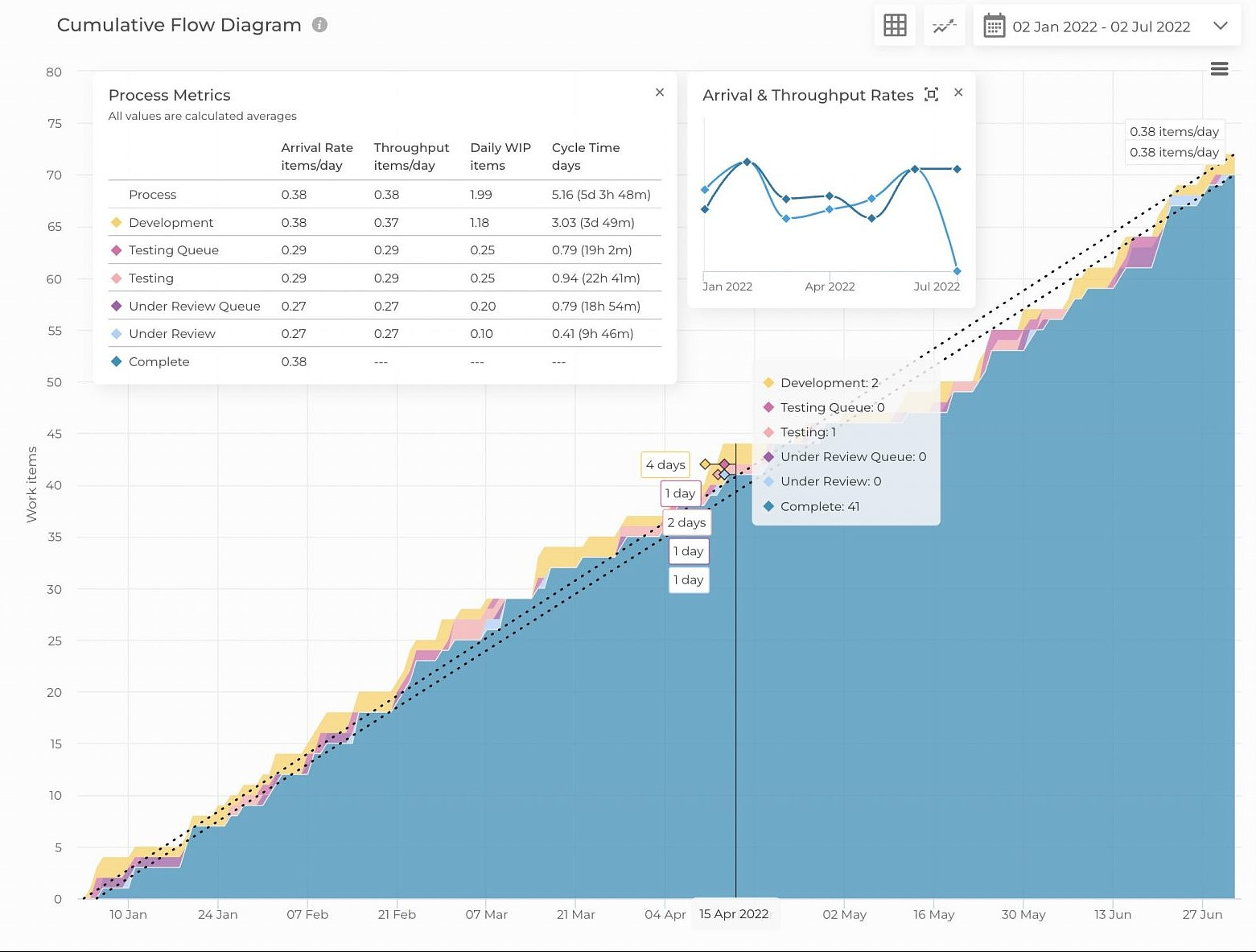

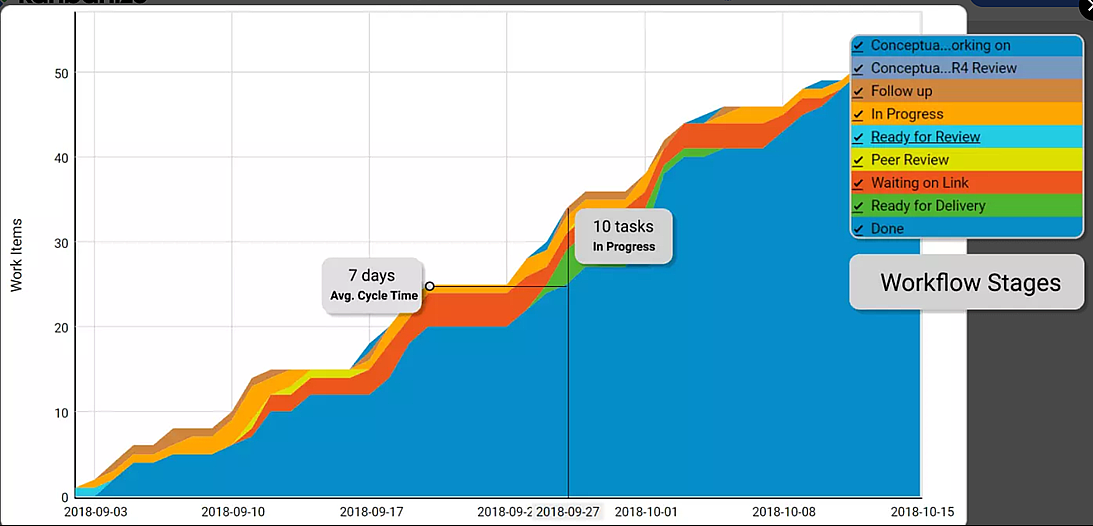

The Kanban Method focuses mostly on gradual evolutionary advancements. When used over prolonged periods of time, it is most effective. Cycle time and throughput tracking have already been covered, but the cumulative flow diagram is the true star for looking at process efficiency over a longer period of time.

Source: Getnave.com

The distribution of jobs throughout each process state is depicted in the cumulative flow diagram as they build up over time. The number of tasks present in each process state at any given time is indicated by the color of the corresponding band. Although it is possible to determine the approximate average cycle time directly from the diagram, the main advantage of the CFD is how quickly you can obtain a visual evaluation of the stability of your process.

The way the gradients of the bands alter over time can be used to quickly identify changes in your team’s performance. Your team is producing work more quickly if the gradient for the “Done” band increases. Contrarily, a steep rise in the gradient of the “In Progress” band denotes the onset of a bottleneck.

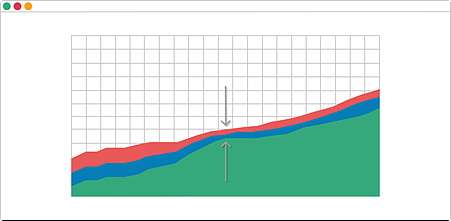

Bottlenecks

The bottleneck, or growing amount of work that is not being finished, is the strongest warning sign that your performance is about to suffer. The bottleneck indicates that your team lacks the resources necessary to complete the workload given to them in a timely manner.

You may identify bottlenecks as they develop using Kanban measurements. Symptoms to look out for include lengthening cycle times, declining throughput, and a rapid increase in gradient in your cumulative flow diagram.

Source: Getnave.com

When you start to notice bottleneck symptoms, it’s important to look closely at the possible causes. Is there an external demand that could be keeping things from moving forward? Has your work-in-progress cap climbed without your knowledge? If your team’s roles have changed, should duties be distributed differently? You should be able to remove bottlenecks before they become an issue by acting swiftly.

The Little-Known Facts about Little’s Law: How to Fast Track Your Way to More Predictable Delivery Systems

Stable delivery methods can help to attain long-term predictability. The phenomenon is eventually defined by Little’s Law. Let’s examine some little-known facts about the law to highlight the real benefits it offers to our business procedures.

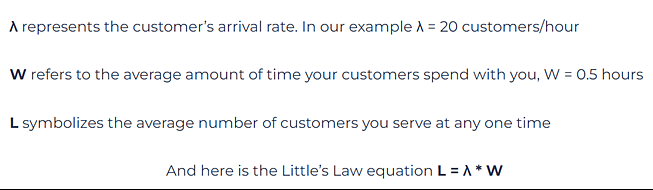

What is the Little’s Law Equation?

Imagine that you manage a stylish and hip taco truck. Your organic, grass-fed shitake mushroom and carne asada burritos are well-known. Customers adore you because your freshly prepared tortilla chips paired with zesty salsa verde are the flavor of the season.

Let’s say that every hour, 20 individuals visit your taco truck. They stay for a half-hour, eating and conversing with one another. How many clients would be waiting outside your food truck at any one time?

Little’s Law states the following:

Based on that formula we can calculate that the average number of customers you handle at once is L = 20 * 0.5 = 10 customers.

So why does it matter?

The Purpose of the Law in Project Management

Let’s look at how business leaders use Little’s Law in the real world to make their workflows more predictable.

You can determine the capacity of your systems using Little’s Law. In order to achieve this, the formula can be written somewhat differently:

You must keep in mind the following three crucial points regarding Little’s Law:

• Little’s Law is an unreliable approach to making delivery commitments

• Little’s Law is an equation of averages

• Little’s Law is about examining what has happened in the past

Let’s look into all three in more detail.

Little’s Law Is an Unreliable Approach to Making Delivery Commitments

Most people would argue that the true value of Little’s Law lies in being able to make predictions in the future. So the question is, does the law serve this purpose?

