Operational Excellence – Workshop 1 (Program Charter)

The Appleton Greene Corporate Training Program (CTP) for Operational Excellence is provided by Mr. Muenzing Certified Learning Provider (CLP). Program Specifications: Monthly cost USD$2,500.00; Monthly Workshops 6 hours; Monthly Support 4 hours; Program Duration 12 months; Program orders subject to ongoing availability.

If you would like to view the Client Information Hub (CIH) for this program, please Click Here

Learning Provider Profile

Meet Mr. Muenzing: Visionary Leader in Lean Transformation and Turnaround Management

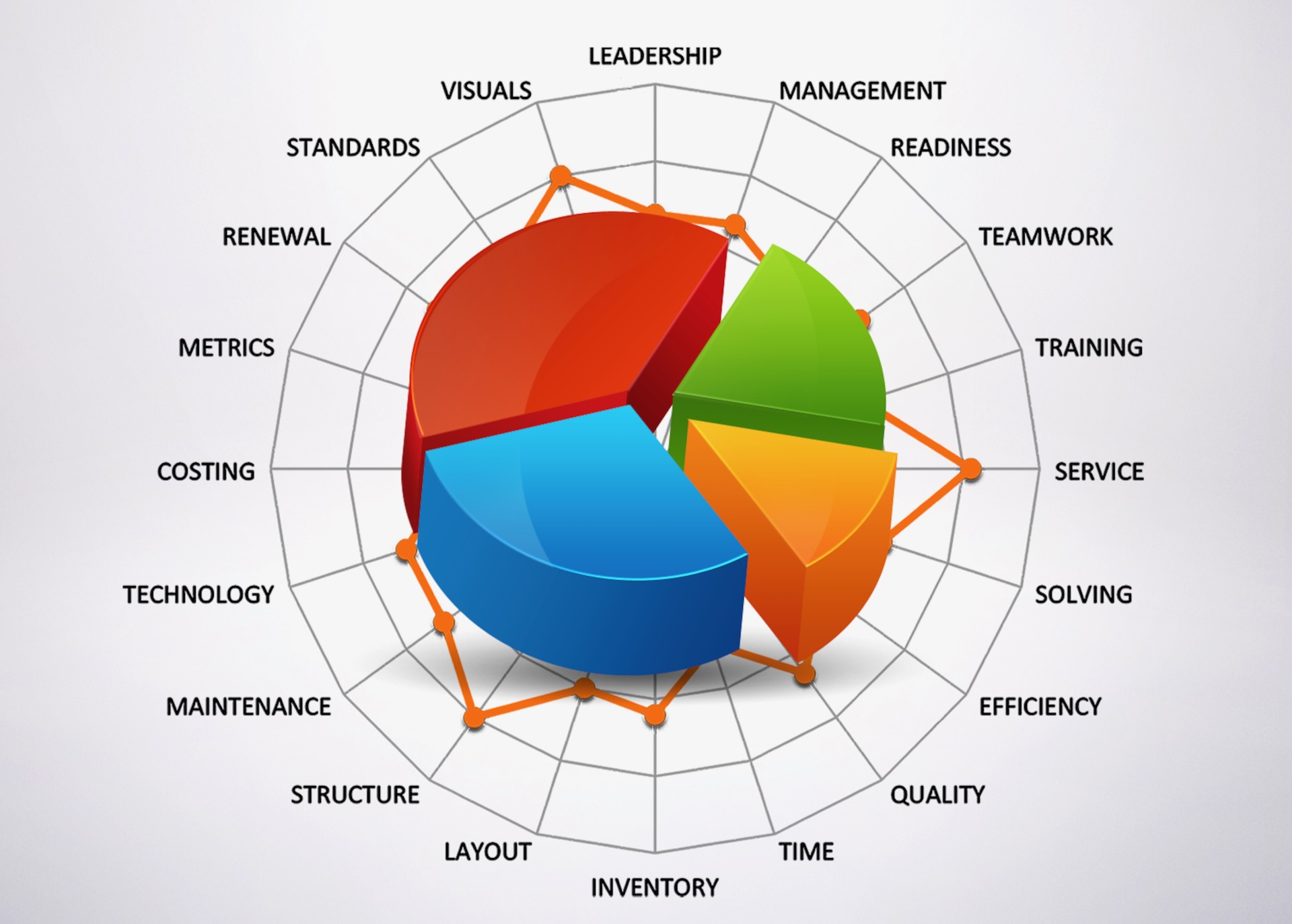

Mr. Muenzing is a distinguished authority in lean transformation and turnaround management, amassing three decades of executive and advisory roles in management consulting. As President of Leanmap, a specialized management consulting boutique, he empowers manufacturing, technology, and service enterprises to elevate performance and gain sustainable competitive advantages through world-class operations.

Driven by innovation and systems thinking, he earned a Bachelor’s in Electrical Engineering (BSEE) from FHD in Germany. He swiftly excelled in the Telecom industry, pioneering three groundbreaking innovations for base stations that showcased his visionary mindset and exceptional problem-solving skills. Recognizing the need for business acumen, he pursued a Master’s in Business Administration (MBA) from NSU in the USA, laying the foundation for his transformative leadership.

Throughout his illustrious career, he revitalized struggling companies and enhanced successful ones to reach world-class status. With extensive expertise in operations, product development, and business consulting, he offers diverse insights to clients. An accomplished author, he penned “The 20 Keys to World-Class Operations” and “From Chaos to Control.” He also shares his knowledge through speaking engagements on innovation, lean transformation, cost reduction, and quality excellence.

Mr. Muenzing’s expertise has been sought by over 150 client-organizations across 40 countries, driving operations toward world-class benchmarks. These transformations yielded financial benefits surpassing $500 million from top-10 programs, with an average return on investment (ROI) of 12x across all initiatives. With a remarkable 96% repeat clientele rate, his enduring impact is evident, leaving a lasting impression on clients. Key engagements include:

1. Leading Automotive Supplier (Sweden):

As an Industrialization Expert, led the Engineering team to enhance time-to-market (TTM), quality and delivery performance to major automotive customers. His systematic improvements in technology readiness and process capability led to a doubling of launch successes at the start of production (SOP) and an astounding 8x reduction in defects per unit (DPU) in just six months.

2. Major Semiconductor Fab (USA):

In the role of Operations Expert, spearheaded a transformation initiative to optimize cost-per-move (CPM) through adaptive maintenance, systematic problem analysis, and disciplined root-cause elimination. Coached 10 Advanced Module Engineering (AME) teams during the transition phase, realizing 326 projects that delivered $118 million cost savings (run rate) in the first year.