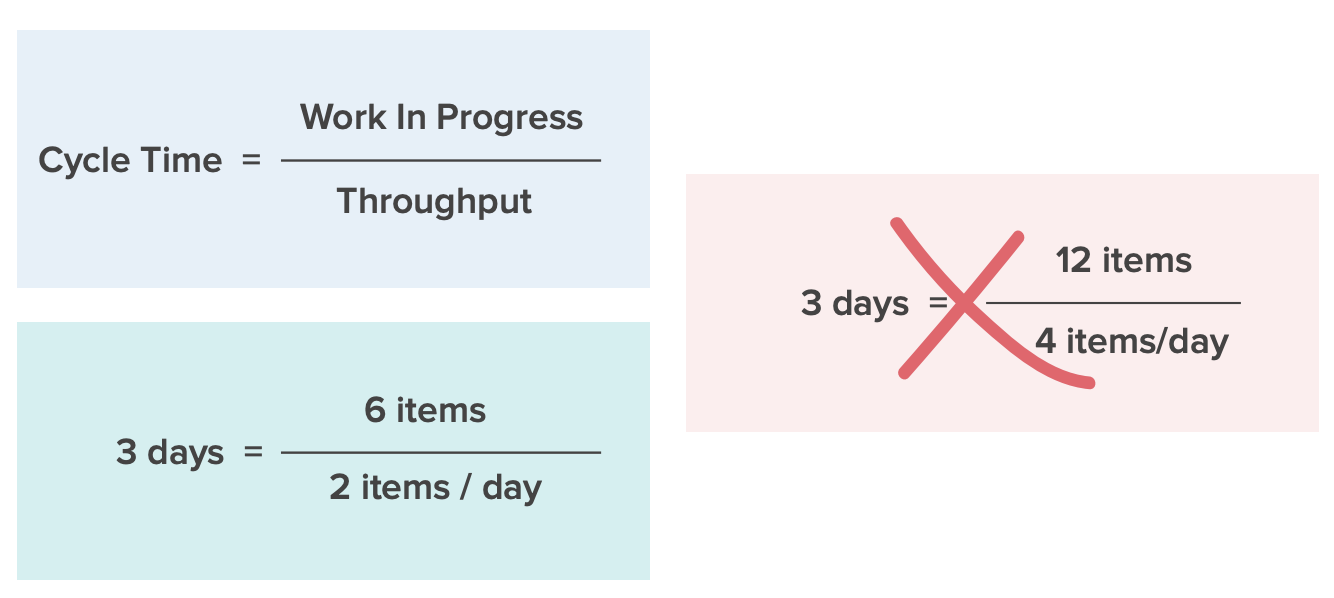

Let’s look into the following example. Let’s say you have an average WIP of 6 items and an average throughput of 2 items per day. This configuration gives your team an average cycle time of 3 days.

What happens if we raise our WIP? The fact is, you cannot say that if you increase the average WIP to 12 tasks and keep the average cycle time constant of 3 days, then your average throughput will increase to 4 tasks/day.

That forecast will not be made using Little’s Law. The only thing Little’s Law will tell you is that an increase in average WIP will cause an alteration to either (or both) of the two important measures, average cycle time and average throughput.

All of the underlying assumptions for the Little’s Law equation must be true for the time period under study. I’ll talk more about that shortly.

Little’s Law Is an Equation of Averages

In addition, Little’s Law is a relationship of averages since each element in the relationship is an average. An average will be produced by this calculation. Therefore, using this method we are unable to make any probabilistic predictions.

It’s dangerous to rely predictions on averages. Average-based forecasts would only make sense if you were familiar with the nature of the data’s underlying distribution. If you don’t, there’s no way to know if your chances of success are exactly 50%, significantly more than 50%, or significantly less than 50%.

Would you agree to a delivery date with a 20% likelihood of fulfillment? We categorically advise against doing this.

The Law Is All about Examining What Has Happened in the Past

Little’s Law is about examining the predictability of your system in the past. It was created primarily to assess the robustness of a delivery workflow using data that had already been acquired.

The average throughput rate and average arrival rate will be about equal in a stable system. This indicates that tasks enter the process at the same rate at which they exit it. Furthermore, the Little’s Law equation used to analyze your historical performance data will be quite accurate if you are in charge of your management procedures and you are upholding a predictable workflow.

Check your process measurements against Little’s Law to see if the equation fails. You can examine your work by process states using Little’s Law. The same idea applies in this case. Your system is more stable the more exact the equation. Furthermore, predictable systems are stable systems.

The Little-Known Fact about Little’s Law Everyone Should Be Aware Of

The equation itself is actually not that significant. Little’s Law’s true worth comes from its capacity to deepen our comprehension of the relationships among the three fundamental flow measurements.

The most typical trend is a steady rise in WIP. According to Little’s Law, as your WIP increases, so do your cycle times. In a world where Cycle Time is always increasing, how could you be predictable? You really can’t.

Each and every one of you should be aware of a little-known fact concerning Little’s Law. It almost doesn’t matter if you can use the Little’s Law equation or not. The underlying presumptions of the law are what give it its power. It offers guidance on how to adopt a set of process policies to promote uniformity and increase workflow predictability.

Executive Summary

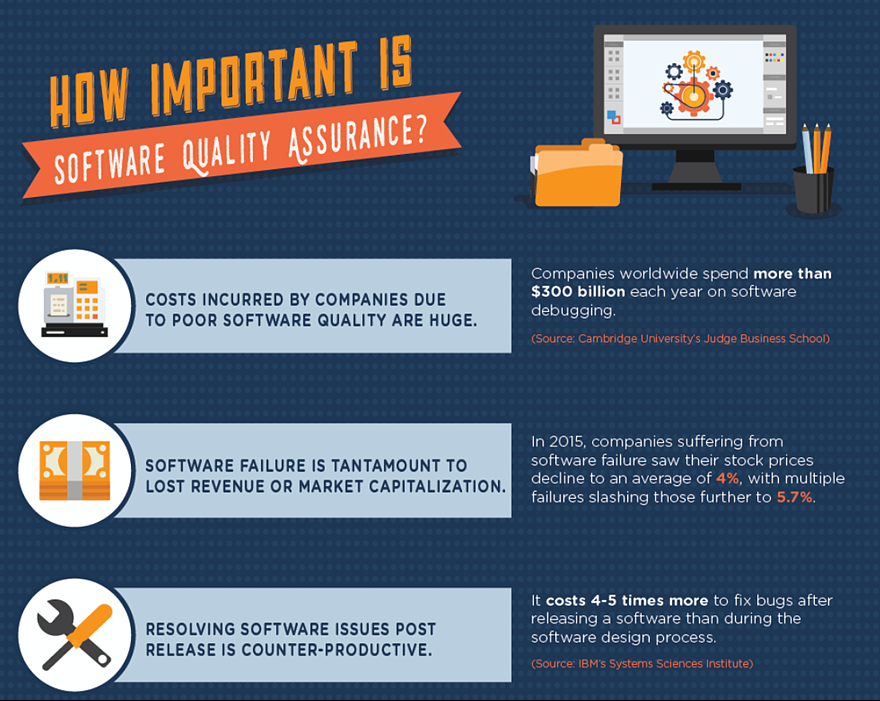

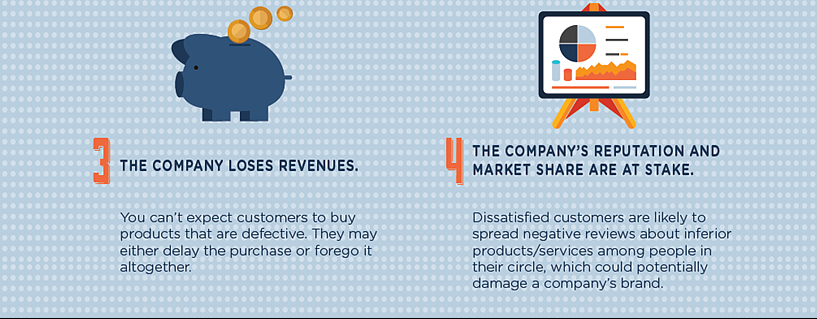

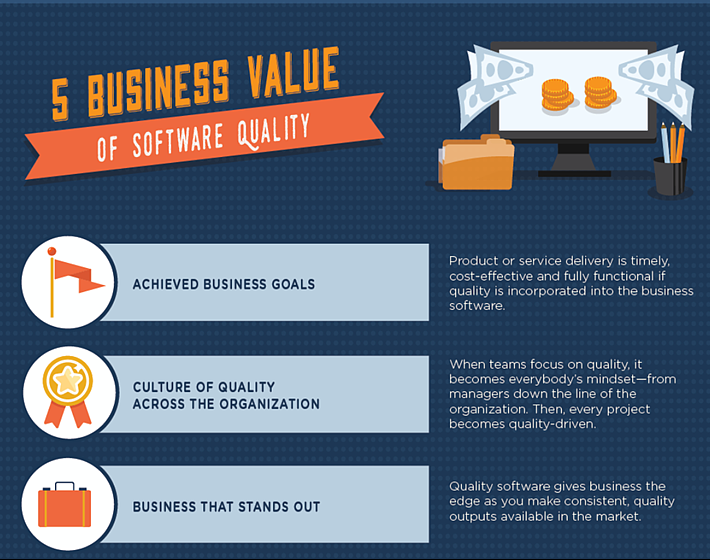

Chapter 1: Never Pass Defective Products

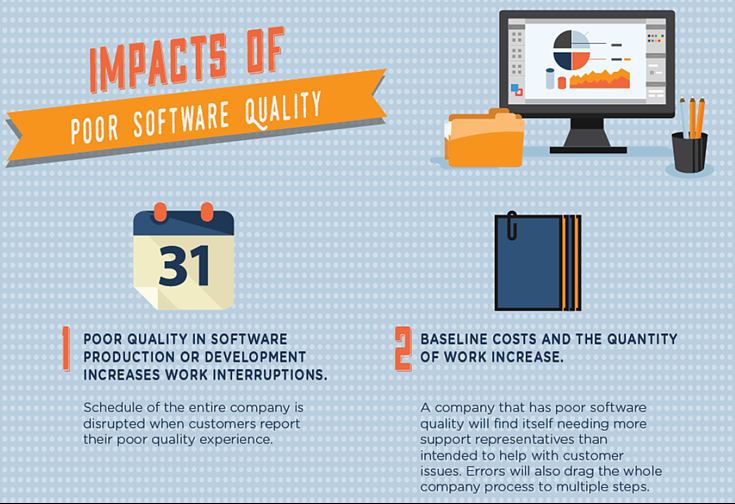

Products and services that fall short of the criteria and degree of quality required should not be passed by upstream procedures. Products having flaws ought to be taken off the production line and handled elsewhere. This prevents waste, reduces consumer complaints, and assures that only high-quality products are delivered to your customers.

Policies aid in ensuring that the required standard of quality is upheld at all times. In the case of manufacturing tangible items, this is quite simple. The same is true for knowledge work, though.

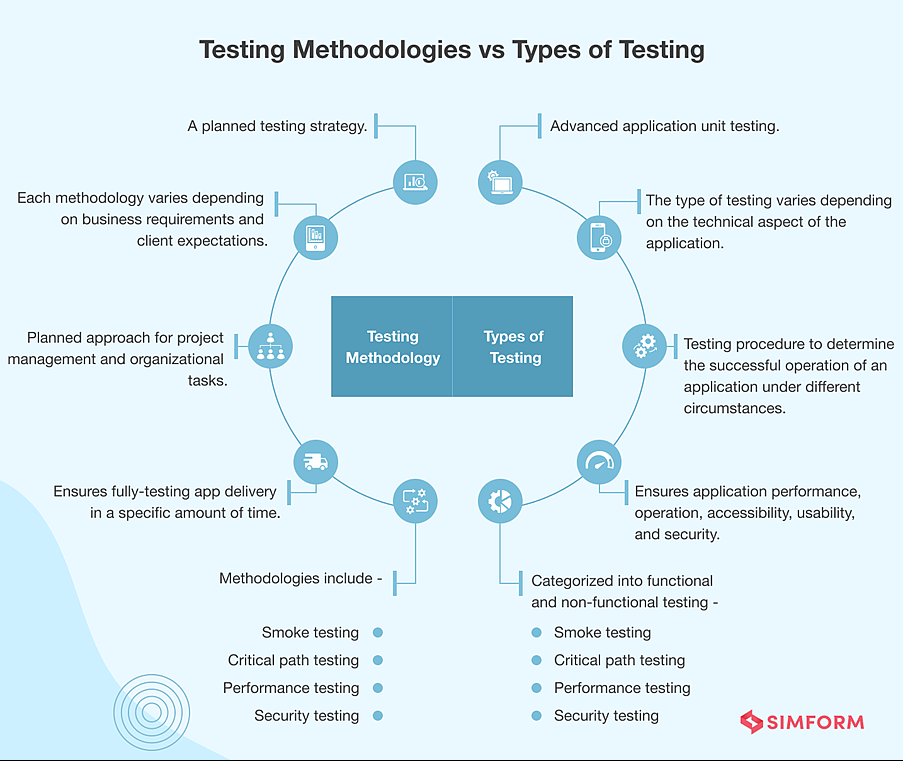

Applications, for instance, go through extensive quality assurance testing before being deployed in software development. Functional, regression, integration, performance, and stress testing are just a few examples of testing types. The only time they can put features and improvements on the market is if the team decides that they all need to pass these levels of testing.

Making a product as high-quality as feasible is always a company’s goal while producing or developing a good or service. High-quality goods increase consumer happiness, which improves reviews and reputation and may increase future sales. Nevertheless, whether you are producing chairs, medical equipment, bicycles, or everything in between, there is always a potential that your product will be flawed.

But how can you handle these faulty goods in the best way while minimizing the harm they cause to your company? Here are a few pointers for coping with damaged products for businesses.

Never Intentionally Ship a Defective Product

Make sure you never knowingly ship a defective product as your initial step. Giving customers a product that you know isn’t right is failing them severely, even if your shipment date is drawing near. If enough people purchase things with a flaw, it could affect both people and your reputation.

Additionally, you can be subject to legal action if the flawed goods causes harm to someone as a result of their use. Claiming ignorance could be challenging, especially if numerous other people also receive bad merchandise.

Suits frequently have a strict responsibility or negligence defense. This implies that in order to perhaps succeed in a case, a person will not need to demonstrate carelessness on your part. That’s because it’s your duty to make sure everything you sell is secure for the purpose for which it was designed. So it is never a good idea to ship something out with a problem, no matter how minor or unimportant the issue may be.

Complete Thorough Inspections and Testing

Preventing the occurrence of defective products in the first place is one of the greatest strategies to handle them. For all of your products, this is accomplished by establishing stringent testing and inspection procedures. Testing is crucial since it can make sure your product is secure, legal, trustworthy, long-lasting, and prepared for sale. Products should go through several tests and inspections during the manufacturing process, as well as once more before they are shipped.

Before assembly starts, it’s crucial to inspect any outsourced or raw materials that will go into your product. This will assist in finding any problems before they are manufactured, which will ultimately save time and money. Given that mistakes are unavoidable, additional testing must be done more frequently in order to improve results and stop the distribution of faulty goods.

Get Ahead of the Issue

Even while businesses frequently try their best to provide high-quality goods, occasionally there are flaws that go undiscovered. If that occurs, it’s critical to act swiftly to head off the issue. Once the flaw has been found, you might need to get in touch with your consumers or issue a public notification. Accept returns without posing any inquiries. Try to be as sympathetic as you can, and avoid becoming defensive or rejecting the issue.

It can have serious repercussions for your business, including negative publicity and internet discussion, if you don’t accept returns or if you try to cover up any wrongdoing. If at all possible, avoid receiving negative feedback as it can have a significant negative impact on a company’s reputation. The overall impact of the occurrence will be less negative the better you address a fault and set things right. In conclusion, it might be challenging for firms to deal with a damaged product. By lowering the likelihood that a flaw will make it onto one of your finished products, the knowledge in this course manual will assist in keeping your clients secure and upholding your solid reputation.

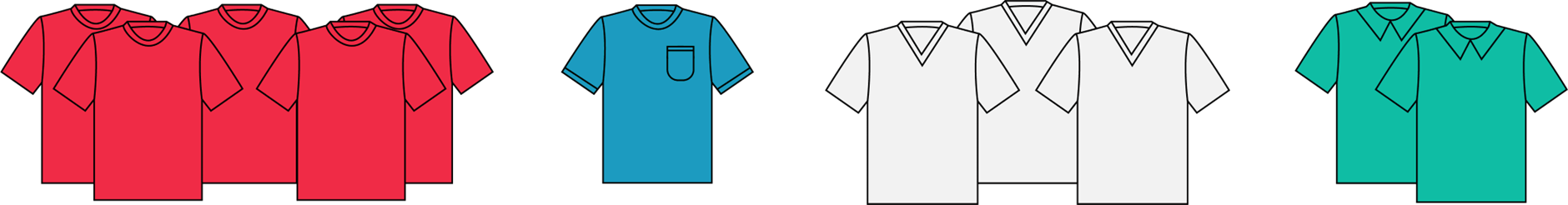

Chapter 2: Take Only What’s Needed

Only pulling what is required is essential for a successful Kanban implementation. By doing this, overproduction is avoided, expenses are reduced, and operations are better suited to meet market demands.

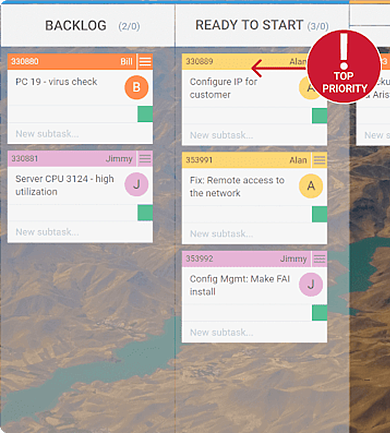

It is relatively simple to implement this rule as one of the six Kanban rules for manufacturing processes. We might think of this in terms of knowledge work as merely focusing on client requests or orders as necessary. This entails adhering to the order of importance in your backlog.

Lean believes it is wasteful to have a backlog of ideas in order. How can that be a waste? Well, it takes time to continually strive to prioritize and polish an unending supply of ideas. What if they are never put into practice? Time squandered is the obvious solution.

However, you still need a mechanism to record your ideas, including customer feedback, when working on a project, product, or service. Otherwise, you run the risk of gathering significant amounts of disarray and misinterpretation of the true needs of the customer. That most certainly wouldn’t keep you on the proper track to agility for very long.

Therefore, use the Kanban backlog to gather and organize your ideas in order to reduce confusion. It enables you to continuously give value to customers and lessen the uncertainty of the work process.