3. Pharmaceutical Operation (France):

As Operations Expert, led the factory turnaround with focus on operational efficiency (OEE) to ensure stable patient supply. As a result, doubled efficiency within 12 months, increased throughput 32% without spending capital, cleared backlog, reduced deviations by 25%, and shortened lead time by nearly 50%, while maturating the site towards Operational Excellence.

4. Largest Marine Electronics Company (Mexico):

As the Interim Operations Executive, he orchestrated a Manufacturing Turnaround that doubled throughput to meet customer demand. Through systematic defect reduction, design for manufacturability (DFM), and strict flow management, he achieved a 44% reduction in labor hours, 53% reduction in footprint, 94% reduction in inventory, and 66% reduction in rework in just one year.

5. Leading Flavor and Fragrance Company (Switzerland):

In the capacity of Global Leader for Lean and Operational Excellence, he spearheaded a Lean Transformation Initiative across 20 global flavor-production facilities. His efforts yielded over 400 improvement ventures, adding CHF 36 million to the company’s profits in just 3 years, while attaining a competitive edge by elevating both quality and delivery standards..

6. Largest Appliance Factory (China):

As the Integration Manager, he successfully merged two large assembly plants in Guangdong into one. Through streamlining material flow, balancing workload, and right-sizing manning, he reduced shortages and late deliveries by 50%, lowered on-hand inventories from 46 to 18 days, and added $20 million annual manufacturing capacity to meet forecasted demand.

Mr. Muenzing exemplifies impactful leadership through visionary expertise, driving lasting transformations by fostering world-class quality, speed, and efficiency. His consistent record of sustainable bottom-line growth and unwavering commitment to continuous improvement mark him as a global driving force behind corporate success. For anyone seeking to navigate their way to operational excellence, Mr. Muenzing is the expert to turn to. With his visionary leadership, profound expertise, and exceptional ability to create lasting improvements, he continues to shape the future of organizations across the globe.

MOST Analysis

Mission Statement

Unlock the OpEx Potential

Prepare for a transformative journey toward operational excellence. As with any improvement program, establishing a clear structure is essential to overcoming challenges and effectively capitalizing on opportunities. Without a clearly defined program charter, initiatives can easily lose direction, encounter scope creep and resource cannibalization, lead to misunderstandings, and ultimately fail to achieve their objectives. Recognizing the significance of a solid program charter establishes the foundation for a successful program launch and marks the beginning of our journey.

In this inaugural training module, you will gain valuable insights and practical strategies to drive your organization towards operational excellence. Discover the driving force behind pursuing excellence, craft a compelling vision statement, and develop a persuasive business case to secure the necessary support and resources. Build a dynamic core team, establish a precise target timeline, and foster a stimulating environment that encourages collaboration and innovation. Learn effective strategies to overcome barriers and implement an efficient control system to track progress and sustain achievements, while paving the way for performance breakthroughs and a culture of continuous improvement.

Upon completion of this inaugural training, you will emerge with a clear understanding of the critical role a charter plays in program success. Armed with the tools and techniques acquired during the workshop, you will confidently create and present a well-crafted program charter to key stakeholders, ensuring alignment and support from the start. By establishing a solid foundation, the program is better equipped to avoid potential pitfalls, mitigate risks, and maintain focus on delivering successful outcomes. Ultimately, the training empowers participants like you to become more effective leaders who can drive initiatives forward, foster collaboration, and inspire teams to achieve extraordinary results.