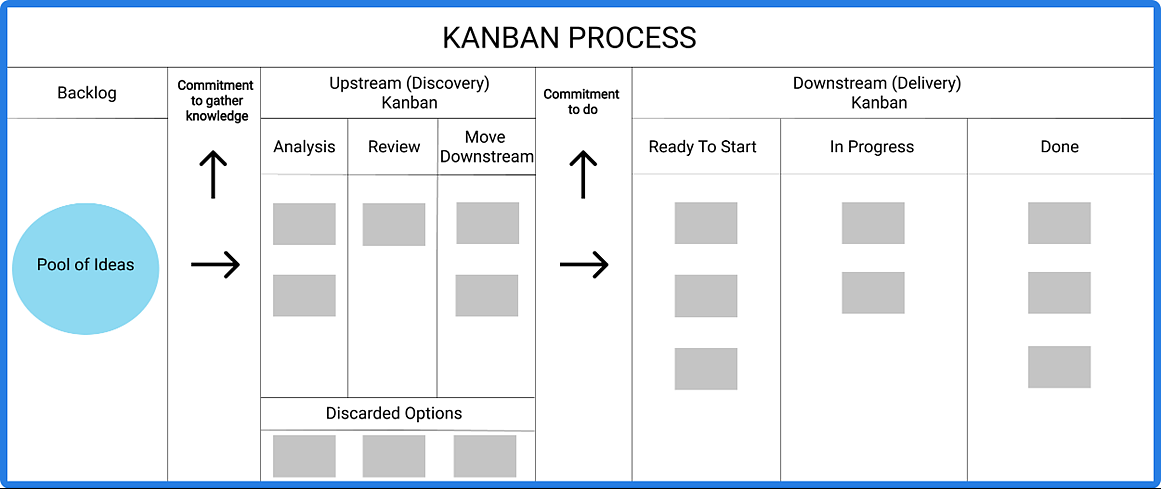

What Is the Purpose of the Kanban Backlog?

A project or product backlog is a visual depiction of the things you might or might not deliver, according to definition. The backlog “lives” on the leftmost area of a Kanban board, before the “To Do” stage (column).

When you move work from the Backlog to the “To Do” column, it means that you have all the necessary information and are certain you can complete it effectively (while ensuring good quality). Once the item enters the “In progress” stage, you are then committed to finishing it by the specified SLA (Service Level Agreement).

Having said that, it is important to note that the Kanban backlog serves more than just as a list of ideas and client feedback. Your goal should be to gradually make ideas more doable so that you may ultimately make them a reality.

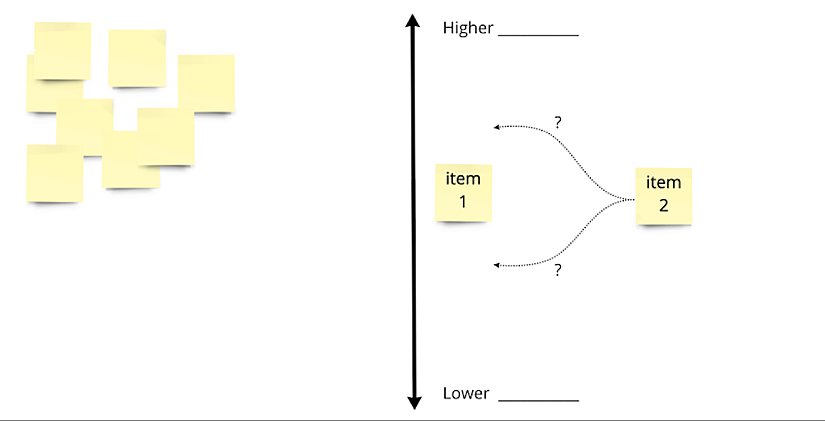

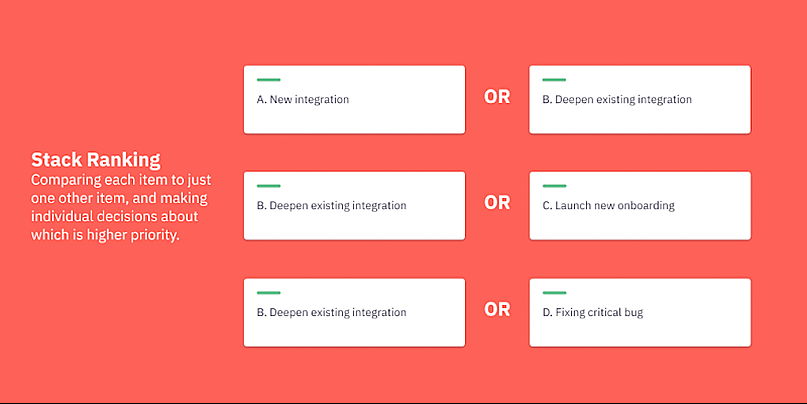

Backlog Prioritization

Everything in the backlog needs to be preserved in a meaningful order, and this should be done with the least amount of work necessary. To do this, several priority levels might be established.

You can make a different graphic board to act as your backlog in the event that you need to assemble a sizable collection of ideas. Because there won’t be any work flow there, this won’t be a Kanban board. Simply use it as a tool to prioritize and better illustrate your rough ideas and client input.

Once your board is set up, you can divide it into columns to symbolize the various types of work and swimlanes to indicate the various levels of priority. Examples are High, Medium, and Low. The goods that are more in demand, demand more work, and provide more value to clients should be placed higher in the list of ideas.

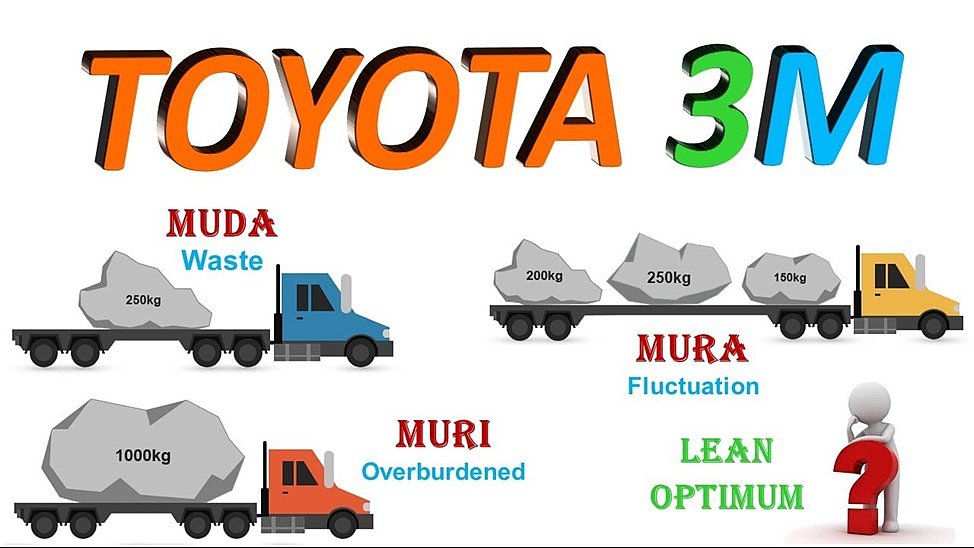

Chapter 3: Produce the Exact Quantity Required

The third of the six Kanban rules complements the second. Taking only what you need would result in only producing the precise amount of goods needed. What are you going to do with the extra inventory if you overproduce? You’re stockpiling more expenses. These include the opportunity costs incurred from the materials and funds used to construct the product, as well as storage and shipping expenses. Additionally, there is a chance that the item will degrade or become outdated.

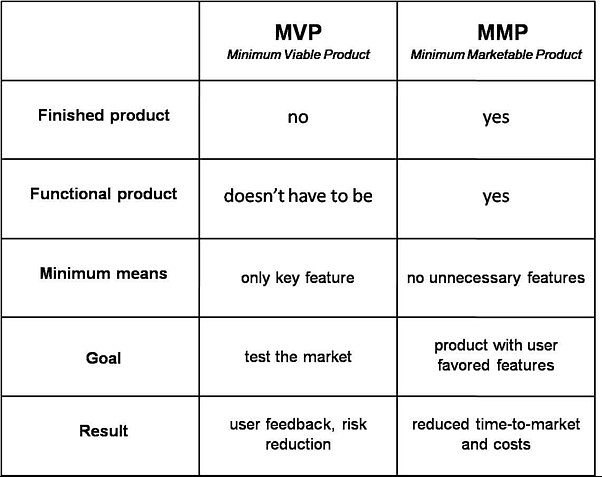

How does this relate to the process of knowledge? In this regard, adopting a Minimum Viable Product (MVP) approach is beneficial. You don’t need to include a print capability if a customer only wants the ability to download reports from your app, for instance. Keep your attention on the bare minimums. As the market requires or as your product strategy dictates, you can add to the product.

Minimum Viable Product (MVP)

A notion from the lean startup methodology known as a minimum viable product (MVP) emphasizes the importance of learning in the creation of new products. An MVP, according to Eric Ries, is the iteration of a new product that enables a team to get the most verified data about customers with the least amount of work. Whether your customers will actually buy your product is how you may validate your learning.

A fundamental tenet of the MVP concept is that you create a real product—which could be as simple as a landing page or a service that appears to be automated but is actually entirely manual—that you can offer to customers and watch how they actually use it. Asking individuals what they would do is significantly less reliable than observing what they really do in relation to a product.

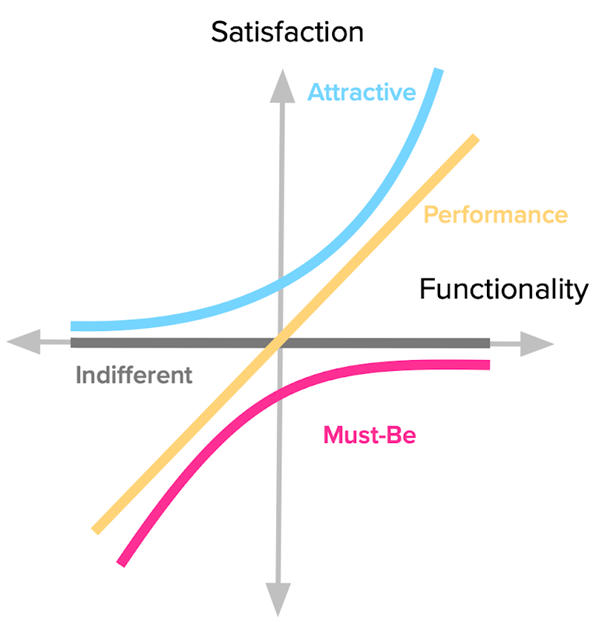

Expected Benefits

An MVP’s main advantage is that it allows you to gauge customer interest in your product before it has been fully developed. You will spend less time and money developing a product that won’t sell if you can determine sooner whether consumers will find it appealing.

Common Pitfalls

Teams use the phrase MVP but don’t always understand what it means or is supposed to mean. This ignorance frequently takes the form of thinking that an MVP is the bare minimum of functionality they can provide, without the additional criterion of being sufficient to comprehend the product’s commercial viability.

A Minimum Marketable Feature (MMF) or Minimum Marketable Product (MMP), which has a focus on income, may be mistaken with an MVP, which has a focus on learning. Unless the team gets overly focused on delivering something without taking into account whether it is the appropriate something that satisfies the customer’s needs, there is not much harm in this.

Teams place more emphasis on the MVP’s minimum requirements than its viable components. The quality of the product that was given was insufficient to determine whether buyers would actually use it.

Teams deliver what they view as an MVP, but after that, regardless of the criticism they hear, they stop making adjustments to that product.

Potential Costs

When an MVP is used properly, a team may drastically alter the product they give to their clients or even discard it altogether in response to the feedback they get. In order to avoid developing a product that no one will buy, the MVP’s minimum element pushes teams to work as little as possible to get relevant feedback (Eric Ries refers to this as validated learning).

Origins

2009: Eric Ries’ description of MVP in his book The Lean Startup helped the idea become more well-known.

Signs of Use

The MVP serves as the cornerstone of a team’s experimental approach. They postulate that the product the team is working on fills a need that their clients may have. In order to determine whether the clients would actually utilize the product to meet their demands, the team then offers something to those customers. The team decides whether to continue, change, or stop working on the product in light of the knowledge obtained from this trial.

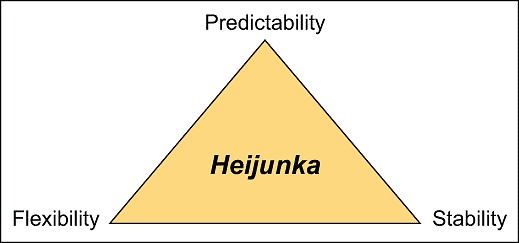

Chapter 4: Level the Production

Even if everything was equal, nothing would be. Unexpected catastrophes, intrinsic faults, and a high propensity for incorrect estimation exist. Should we give up and let your company continue to lose money as a result of these factors? No! You will be reading this course handbook on leveling production as a result.

What is Production Leveling?

Production smoothing, also known as production leveling, is the process by which businesses meet consumer needs while minimizing production wastes, such as capital expenses, labor costs, and lead times for manufacturing.

The term “production leveling” is derived from the Japanese word “Heijunka” which means “leveling” and refers to a waste-reduction approach.

The goal of the process is to create goods at a constant rate so that additional processing is done at a consistent and predictable rate in an effort to meet high demand. In order to reduce production fluctuations, experts agree that this method is best applied in the final production line.

Approaches to Production Leveling

Volume Leveling

Assume you are a mobile phone manufacturer and you are given the task of delivering 500 units of your phone to a certain client each week, 200 units on Monday, 100 units on Tuesday, 50 units on Wednesday, 100 units on Thursday, and 50 units on Friday.

All you have to do is stock 100 items close to delivery every Monday in accordance with the demand leveling principle. There is always a supply of 100 pieces ready on Monday mornings as a result. The manufacturing crew then continues to consistently create 100 pieces of the items each day for the rest of the week. This lowers the cost of capital as well as other production procedures.

Product Leveling

Assuming you are manufacturing various electronics devices, managing this may seem like an impossible chore. However, this difficulty can be overcome by shortening the intervals between equipment takeovers and providing for buffering. This helps you level the lead time and stock accumulation while also lowering expenditures.

The Heijunka Box

The secret to slashing lead times in organizations is heijunka. Manufacturing companies can better satisfy customer demand when this is done correctly and items are delivered in a timely manner. It includes taking a buffer inventory as soon as it is due, working slowly and consistently, and observing takt time.

Chapter 5: Process Optimization – Lead & Cycle Time

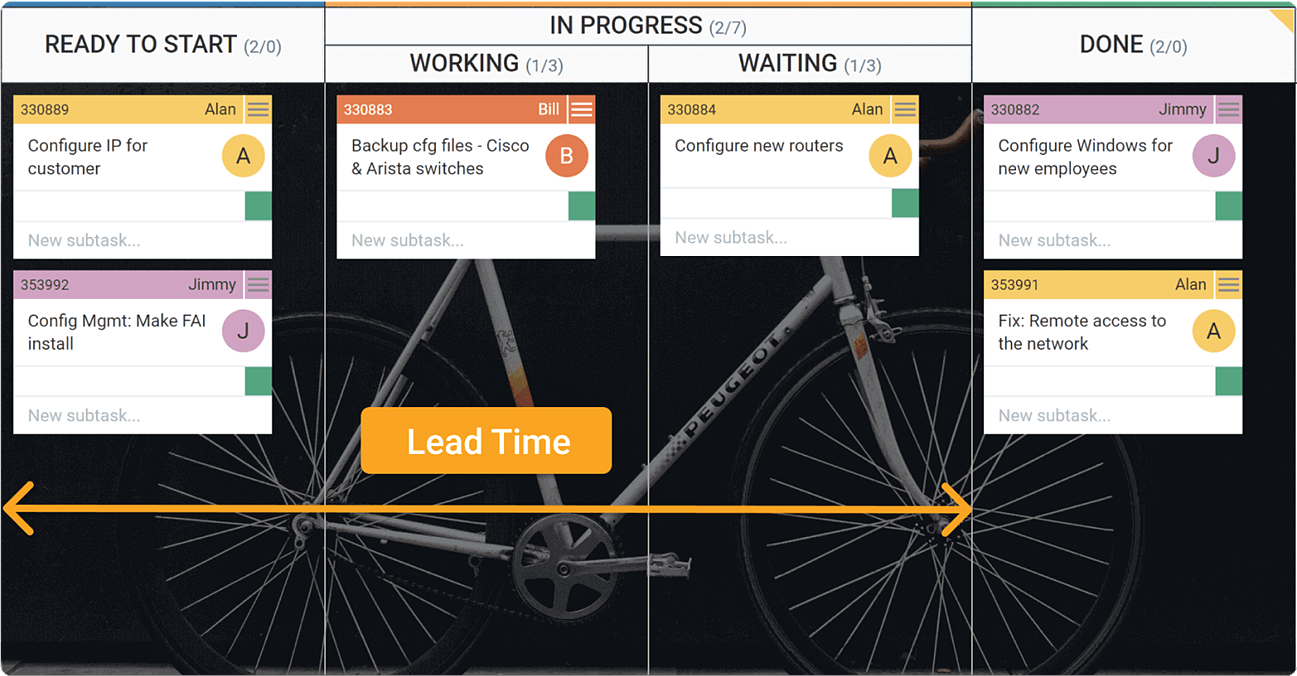

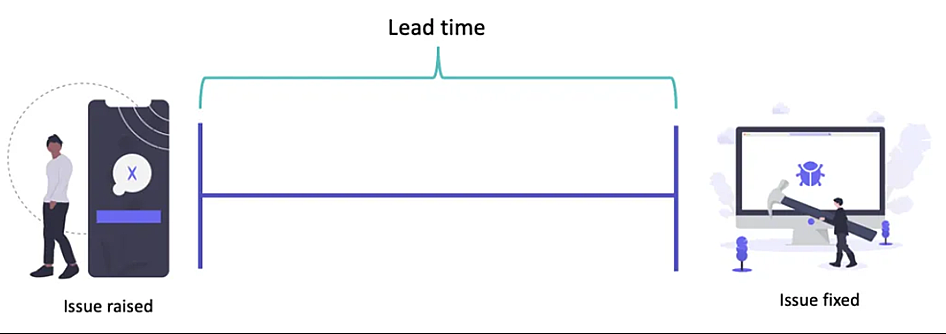

The phrase “lead time” is taken from the Toyota Production System, which defines it as the period of time between a customer placing an order and delivering the ordered product.

In the context of software, lead time can be more broadly defined as the amount of time between the identification of a demand and its fulfillment. Determining a more precise measurement relies on the context being studied. For example, when concentrating on the software development process, the “lead time” elapsed between the creation of a user narrative and that story being used “in production,” that is, by actual users under typical circumstances, is important to consider.

Teams using the kanban method prefer this metric to the more well-known velocity. Improvement projects strive to decrease lead time rather than boost velocity.