Objectives

01. Driving Force: Identify key reasons for the program, creating purpose and commitment.

02. Vision Statement: Outline desired future state, providing direction for the program.

03. Anticipated Gains: Forecast program benefits and align with organizational objectives.

04. Required Resources: Identify necessary resources, including people, capital, information.

05. Business Case: Justify the program based on its financial, operational, strategic benefits.

06. Core Team: Build team for driving progress, monitoring milestones, addressing challenges.

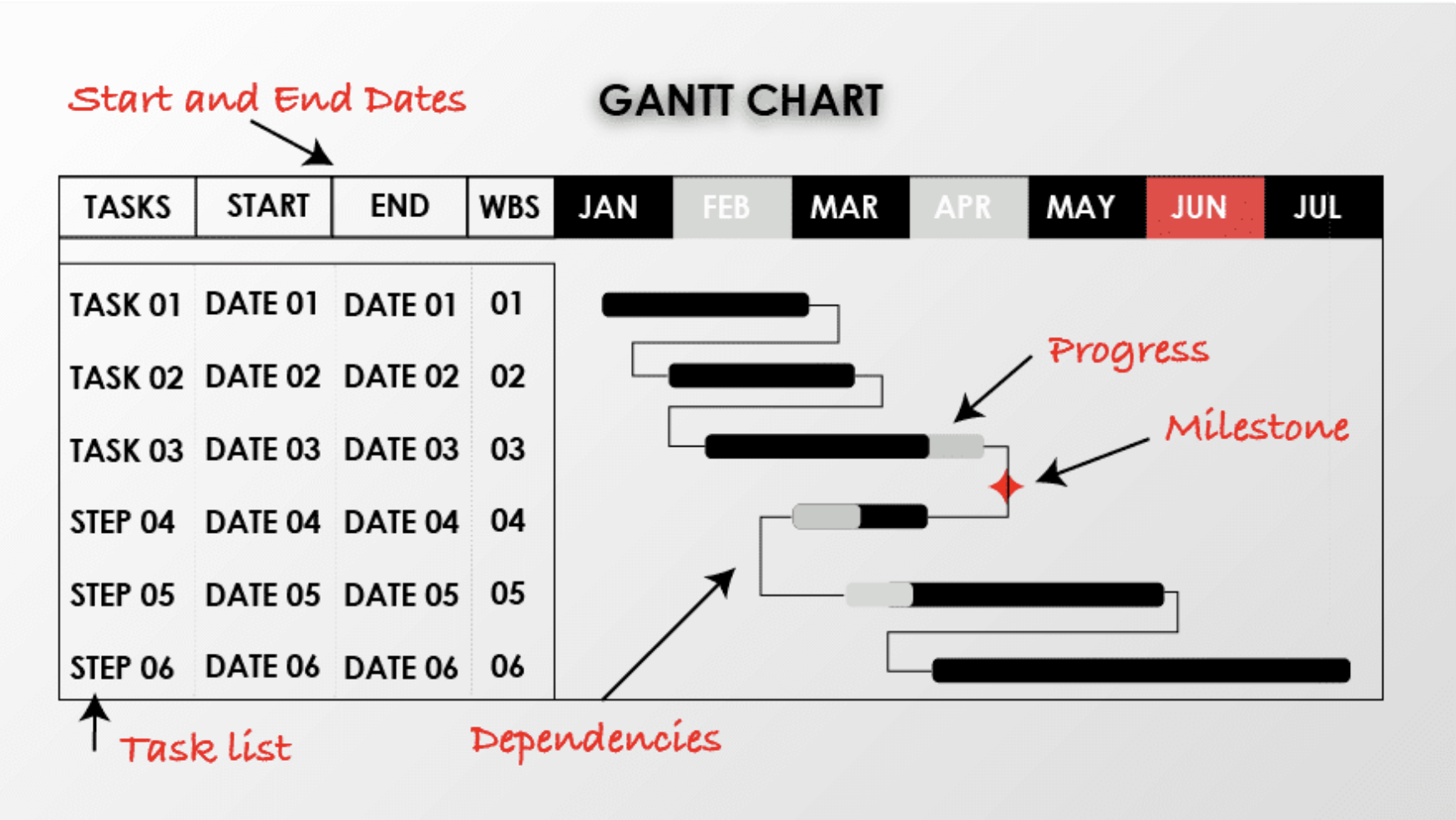

07. Target Timeline: Define program milestones for tracking progress and accountability.

08. Basic Skills: Provide initial training with focus on teams, techniques, and closing knowledge gaps.

09. Stimulus Plan: Implement incentives that motivate people to act, fostering positive environment.

10. Change Story: Engage people with compelling narrative, communicate benefits, inspire participation.

11. Barrier Removal: Identify and overcome obstacles hindering progress, proactively mitigate challenges.

12. Control System: Establish the management infrastructure to seamlessly plan and execute the program.

Strategies

01. Driving Force: The first step involves identifying and emphasizing the key reasons behind the OpEx program. It focuses on creating a strong sense of purpose and commitment among stakeholders to drive the desired change.

02. Vision Statement: A vision statement outlines the desired future state that the OpEx program aims to achieve. It provides a clear direction and serves as a guiding principle for decision-making and goal-setting throughout the implementation phase.

03. Anticipated Gains: Identify the benefits from the OpEx program, such as cost reduction, operational efficiency, customer satisfaction, market expansion, or quality boost to foster enthusiasm and support among stakeholders for active participation.

04. Required Resources: Assess and secure necessary resources, including finances, technology, and personnel to successfully implement the OpEx program and ensure fully impact.

05. Business Case: The business case articulates the rationale and benefits of the OpEx program from a financial, operational, and strategic perspective. It highlights the expected value-add and helps justify the allocation of resources and support for the program.

06. Core Team: Executing the OpEx program requires a dedicated team of individuals with relevant expertise and authority – the program sponsor, manager, controller, specialists, influencers – who collaborate closely to drive progress and address challenges.

07. Target Timeline: Developing a well-defined timeline with specific milestones and deadlines is essential for tracking progress and maintaining accountability. The target timeline provides a reference for implementing the OpEx program.

08. Basic Skills: Providing initial training to ensure people have the knowledge and skills to fully participate. It focuses on teams, tools, and techniques to identify existing capabilities and also the gaps to be closed during the OpEx program.

09. Stimulus Plan: A stimulus plan involves designing and implementing incentives, rewards, or recognition mechanisms to encourage people to act. It aims to foster a positive environment that reinforces desired behaviors and outcomes in pursuit of OpEx.

10. Change Story: Crafting a compelling narrative around the OpEx mission helps engage stakeholders and create a shared view of the need for change. It communicates the benefits, inspiring individuals to embrace and actively participate in the process.

11. Barrier Removal: Identifying and overcoming potential obstacles that may hinder progress is vital for successful implementation. It involves proactively mitigating challenges associated with resources, processes, capabilities, and mindsets to ensure progress.

12. Control System: By setting up a management infrastructure, the team gains the capacity to flawlessly strategize, execute, monitor, and control program activities, fostering the fulfillment of the mission and the attainment of the intended impact.

Tasks

01. Create a task on your calendar to complete within 30 days the Driving Force.

02. Create a task on your calendar to complete within 30 days the Vision Statement.

03. Create a task on your calendar to complete within 30 days the Anticipated Gains.

04. Create a task on your calendar to complete within 30 days the Required Resources.

05. Create a task on your calendar to complete within 30 days the Business Case.

06. Create a task on your calendar to complete within 30 days the Core Team.

07. Create a task on your calendar to complete within 30 days the Target Timeline.

08. Create a task on your calendar to complete within 30 days the Basic Skills.

09. Create a task on your calendar to complete within 30 days the Stimulus Plan.

10. Create a task on your calendar to complete within 30 days the Change Story.

11. Create a task on your calendar to complete within 30 days the Barrier Removal.

12. Create a task on your calendar to complete within 30 days the Control System.

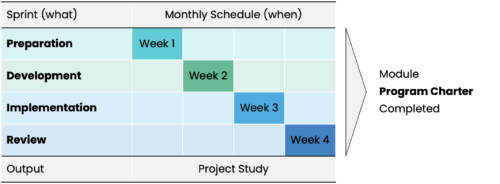

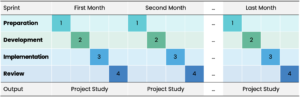

The OpEx program operates on a structured schedule with monthly modules to achieve operational excellence. These modules are divided into four sprints: (1) Preparation and study of the material, (2) Development of new capabilities in the workshop, (3) Implementation of the new capabilities and findings, (4) Review of effectiveness and documentation of results in the project study. This regular rhythm facilitates efficient planning and has been remarkably successful in maintaining progress. The 12 tasks refer to the implementation and documentation of the 12 elements by each participant in their respective areas of responsibility.

Introduction

The OpEx program operates on a structured schedule with monthly modules to deliver operational excellence. These modules are further segmented into four sprints: Preparation, Development, Implementation, Review. In the upcoming sections, we will discuss the roles of each sprint in delivering the project study about the “Program Charter”.

Preparation

Prior to the Workshop: Define Participants and Mission

To ensure a successful launch of the OpEx program, we will need to define the initial mission, invite key participants from various departments, assess the current state, clarify the purpose and scope, identify guiding values and principles, and craft a clear mission statement with breakthrough objectives. By addressing these aspects, we lay a strong foundation for our journey towards operational excellence.

1. Invite Participants:

When planning an OpEx program, invite functional heads from various departments to ensure a comprehensive approach. Key participants include the heads of Commercial, Manufacturing, Service, Engineering, Logistics, Finance, Maintenance and Facilities, Human Resources, Information Technology, Quality Assurance, and General Management. Their involvement ensures alignment with commercial objectives, optimization of manufacturing processes, improvement of service delivery, innovation in engineering, efficiency in logistics operations, financial goal alignment, maintenance and facility optimization, employee engagement, information availability, quality control, and strategic guidance. By including these participants, the OpEx program benefits from their expertise, insights, and organizational influence, leading to a holistic implementation of operational excellence initiatives.

2. Assess the Current State:

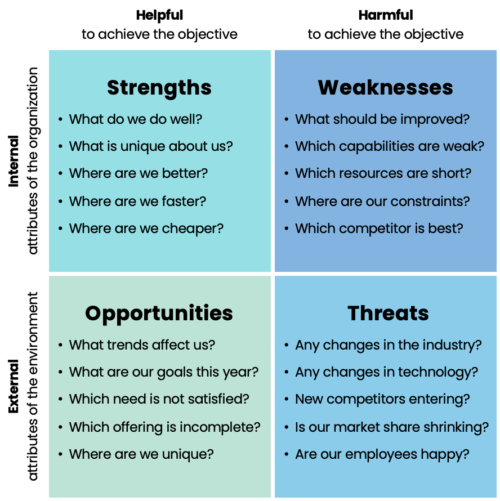

Before crafting a mission statement, define what works and what does not. Conduct a SWOT analysis to evaluate the operation’s strengths, weaknesses, opportunities, and threats. Identify areas where the operation excels and areas that need improvement. Consider potential challenges arising from new technologies, market needs, competition, or unresolved issues. This analysis helps pinpoint areas for enhancement and challenges to address.

3. Define Purpose and Scope:

Clarify the specific goals the OpEx program aims to achieve, such as improving efficiency, quality, or customer satisfaction. Establish key performance indicators (KPIs) to measure program success, such as cycle time reduction or defect rate improvement. Define the purpose and scope with a focus on the desired outcomes and measurable results.

4. Identify Guiding Values and Principles:

Identify core values held by the organization, such as integrity, accountability, or innovation, along with principles that guide the program, such as continuous improvement, data-driven decision making, or customer focus. Ensure alignment between the OpEx program and the organization’s culture and values. Emphasize the importance of transparency, ethics, and the principles driving decision-making.

5. Craft the Mission and Breakthrough Objectives:

Based on the current state assessment, purpose and scope, and guiding values and principles, develop a clear and concise OpEx mission statement. Capture the essence of the program’s purpose, objectives, and values in a single sentence. Support the mission statement with facts and figures to provide a solid foundation. For example, “To optimize operational processes and drive continuous improvement, delivering exceptional value to customers and stakeholders.”

Conclusion:

The “Program Charter” workshop marks the beginning of our pursuit of operational excellence. Through meticulous preparation, including defining our mission, inviting key participants, assessing the current state, clarifying purpose and scope, and identifying guiding values, we set ourselves up for success. This workshop sets the stage for collaboration, aligning efforts, and driving a culture of continuous improvement. Together, we will optimize processes, enhance customer satisfaction, and achieve exceptional results in our journey towards operational excellence.

Development

During the Workshop: Define the Framework

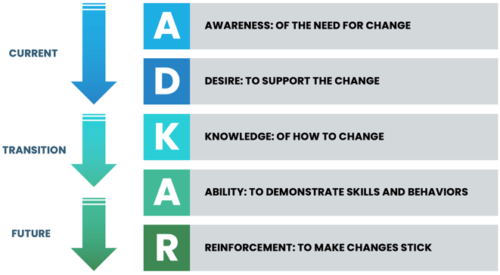

Effective change management is essential to successful operational excellence initiatives. We will now explore how the ADKAR model to create Awareness, Desire, Knowledge, Ability, Reinforcement. This proven change management framework supports leaders in facilitating a smooth transition, from current to future state. By including examples at each step of the ADKAR process, we can address key questions participants have and ensure their active engagement and commitment to the OpEx program.

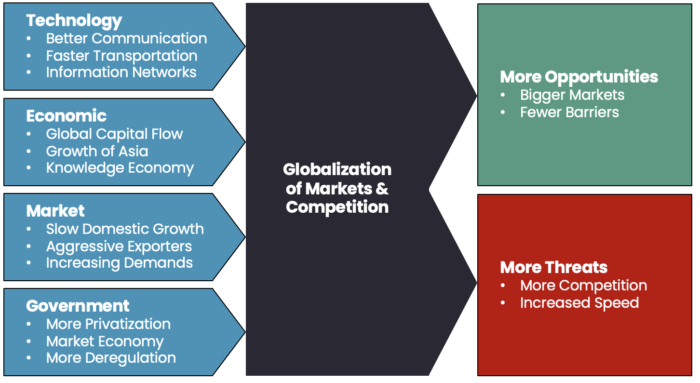

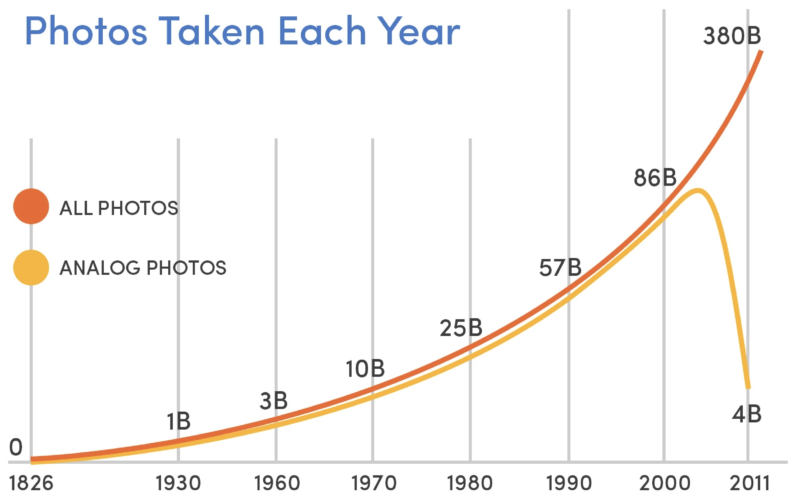

Awareness: Why should I care?

To create awareness, present compelling information about the current state and the challenges that necessitate change. For instance, illustrate how outdated processes are hindering productivity by showcasing data and case studies. Engage participants in open discussions to foster a shared understanding of the change’s purpose and benefits, allowing them to see the relevance and urgency of the transformation. Or share a visual representation of the organization’s declining market share and explain how embracing OpEx can help regain competitiveness.

Desire: What is in for me?

Generate desire for change by showcasing a compelling vision of the desired outcome. Share success stories from individuals or teams who have experienced positive results through similar changes. Invite a team member who achieved remarkable improvements in their workflow efficiency to share their experience and the positive impact it had on their career growth and work-life balance. Help participants connect emotionally by discussing how OpEx aligns with their personal and professional aspirations, growth opportunities, and job satisfaction.

Knowledge: What do I need to know?