Also Known As:

Some writers distinguish between “cycle time” and “lead time.” The time between making a request and having it fulfilled is measured from the “user’s point of view” in the first case, and the time between starting work on a user story and making the feature available for delivery is measured from the “developer’s point of view” in the second.

Given the wide variety of software endeavors, these criteria are currently in flux and may differ dramatically from one software development team to another. The best course of action is probably to carefully select one measurement method and make sure that everyone, at the very least within a specific team, is aware of how and why it is being utilized.

In the field of Kanban, the words lead time and cycle time are frequently employed and serve as crucial strategic KPIs for project management. However, project managers frequently struggle to distinguish between them and their significance. When this course manual is complete, you will:

• distinguish the metrics easily and use them properly;

• learn why the difference between lead time and cycle time matters;

• understand how to measure both metrics.

Defining Cycle Time and Lead Time

In the Lean methodology, cycle time and lead time are two crucial measures. You can have a better understanding of how work moves over time by measuring a process’ cycle and lead times. The study can show where process issues are and how to fix them to ensure that goods and services are delivered to customers on time.

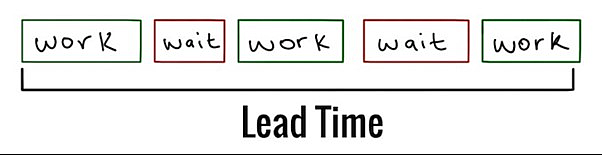

What Is Lead Time?

Lead Time Definition:

The lead time is the period of time between the request for a new work item and its completion.

When a team member commits to a new work request (the request has left the backlog and is at a commitment stage in the process), it is advised to measure lead time in Kanban.

In a Kanban system, the average lead time will be considerably more precisely calculated in this way. Otherwise, you risk having hundreds of new work items sit in a waiting queue for months before anyone has the time to begin them. Lead times will consequently rise sharply.

What Is Cycle Time?

Cycle Time Definition:

Cycle Time is the amount of time a team/ person spends actually working on a work item up until it is ready for delivery.

Lead time measures the entire process since the arrival of new demand, whereas cycle time examines those portions of the process where teams are actively adding value to the task at hand. To put it another way, on a Kanban board, the work item normally flips to “in progress” whenever the cycle time meter starts to gather data.

You must monitor your total WIP if you want to maintain a constant cycle time. Professor John Little, an Institute Professor at MIT, came to the conclusion that the cycle time of the system increases with the amount of work that is in progress.

The equation became famous as Little’s law, and the cycle time formula looks like this:

Cycle Time = Work in Progress / Throughput*

*In the formula above, throughput is the total number of work items that pass through the process over a certain period of time. Work in progress (WIP), on the other hand, looks at how much active work lives in the system on average.

Chapter 6: Process Optimization – Throughput

What Is Throughput?

The quantity of a product or service that a company can create and deliver to a customer within a predetermined time frame is known as throughput in the business world. The phrase is frequently used in reference to a business’s production rate or the rate at which something is processed.

Because high throughput typically suggests that a company can provide a good or service more effectively than its rivals, businesses with high throughput levels can steal market share from their lower throughput peers.

Understanding Throughput

In business management, the concept of throughput, commonly referred to as flow rate, is included in the theory of limitations. This idea is based on the axiom that any link in a chain can only be as strong as its weakest counterpart. The aim of business managers is to increase throughput for the product’s end users while minimizing the impact of the weakest connections on a company’s success. A corporation can achieve revenue maximization after throughput is maximized by eliminating inefficiencies, allowing inputs and outputs to flow in the most appropriate way.

Throughput and a company’s production capacity are closely tied, and management might make various assumptions about capacity. Management is employing theoretical capacity when it expects that production will run continuously and without any breaks, yet this level of capacity is not achievable. Because equipment needs to be maintained and repaired, as well as because workers require time off, no industrial process can ever operate at maximum output. Using practical capacity, which takes into account machine repairs, wait times, and holidays, is more realistic for enterprises.

Factors Affecting Throughput

The efficiency with which a business handles its supply chain, which is the relationship it has with its suppliers, also affects how much business it can process. Throughput is negatively impacted when materials are not accessible as a manufacturing input, regardless of the cause.

Two items may frequently begin production using the same technique, in which case the shared expenses are divided among the two products. However, the goods are created utilizing different procedures until production reaches the split-off point. It is more challenging to maintain a high throughput in this circumstance.

Benefits of Knowing Throughput Time

The term “throughput time” describes the overall amount of time needed to complete a specific process from beginning to end. For instance, a manufacturer can determine how long it takes to make a product, from the time the customer places the initial order to the time the product is manufactured and sold.

The following elements make up throughput time in further detail:

• Processing time is how long all of the steps of producing a good or service take

• Inspection time involves running quality control and monitoring finished goods

• Move time includes how long it takes to transport, ship, and deliver items across the logistics chain

• Queue time, or wait time, is computed as all idle time in between these other components.

You may calculate the overall throughput time by adding these. Company managers can address bottlenecks, slowdowns, and backlogs to increase productivity if they can spot these areas. Faster throughput times boost profitability and return on investment (ROI).

Chapter 7: Kanban Metrics Charts

Cumulative flow diagrams allow you to quickly view the full of your workflow and are helpful tools for diagnosing issues with your processes, as we explored in the previous course handbook. You may decrease your average cycle time, control your WIP limitations, and boost team throughput by using a cumulative flow diagram.

What does a cumulative flow diagram show?

In the Kanban methodology, Kanban boards are used to separate a project’s workflow into three columns: tasks that are “To Do,” “Work in Progress,” and “Done.” Every activity that has passed through your process is gathered in cumulative flow diagrams to show three crucial metrics:

• Cycle time: This is the total time it takes your team to complete each task from the beginning to the end. One of the benefits of CFDs is that you can see where you can optimize your workflow to reduce cycle times.

• Work in progress: This is the number of tasks your team is actively handling at a certain time. Cumulative flow diagrams will visualize inefficiencies in your project timeline when your team has too much or too little work in progress at any given point.

• Throughput: This is the number of tasks your team can complete over a given period. As this is the ultimate measure of your team’s productivity, cumulative flow diagrams should show where you can align your efforts and resources so that throughput increases over time.

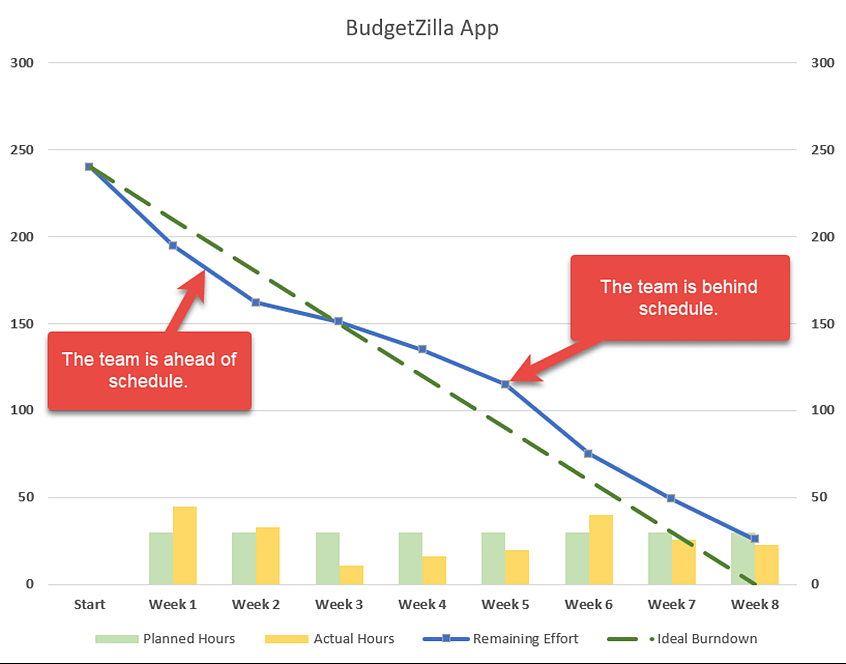

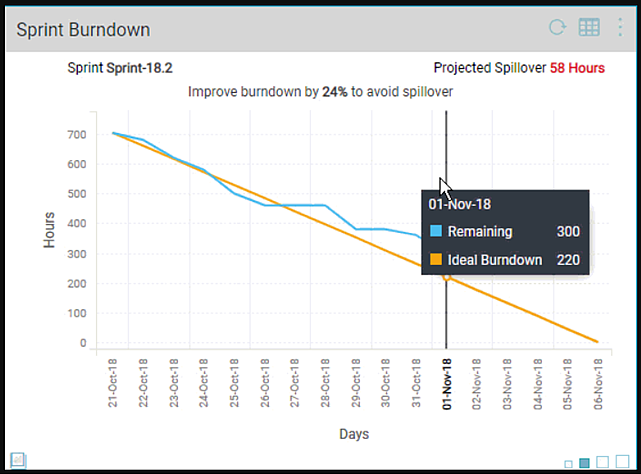

Burndown Chart

Agile burndown charts keep track of the amount of work still to be done on a sprint or project and the amount of time the team will need to do it. Agile project managers, product managers, and other team leads frequently utilize them to maintain deadlines, spot problems as they arise, and make strategic plans for each sprint or project.

Burndown charts can be divided into two categories: sprint burndowns, which measure work for a particular sprint, and product burndowns, which track work for an entire product project.

The amount of work that needs to be done is represented by the y-axis (vertical) in both forms of burndown charts, while the time permitted is shown on the x-axis. Your beginning point is in the top left corner, and the finished product is at the bottom right.