Impart knowledge about the change by providing targeted training sessions. Use interactive activities and simulations to ensure active learning. Share relevant documentation, tutorials, and resources that serve as references and learning materials. Conduct a hands-on workshop where participants can practice using new software tools that streamline operational processes. Encourage open discussions to address participants’ questions and enhance their understanding of the change.

Ability: What do I need to develop?

Develop participants’ ability to implement the change successfully. Offer opportunities for practice through role-plays, group activities, or real-life scenarios. Facilitate a role-play exercise where participants practice addressing resistance to change from a respected team leader. Assign mentors or coaches who can guide participants and provide feedback. Foster a collaborative environment where participants can share experiences and best practices, building confidence and enhancing their skills.

Reinforcement: What do I need to change?

Reinforce the change mindset by defining strategies that recognize and reward desired behaviors. Share examples of how other organizations successfully reinforced change through performance recognition programs, continuous feedback loops, or celebratory events. Highlight how a company celebrated teams that achieved significant process improvements and the positive impact it had on employee morale and motivation. Emphasize the importance of ongoing communication, feedback channels, and supportive systems.

Ready for Change!

By following the ADKAR framework, we have designed an agenda that addresses participants’ key needs during the OpEx transformation. Through creating awareness, instilling desire, imparting knowledge, developing abilities, and reinforcing the change mindset, participants are equipped with the right mindset and skills for success. This workshop serves as a catalyst for embracing change, connecting it to personal aspirations, and fostering collaboration, learning, and support. Together, we empower participants to navigate the OpEx journey and drive it forward with confidence.

Implementation

After the Workshop: Implement the Program Charter

After the initial OpEx workshop, the focus shifts to applying the workshop insights and translating them into a concrete program charter. This involves collaborative exercises and active engagement to foster participation, diverse perspectives, and unwavering commitment. Key steps include aligning stakeholders, crafting a compelling vision, anticipating gains, devising a resourcing plan, and constructing a persuasive business case. These elements form a solid foundation for tangible outcomes. Establishing a dedicated core team, defining a target timeline, and developing essential skills ensure steady progress in our pursuit of excellence. Supported by a robust program management infrastructure, this comprehensive program charter sets the stage for a successful OpEx kick-off.

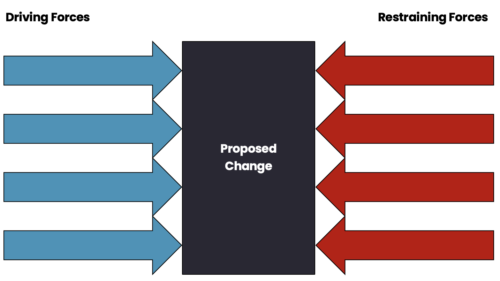

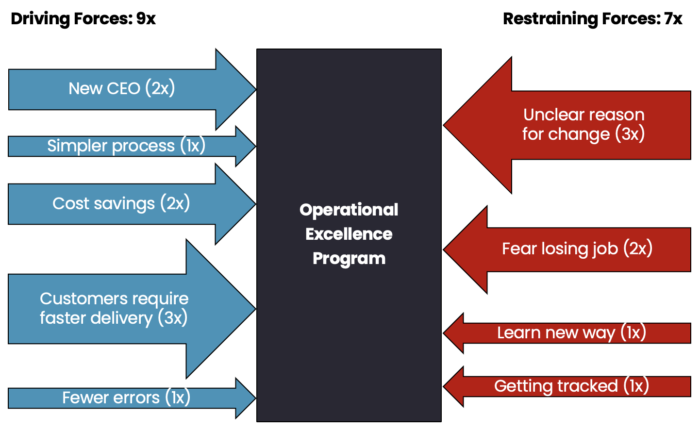

1. Driving Force:

• Brainstorm the key reasons for pursuing excellence from the perspective of stakeholders.

• Identify the potential risks of inaction and the costs associated with maintaining the status quo.

• Identify the potential benefits of achieving excellence, gains in speed, quality, productivity.

2. Vision Statement:

• Collaboratively define the desired future state by creating a visual representation of the dream state.

• Create a clear and concise vision statement that inspires people to work towards that goal.

• Communicate the vision to ensure alignment and understanding of the organization’s direction.

3. Anticipated Gains:

• Choose key performance metric to improve, such as cost, speed, quality, and efficiency.

• Calculate or estimate potential gains by bridging the gap between current and desired states.

• Present and discuss anticipated gains to align stakeholder expectations and garner support.

4. Required Resources:

• Identify necessary human resources to develop, deploy and contribute to the program.

• Identify financial resources, the capital and funding required to implement the program.

• Identify technological resources, including hardware, software, and technological infrastructure.

5. Business Case:

• Analyze the financial, operational, and strategic benefits and value of the program.

• Compile data to support the case, such as financial projections, benchmarking analysis, and market study.

• Develop a persuasive business case document with clear arguments, visuals, and concrete examples.

6. Core Team:

• Identify individuals with relevant expertise and authority to form the core team.

• Assign roles and responsibilities for program sponsor, manager, controller, specialists, and staff.

• Schedule weekly team meetings to foster collaboration, track progress, and address challenges.

7. Target Timeline:

• Develop a detailed timeline with specific deadlines and deliverables for each milestone.

• Establish a tracking mechanism to monitor progress against the target timeline.

• Communicate the program plan to stakeholders to ensure clarity and accountability.

8. Basic Skills:

• Conduct a skills assessment and determine the extent of training needed to fill any gaps.

• Provide introductory training, reference guides for continuous learning and skill development.

• Schedule coaching sessions to resolve doubts and incompetence, physical and mental obstacles.

9. Stimulus Plan:

• Identify the desired behaviors and outcomes that must rewarded to encourage participation.

• Define performance metrics to measure the contributions of teams and individuals.

• Design an incentive scheme that includes rewards, recognition, and performance bonuses.

10. Change Story:

• Craft a compelling narrative that clearly articulates the need for change and the benefits it will bring.

• Develop presentations and videos that effectively convey the change story to different audiences.

• Conduct targeted communication campaigns to reach all stakeholders via meetings, mailings, posts.

11. Barrier Removal:

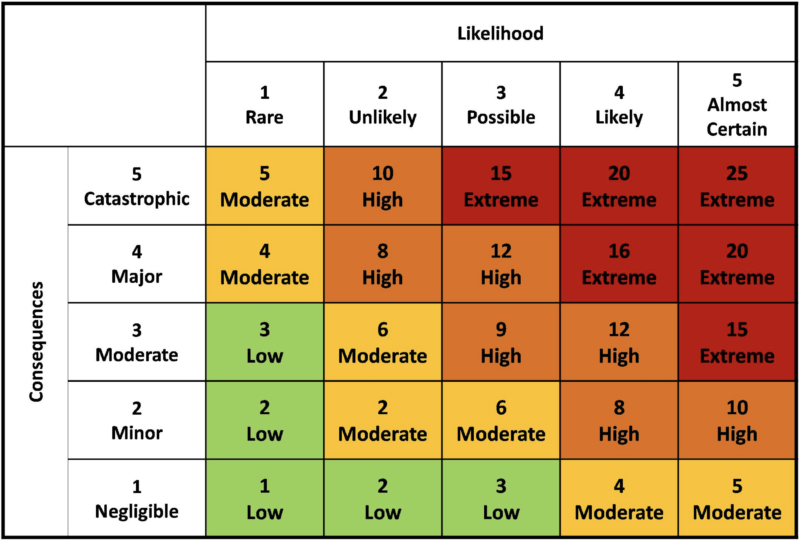

• Conduct a risk analysis to identify potential barriers and challenges that may hinder progress.

• Develop mitigation strategies and contingency plans to proactively address identified barriers.

• Establish a steering committee to involve leaders in finding solutions to overcome obstacles.

12. Control System:

• Develop the program scorecard to track progress and evaluate impact on people and business.

• Define the management matrix with clear roles, responsibilities, and expectations for each stakeholder.

• Define the governance structure and establish the program management office (PMO).

Conclusion:

Through the development and implementation of the program charter, we have established a solid foundation for our OpEx journey. The extensive preparation involved in aligning stakeholders, creating an inspiring vision, and building a persuasive business case has set the stage for success. With a committed core team, a well-defined target timeline, and essential skills in place, we have a strong foundation for progress. Furthermore, by implementing a stimulus plan, sharing a compelling change story, and proactively addressing barriers, we foster engagement and overcome obstacles that may arise along the way. Finally, the establishment of a robust program management infrastructure ensures effective monitoring and long-term impact. Together, these elements guarantee a successful launch of our OpEx program and pave the way for achieving operational excellence.

Review

After the Implementation: Reviewing Effectiveness

The post-implementation review plays a vital role in assessing the understanding of participants and the robustness of the OpEx program charter. By conducting a thorough evaluation of the charter, the review ensures that all key aspects of the program have been effectively defined, aligned, and communicated. It serves as a critical checkpoint to assess whether the driving force behind pursuing excellence, the vision statement, and the business case have been well understood and embraced. Furthermore, the review evaluates the commitment of individuals and teams, the availability of necessary resources, and the alignment of the program roadmap with the target timeline. By conducting this review, organizations can identify any gaps or areas for improvement in the program charter, allowing for necessary adjustments and ensuring a strong foundation for a success launch of the OpEx program.

1. Mission Checkpoint:

At the Mission Checkpoint, the review focuses on assessing whether the driving force behind pursuing excellence has been effectively articulated and understood by stakeholders. It involves evaluating the brainstormed key reasons for pursuing excellence and determining if they have been clearly communicated in the charter. Additionally, the review should assess if the potential risks of inaction and costs associated with maintaining the status quo have been identified and highlighted. Furthermore, it should evaluate whether the potential benefits of achieving excellence, including gains in speed, quality, and productivity, have been quantified and communicated.

2. Readiness Checkpoint:

The Readiness Checkpoint aims to evaluate the readiness of the organization to embark on the OpEx program. It involves assessing whether the vision statement has been collaboratively defined, visually represented, and effectively communicated to inspire people to work towards the desired future state. The review should also examine whether the chosen key performance metrics to improve, such as cost, speed, quality, and efficiency, have been clearly identified. Additionally, it should assess whether the calculations or estimates of potential gains adequately bridge the gap between the current and desired states. This checkpoint also involves evaluating the presentation and discussion of anticipated gains to ensure stakeholder alignment and support.

3. Commitment Checkpoint:

The Commitment Checkpoint focuses on assessing the level of commitment from individuals and teams involved in the OpEx program. It involves evaluating whether the necessary human resources with relevant expertise and authority have been identified and assigned roles and responsibilities. The review should assess if regular team meetings have been scheduled to foster collaboration, track progress, and address challenges. Furthermore, it should determine if a skills assessment has been conducted to identify any training needs and if efforts have been made to provide training, reference guides, and coaching sessions to support skill development. This checkpoint also includes reviewing the stimulus plan and assessing whether desired behaviors and outcomes have been defined and if an incentive scheme has been designed to encourage participation and reward performance.

4. Resourcing Checkpoint:

The Resourcing Checkpoint focuses on assessing whether the OpEx program has been adequately resourced. It involves evaluating whether the necessary financial resources, including capital and funding requirements, have been identified and addressed in the charter. The review should assess if the technological resources, such as hardware, software, and infrastructure, have been identified and accounted for. Additionally, it should determine if a comprehensive business case has been developed, analyzing the financial, operational, and strategic benefits and value of the program. The review should also assess whether the business case includes supporting data such as financial projections, benchmarking analysis, and market studies.

5. Roadmap Checkpoint:

The Roadmap Checkpoint evaluates the effectiveness of the program roadmap and its alignment with the target timeline. The review should assess if a detailed timeline with specific deadlines and deliverables for each milestone has been developed. It should also determine if a tracking mechanism has been established to monitor progress against the target timeline. Furthermore, the review should evaluate the communication of the program plan to stakeholders to ensure clarity and accountability. This checkpoint also involves reviewing the barrier removal strategies and assessing if a risk analysis has been conducted, potential barriers have been identified, and mitigation strategies and contingency plans have been developed. It should also assess if a steering committee has been established to involve leaders in finding solutions to overcome obstacles.

Conclusion:

The implementation review, utilizing the five checkpoints outlined above, offers a structured approach to evaluate the effectiveness of the OpEx program charter, identify gaps, and highlight areas for improvement. By conducting a Yes/No assessment for each checkpoint, you can objectively gauge progress and determine the readiness level for launching OpEx. Each Yes response corresponds to a score of 20 points, and a flawless score of 100 points or 100% is attained when all five questions receive positive answers. It is crucial to adhere strictly to this evaluation process, maintaining honesty throughout. Repeat the review as necessary until the desired full score is achieved. This rigorous assessment ensures a robust program charter, laying the foundation for a successful OpEx launch.

Executive Summary

Chapter 1: Uncovering the Driving Force

Unleash the Power of Purpose:

In the absence of a clear driving force behind pursuing excellence, organizations can lack direction and motivation, everyone will be “fat and happy”. To achieve excellence, it is crucial to understand the driving force behind our pursuit. In this module, we will uncover the core motivations and reasons for pursuing excellence. By identifying the driving force, we gain a deeper understanding of the purpose behind our efforts. This understanding enables us to align our actions, inspire our teams, and unlock the potential for remarkable gains in speed, quality, and productivity.