The ideal work remaining is typically shown as a straight line from beginning to end (essentially, what will happen if you work on the project steadily from beginning to end without delays or speed-ups). The real work is represented by a second line, which is generally always less linear due to activities that go surprisingly quickly or slowly, interruptions, and innovations.

These lines will be used by your project manager to compare expectations to reality and make adjustments as necessary for this sprint, the whole project, and subsequent projects. It is always preferable to compare and contrast your project end point with an actual work remaining line on a burndown chart.

Burndown vs. Burnup: What’s the Difference?

In contrast to a burndown chart, which shows how much work is still left on each project, a burnup chart shows how much work has already been completed on a project or toward a goal.

Although they often serve different purposes, both can be effective ways to visualize progress. Project managers can spot estimating problems early and determine how much work and effort is still needed by using burndown charts. Burnup charts encourage teams by displaying advancement toward a target.

In other words, burnup informs the squad that they are only a short distance from the goal. Project managers can use burndown to determine whether they have accurately timed the team’s arrival at the finish line and mapped the terrain.

Depending on the data you decide to include, you can utilize both charts in comparable ways. Ultimately, teams can opt to work with either or both charts, depending on their preferences, even if it may be the standard to utilize burndown for strategic planning and burnup for team motivation.

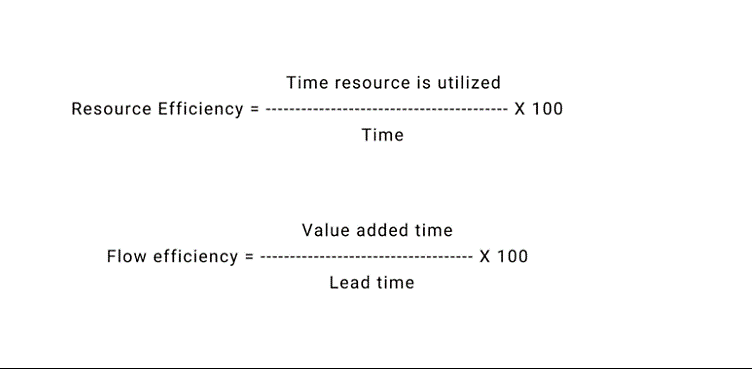

Flow Efficiency

Flow Efficiency in Kanban enables you to calculate the actual time you have spent on a task. Therefore, the efficiency is determined by comparing the actual work time to the overall wait time. Higher the flow efficiency %, the better and more fluid the process is able to transform an idea or request into a usable feature.

With the exception of Wait Time and Blocked Time, you can use Flow Efficiency Analytics to examine the actual production time for cards.

As an illustration, you could compare the percentage of time spent on cards that are normally in the In-Progress column type to the overall time spent on the board by such cards.

To calculate the total flow efficiency for the chosen time period, the chart will automatically collect data from each card that moved across your Kanban board during that time.

The flow efficiency (%) of your process determines how quickly tasks move through it. Teams can assess their improvement efforts by monitoring flow efficiency over time.

The flow efficiency chart illustrates the ratio of time spent working actively vs time spent waiting on work items.

The value stream is intended to be reflected on kanban boards. Value streams map both the queues between activities and the activities themselves.

How do we know if a work item is waiting? There are columns on the Kanban board, which were marked as “queue” ones, during the Board customization. When cards are waiting in these columns, they generate non-value-added time.

Some examples of “Queue” Kanban columns may be:

• Waiting for Approval – This type of Kanban queue column is appropriate for tasks that require approval to be processed (e.g. payments, promotional sales, etc.)

• Waiting for Review – This Kanban queue is a relevant stage of the workflow where work items wait to be evaluated. It is like a filter before tasks receive feedback and move forward to the completion stage or go back for improvements. It plays a crucial role in product/service’s quality (e.g. product development, content writing, design, etc.)

• Waiting for External Activity – This kind of Kanban column is applicable for tasks waiting for third-party actions in order to be completed. It happens often when a team communicates with other units outside of the company. (e.g. partnerships, affiliate programs, etc.)

Curriculum

Leading IT Transformation – Workshop 21 – Fine-Tuning Kanban

- Never Pass Defective Products

- Take Only What’s Needed

- Produce the Exact Quantity Required

- Level the Production

- Process Optimization – Lead & Cycle Time

- Process Optimization – Throughput

- Kanban Metrics Charts

Distance Learning

Introduction

Welcome to Appleton Greene and thank you for enrolling on the Leading IT Transformation corporate training program. You will be learning through our unique facilitation via distance-learning method, which will enable you to practically implement everything that you learn academically. The methods and materials used in your program have been designed and developed to ensure that you derive the maximum benefits and enjoyment possible. We hope that you find the program challenging and fun to do. However, if you have never been a distance-learner before, you may be experiencing some trepidation at the task before you. So we will get you started by giving you some basic information and guidance on how you can make the best use of the modules, how you should manage the materials and what you should be doing as you work through them. This guide is designed to point you in the right direction and help you to become an effective distance-learner. Take a few hours or so to study this guide and your guide to tutorial support for students, while making notes, before you start to study in earnest.

Study environment

You will need to locate a quiet and private place to study, preferably a room where you can easily be isolated from external disturbances or distractions. Make sure the room is well-lit and incorporates a relaxed, pleasant feel. If you can spoil yourself within your study environment, you will have much more of a chance to ensure that you are always in the right frame of mind when you do devote time to study. For example, a nice fire, the ability to play soft soothing background music, soft but effective lighting, perhaps a nice view if possible and a good size desk with a comfortable chair. Make sure that your family know when you are studying and understand your study rules. Your study environment is very important. The ideal situation, if at all possible, is to have a separate study, which can be devoted to you. If this is not possible then you will need to pay a lot more attention to developing and managing your study schedule, because it will affect other people as well as yourself. The better your study environment, the more productive you will be.

Study tools & rules

Try and make sure that your study tools are sufficient and in good working order. You will need to have access to a computer, scanner and printer, with access to the internet. You will need a very comfortable chair, which supports your lower back, and you will need a good filing system. It can be very frustrating if you are spending valuable study time trying to fix study tools that are unreliable, or unsuitable for the task. Make sure that your study tools are up to date. You will also need to consider some study rules. Some of these rules will apply to you and will be intended to help you to be more disciplined about when and how you study. This distance-learning guide will help you and after you have read it you can put some thought into what your study rules should be. You will also need to negotiate some study rules for your family, friends or anyone who lives with you. They too will need to be disciplined in order to ensure that they can support you while you study. It is important to ensure that your family and friends are an integral part of your study team. Having their support and encouragement can prove to be a crucial contribution to your successful completion of the program. Involve them in as much as you can.

Successful distance-learning

Distance-learners are freed from the necessity of attending regular classes or workshops, since they can study in their own way, at their own pace and for their own purposes. But unlike traditional internal training courses, it is the student’s responsibility, with a distance-learning program, to ensure that they manage their own study contribution. This requires strong self-discipline and self-motivation skills and there must be a clear will to succeed. Those students who are used to managing themselves, are good at managing others and who enjoy working in isolation, are more likely to be good distance-learners. It is also important to be aware of the main reasons why you are studying and of the main objectives that you are hoping to achieve as a result. You will need to remind yourself of these objectives at times when you need to motivate yourself. Never lose sight of your long-term goals and your short-term objectives. There is nobody available here to pamper you, or to look after you, or to spoon-feed you with information, so you will need to find ways to encourage and appreciate yourself while you are studying. Make sure that you chart your study progress, so that you can be sure of your achievements and re-evaluate your goals and objectives regularly.

Self-assessment

Appleton Greene training programs are in all cases post-graduate programs. Consequently, you should already have obtained a business-related degree and be an experienced learner. You should therefore already be aware of your study strengths and weaknesses. For example, which time of the day are you at your most productive? Are you a lark or an owl? What study methods do you respond to the most? Are you a consistent learner? How do you discipline yourself? How do you ensure that you enjoy yourself while studying? It is important to understand yourself as a learner and so some self-assessment early on will be necessary if you are to apply yourself correctly. Perform a SWOT analysis on yourself as a student. List your internal strengths and weaknesses as a student and your external opportunities and threats. This will help you later on when you are creating a study plan. You can then incorporate features within your study plan that can ensure that you are playing to your strengths, while compensating for your weaknesses. You can also ensure that you make the most of your opportunities, while avoiding the potential threats to your success.

Accepting responsibility as a student

Training programs invariably require a significant investment, both in terms of what they cost and in the time that you need to contribute to study and the responsibility for successful completion of training programs rests entirely with the student. This is never more apparent than when a student is learning via distance-learning. Accepting responsibility as a student is an important step towards ensuring that you can successfully complete your training program. It is easy to instantly blame other people or factors when things go wrong. But the fact of the matter is that if a failure is your failure, then you have the power to do something about it, it is entirely in your own hands. If it is always someone else’s failure, then you are powerless to do anything about it. All students study in entirely different ways, this is because we are all individuals and what is right for one student, is not necessarily right for another. In order to succeed, you will have to accept personal responsibility for finding a way to plan, implement and manage a personal study plan that works for you. If you do not succeed, you only have yourself to blame.