Chapter 2: Creating a Compelling Vision Statement

Inspire and Unify:

Without a clear and concise vision statement, the desired future state will be unclear, resulting in misguided actions and false starts. A compelling vision statement serves as a guiding light that inspires and unifies the entire organization. In this module, we will collaboratively define a vision for the future, engaging key stakeholders in the process. By creating a compelling vision statement, we foster alignment and inspire individuals at all levels to work towards a common goal. This shared vision serves as a compass, directing our efforts and empowering everyone to contribute to the realization of our organizational aspirations.

Chapter 3: Exploring the Anticipated Gains

Identify Opportunities and Advantages:

Understanding and anticipated gains of the OpEx program is essential for effective decision-making and resource allocation. In this module, we will analyze the financial, operational, and strategic advantages that the program can bring. By identifying and quantifying the potential benefits, we gain a clear understanding of the opportunities that lie ahead. This knowledge enables us to prioritize initiatives and secure the necessary support and resources for the program’s success.

Chapter 4: Securing Required Resources

Mobilize Support and Allocation:

To implement the OpEx program successfully, we need to identify and secure the required resources. In this module, we will assess the human, financial, and technological resources necessary for the program’s execution. By understanding the resource requirements, we can mobilize support, allocate budgets, and ensure that the necessary tools and capabilities are in place. This enables us to execute the program effectively and maximize the chances of achieving the desired outcomes.

Chapter 5: Developing a Persuasive Business Case

Justify the Program’s Value:

A persuasive business case is crucial for gaining buy-in and support from stakeholders. In this module, we will build a robust business case by presenting the expected benefits and required resources in a compelling manner. By clearly articulating the value proposition, we can demonstrate the program’s potential return on investment and its alignment with the organization’s strategic objectives. A strong business case increases the likelihood of obtaining the necessary approvals and resources, paving the way for successful implementation.

Chapter 6: Forming the Core Team

Empower Collaboration and Expertise:

Without a capable and coordinated team, the success of the OpEx program can be at risk. In this module, we will form a core team by identifying individuals with relevant expertise and assigning key roles and responsibilities. By forming a strong core team, we establish a foundation for effective collaboration, expertise sharing, and decision-making. This empowers our organization to navigate the challenges ahead with confidence, ensuring that the OpEx program is implemented successfully and efficiently.

Chapter 7: Setting the Target Timeline

Navigate with Precision:

The absence of a structured timeline and accountability can lead to false starts and costly course corrections. A well-defined target timeline is crucial to ensure efficient program management. In this module, we will develop a detailed timeline with specific deadlines and deliverables for each milestone. By establishing a target timeline, we provide clarity and direction, enabling us to track progress effectively and manage resources efficiently. This ensures that we remain on track and achieve our OpEx objectives within the defined timeframes.

Chapter 8: Building Basic Skills

Strengthen the Foundation:

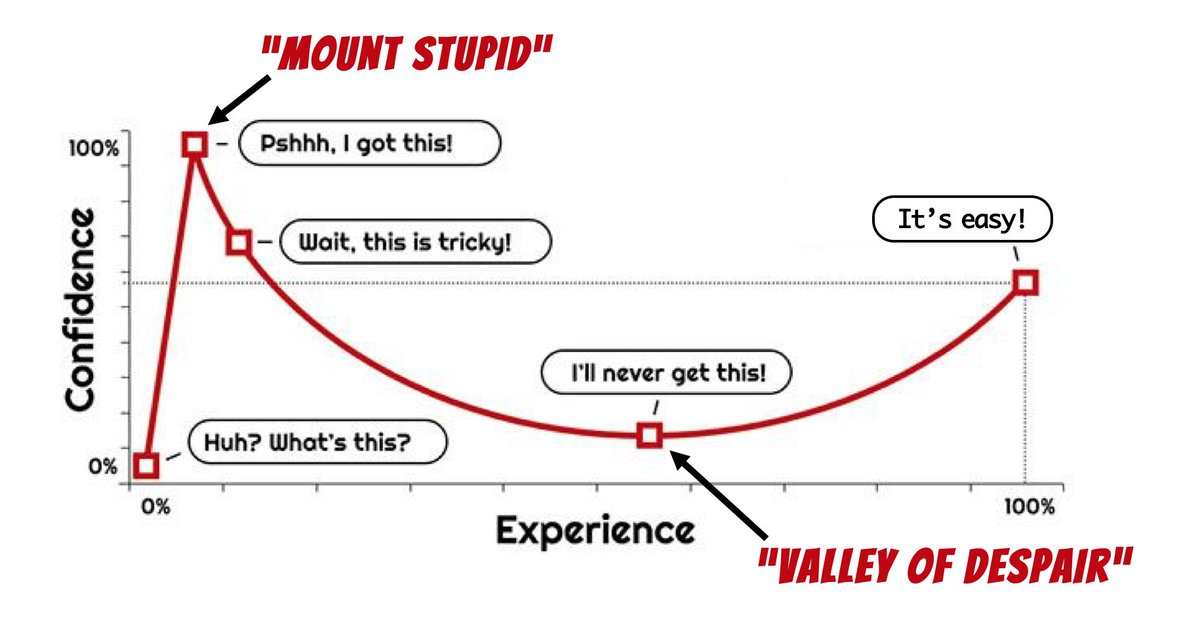

When individuals lack essential skills, their anxiety can hinder their contribution to the OpEx program. In this module, we will conduct a skills assessment and provide necessary training and coaching to enhance individual and team capabilities. By strengthening the basic skills of our workforce, we equip them with the knowledge and tools needed to drive operational excellence. This empowers individuals to overcome challenges, adapt to change, and deliver exceptional results, thus elevating overall organizational performance.

Chapter 9: Promoting the Stimulus Plan

Cultivate Motivation and Performance:

Without a well-designed stimulus plan, motivation and engagement will suffer, slowing the program down. In this module, we will develop a stimulus plan that identifies desired behaviors and outcomes, along with performance metrics to measure progress and contributions. By fostering a stimulus plan, we create an environment that motivates and engages individuals and teams. The plan, including rewards, recognition, and performance bonuses, incentivizes excellence and cultivates a high-performance culture, leading to improved productivity, employee satisfaction, and overall organizational success.

Chapter 10: Crafting an Engaging Change Story

Communicate the Need for Transformation:

Change is inevitable, while resistance and lack of understanding will impede progress without a compelling change story. In this module, we will craft a compelling change story that clearly articulates the reasons for change and the benefits it will bring. By crafting an engaging change story, we inspire and rally stakeholders behind the OpEx program. Through impactful communication campaigns, presentations, and targeted messaging, we create awareness, understanding, and enthusiasm for the transformational journey, facilitating smoother adoption and implementation.