Planning

By far the most critical contribution to stress, is the feeling of not being in control. In the absence of planning we tend to be reactive and can stumble from pillar to post in the hope that things will turn out fine in the end. Invariably they don’t! In order to be in control, we need to have firm ideas about how and when we want to do things. We also need to consider as many possible eventualities as we can, so that we are prepared for them when they happen. Prescriptive Change, is far easier to manage and control, than Emergent Change. The same is true with distance-learning. It is much easier and much more enjoyable, if you feel that you are in control and that things are going to plan. Even when things do go wrong, you are prepared for them and can act accordingly without any unnecessary stress. It is important therefore that you do take time to plan your studies properly.

Management

Once you have developed a clear study plan, it is of equal importance to ensure that you manage the implementation of it. Most of us usually enjoy planning, but it is usually during implementation when things go wrong. Targets are not met and we do not understand why. Sometimes we do not even know if targets are being met. It is not enough for us to conclude that the study plan just failed. If it is failing, you will need to understand what you can do about it. Similarly if your study plan is succeeding, it is still important to understand why, so that you can improve upon your success. You therefore need to have guidelines for self-assessment so that you can be consistent with performance improvement throughout the program. If you manage things correctly, then your performance should constantly improve throughout the program.

Study objectives & tasks

The first place to start is developing your program objectives. These should feature your reasons for undertaking the training program in order of priority. Keep them succinct and to the point in order to avoid confusion. Do not just write the first things that come into your head because they are likely to be too similar to each other. Make a list of possible departmental headings, such as: Customer Service; E-business; Finance; Globalization; Human Resources; Technology; Legal; Management; Marketing and Production. Then brainstorm for ideas by listing as many things that you want to achieve under each heading and later re-arrange these things in order of priority. Finally, select the top item from each department heading and choose these as your program objectives. Try and restrict yourself to five because it will enable you to focus clearly. It is likely that the other things that you listed will be achieved if each of the top objectives are achieved. If this does not prove to be the case, then simply work through the process again.

Study forecast

As a guide, the Appleton Greene Leading IT Transformation corporate training program should take 12-18 months to complete, depending upon your availability and current commitments. The reason why there is such a variance in time estimates is because every student is an individual, with differing productivity levels and different commitments. These differentiations are then exaggerated by the fact that this is a distance-learning program, which incorporates the practical integration of academic theory as an as a part of the training program. Consequently all of the project studies are real, which means that important decisions and compromises need to be made. You will want to get things right and will need to be patient with your expectations in order to ensure that they are. We would always recommend that you are prudent with your own task and time forecasts, but you still need to develop them and have a clear indication of what are realistic expectations in your case. With reference to your time planning: consider the time that you can realistically dedicate towards study with the program every week; calculate how long it should take you to complete the program, using the guidelines featured here; then break the program down into logical modules and allocate a suitable proportion of time to each of them, these will be your milestones; you can create a time plan by using a spreadsheet on your computer, or a personal organizer such as MS Outlook, you could also use a financial forecasting software; break your time forecasts down into manageable chunks of time, the more specific you can be, the more productive and accurate your time management will be; finally, use formulas where possible to do your time calculations for you, because this will help later on when your forecasts need to change in line with actual performance. With reference to your task planning: refer to your list of tasks that need to be undertaken in order to achieve your program objectives; with reference to your time plan, calculate when each task should be implemented; remember that you are not estimating when your objectives will be achieved, but when you will need to focus upon implementing the corresponding tasks; you also need to ensure that each task is implemented in conjunction with the associated training modules which are relevant; then break each single task down into a list of specific to do’s, say approximately ten to do’s for each task and enter these into your study plan; once again you could use MS Outlook to incorporate both your time and task planning and this could constitute your study plan; you could also use a project management software like MS Project. You should now have a clear and realistic forecast detailing when you can expect to be able to do something about undertaking the tasks to achieve your program objectives.

Performance management

It is one thing to develop your study forecast, it is quite another to monitor your progress. Ultimately it is less important whether you achieve your original study forecast and more important that you update it so that it constantly remains realistic in line with your performance. As you begin to work through the program, you will begin to have more of an idea about your own personal performance and productivity levels as a distance-learner. Once you have completed your first study module, you should re-evaluate your study forecast for both time and tasks, so that they reflect your actual performance level achieved. In order to achieve this you must first time yourself while training by using an alarm clock. Set the alarm for hourly intervals and make a note of how far you have come within that time. You can then make a note of your actual performance on your study plan and then compare your performance against your forecast. Then consider the reasons that have contributed towards your performance level, whether they are positive or negative and make a considered adjustment to your future forecasts as a result. Given time, you should start achieving your forecasts regularly.

With reference to time management: time yourself while you are studying and make a note of the actual time taken in your study plan; consider your successes with time-efficiency and the reasons for the success in each case and take this into consideration when reviewing future time planning; consider your failures with time-efficiency and the reasons for the failures in each case and take this into consideration when reviewing future time planning; re-evaluate your study forecast in relation to time planning for the remainder of your training program to ensure that you continue to be realistic about your time expectations. You need to be consistent with your time management, otherwise you will never complete your studies. This will either be because you are not contributing enough time to your studies, or you will become less efficient with the time that you do allocate to your studies. Remember, if you are not in control of your studies, they can just become yet another cause of stress for you.

With reference to your task management: time yourself while you are studying and make a note of the actual tasks that you have undertaken in your study plan; consider your successes with task-efficiency and the reasons for the success in each case; take this into consideration when reviewing future task planning; consider your failures with task-efficiency and the reasons for the failures in each case and take this into consideration when reviewing future task planning; re-evaluate your study forecast in relation to task planning for the remainder of your training program to ensure that you continue to be realistic about your task expectations. You need to be consistent with your task management, otherwise you will never know whether you are achieving your program objectives or not.

Keeping in touch

You will have access to qualified and experienced professors and tutors who are responsible for providing tutorial support for your particular training program. So don’t be shy about letting them know how you are getting on. We keep electronic records of all tutorial support emails so that professors and tutors can review previous correspondence before considering an individual response. It also means that there is a record of all communications between you and your professors and tutors and this helps to avoid any unnecessary duplication, misunderstanding, or misinterpretation. If you have a problem relating to the program, share it with them via email. It is likely that they have come across the same problem before and are usually able to make helpful suggestions and steer you in the right direction. To learn more about when and how to use tutorial support, please refer to the Tutorial Support section of this student information guide. This will help you to ensure that you are making the most of tutorial support that is available to you and will ultimately contribute towards your success and enjoyment with your training program.

Work colleagues and family

You should certainly discuss your program study progress with your colleagues, friends and your family. Appleton Greene training programs are very practical. They require you to seek information from other people, to plan, develop and implement processes with other people and to achieve feedback from other people in relation to viability and productivity. You will therefore have plenty of opportunities to test your ideas and enlist the views of others. People tend to be sympathetic towards distance-learners, so don’t bottle it all up in yourself. Get out there and share it! It is also likely that your family and colleagues are going to benefit from your labors with the program, so they are likely to be much more interested in being involved than you might think. Be bold about delegating work to those who might benefit themselves. This is a great way to achieve understanding and commitment from people who you may later rely upon for process implementation. Share your experiences with your friends and family.

Making it relevant

The key to successful learning is to make it relevant to your own individual circumstances. At all times you should be trying to make bridges between the content of the program and your own situation. Whether you achieve this through quiet reflection or through interactive discussion with your colleagues, client partners or your family, remember that it is the most important and rewarding aspect of translating your studies into real self-improvement. You should be clear about how you want the program to benefit you. This involves setting clear study objectives in relation to the content of the course in terms of understanding, concepts, completing research or reviewing activities and relating the content of the modules to your own situation. Your objectives may understandably change as you work through the program, in which case you should enter the revised objectives on your study plan so that you have a permanent reminder of what you are trying to achieve, when and why.

Distance-learning check-list

Prepare your study environment, your study tools and rules.

Undertake detailed self-assessment in terms of your ability as a learner.

Create a format for your study plan.

Consider your study objectives and tasks.

Create a study forecast.

Assess your study performance.

Re-evaluate your study forecast.

Be consistent when managing your study plan.

Use your Appleton Greene Certified Learning Provider (CLP) for tutorial support.

Make sure you keep in touch with those around you.

Tutorial Support

Programs

Appleton Greene uses standard and bespoke corporate training programs as vessels to transfer business process improvement knowledge into the heart of our clients’ organizations. Each individual program focuses upon the implementation of a specific business process, which enables clients to easily quantify their return on investment. There are hundreds of established Appleton Greene corporate training products now available to clients within customer services, e-business, finance, globalization, human resources, information technology, legal, management, marketing and production. It does not matter whether a client’s employees are located within one office, or an unlimited number of international offices, we can still bring them together to learn and implement specific business processes collectively. Our approach to global localization enables us to provide clients with a truly international service with that all important personal touch. Appleton Greene corporate training programs can be provided virtually or locally and they are all unique in that they individually focus upon a specific business function. They are implemented over a sustainable period of time and professional support is consistently provided by qualified learning providers and specialist consultants.

Support available

You will have a designated Certified Learning Provider (CLP) and an Accredited Consultant and we encourage you to communicate with them as much as possible. In all cases tutorial support is provided online because we can then keep a record of all communications to ensure that tutorial support remains consistent. You would also be forwarding your work to the tutorial support unit for evaluation and assessment. You will receive individual feedback on all of the work that you undertake on a one-to-one basis, together with specific recommendations for anything that may need to be changed in order to achieve a pass with merit or a pass with distinction and you then have as many opportunities as you may need to re-submit project studies until they meet with the required standard. Consequently the only reason that you should really fail (CLP) is if you do not do the work. It makes no difference to us whether a student takes 12 months or 18 months to complete the program, what matters is that in all cases the same quality standard will have been achieved.

Support Process