Chapter 11: Proactively Removing Barriers

Foster Problem Solving and Continuous Improvement:

Potential barriers and challenges will hinder the progress of the OpEx program if not addressed proactively. In this module, we will proactively identify and analyze risks, develop mitigation strategies, and establish a steering committee to foster problem-solving and continuous improvement. By proactively removing barriers, we create a culture of resilience and agility. The ability to anticipate and address obstacles enables us to navigate challenges efficiently, minimizing disruptions and maximizing progress towards our OpEx goals.

Chapter 12: Implementing an Effective Control System

Track, Evaluate, Sustain Success:

Without an effective control system, the organization will likely struggle to track progress and evaluate the impact of the OpEx program. An effective control system is essential for monitoring progress, evaluating impact, and sustaining improvements. In this module, we will develop a program scorecard and establish clear roles, responsibilities, and expectations for stakeholders. By implementing an effective control system, we gain valuable insights into the program’s performance, ensuring that we stay on course and make data-driven decisions. This fosters accountability, facilitates continuous improvement, and empowers us to achieve and sustain operational excellence over the long term.

Curriculum

Operational Excellence – Workshop 1 – Program Charter

- Driving Force

- Vision Statement

- Anticipated Gains

- Required Resources

- Business Case

- Core Team

- Target Timeline

- Basic Skills

- Stimulus Plan

- Change Story

- Barrier Removal

- Control System

Distance Learning

Introduction

Welcome to Appleton Greene and congratulations on enrolling in the Operational Excellence (OpEx) corporate training program. We are excited to have you on board. Throughout this program, you will engage in a unique distance-learning experience that combines academic knowledge with practical implementation. Our methods and materials have been carefully curated to ensure that you gain maximum benefits and enjoy the learning journey. We understand that distance learning may feel daunting if you haven’t experienced it before, so we have provided this guide to help you navigate the program effectively. Take some time to familiarize yourself with the guide and the resources available to you, and feel free to reach out to our tutorial support team for any assistance you may need. We believe this program will be both challenging and enjoyable, and we look forward to supporting you as you progress towards your goals.

Study environment

Creating a conducive study environment is essential for your learning journey. Find a quiet and private space, preferably a dedicated room where you can isolate yourself from external disturbances and distractions. Ensure the room is well-lit and creates a relaxed and pleasant ambiance. Treat yourself within this environment by incorporating elements like soft soothing background music, gentle lighting, workout equipment, a pleasant view if available, and a spacious desk with a comfortable chair. It’s important to communicate your study schedule and rules to your family, so they understand and respect your study time. If a separate study room is not possible, you’ll need to pay extra attention to developing and managing your study schedule to accommodate others. Remember, a well-designed study environment directly impacts your productivity and focus.

Study tools & rules

To optimize your study experience, it is important to have reliable and well-maintained study tools. In the spirit of operational excellence, ensure that your computer, scanner, and printer are in good working order and that you have internet access. Invest in a comfortable chair that provides adequate support and implement a filing system on your computer. It can be frustrating to waste valuable study time dealing with unreliable or inadequate tools. Keep your study tools up to date to enhance efficiency. Additionally, establish study rules for yourself to maintain discipline in terms of when and how you study. This distance-learning guide will assist you in defining these rules. It is also crucial to communicate and negotiate study rules with your family, friends, or anyone you live with, ensuring their understanding and support. Involving them as part of your study team can greatly contribute to your success in completing the program.

Successful distance-learning

As a distance-learner, you have the freedom to study at your own pace and in your preferred manner, but it is essential to take full responsibility for managing your study contribution. Being accustomed to self-management, adept at working independently, and skilled in managing others are advantageous qualities for distance-learners. It is crucial to remain mindful of the reasons and objectives behind your study efforts, using them as motivation when needed. Stay focused on your long-term goals and short-term objectives. Remember that there won’t be anyone to pamper or spoon-feed you information, so finding ways to self-encourage and appreciate your progress is important. Keep track of your study progress, ensuring that you recognize your achievements and regularly reassess your goals and objectives. By maintaining a strong sense of purpose and continuously evaluating your progress, you can maximize the benefits of your distance-learning experience in OpEx.

Self-assessment

Appleton Greene’s training programs – such as Operational Excellence (OpEx) – are designed for post-graduate learners, assuming that you have already obtained a business-related degree and possess prior learning experience. As an experienced learner, you should have a good understanding of your study preferences, strengths, and areas for improvement. Reflect on your personal learning style, such as whether you are most productive in the morning or evening and identify the study methods that resonate with you the most. Assess your consistency as a learner and the strategies you employ to maintain discipline and enjoyment during your studies. Self-awareness as a learner is crucial, and conducting a SWOT analysis on yourself can be beneficial. Identify your internal strengths and weaknesses as a student, along with external opportunities and threats. This analysis will inform the development of your study plan, enabling you to leverage your strengths, address your weaknesses, seize opportunities, and navigate potential challenges, maximizing your chances of success.

Accepting responsibility

Training programs require significant investment in terms of cost and time. As a student, the responsibility for successful completion rests solely on you, especially in distance-learning. Taking responsibility is crucial to completing your training program. It’s easy to blame others or external factors when things go wrong, but if it’s your failure, you have the power to act and make changes. Each student has unique study methods, and it’s important to find a personalized study plan that works for you. Ultimately, your success or failure depends on your own efforts and mindset, as Henry Ford famously said: “If you think you can, or you think you cannot – in both cases, you are right.”

Planning

By far the most critical contribution to stress, is the feeling of not being in control. In the absence of planning we tend to be reactive and can stumble from pillar to post in the hope that things will turn out fine in the end. Invariably they don’t! To be in control, we need to have firm ideas about how and when we want to do things. We also need to consider as many possible eventualities as we can, so that we are prepared for them when they happen. Prescriptive change is far easier to manage and control, than emergent change. The same is true with distance-learning. It is much easier and much more enjoyable, if you feel that you are in control and that things are going to plan. Even when things do go wrong, you are prepared for them and can act accordingly without any unnecessary stress. It is important therefore that you do take time to plan your studies properly.

Management

Once you have developed a clear study plan, it is of equal importance to ensure that you manage the implementation of it. Most of us usually enjoy planning, but it is often during implementation when things go wrong. Targets are not met, and we do not understand why. Sometimes we do not even know if targets are being met. It is not enough for us to conclude that the study plan just failed. If it is failing, you will need to understand what you can do about it. Similarly if your study plan is succeeding, it is still important to understand why, so that you can improve upon your success. You therefore need to have guidelines for self-assessment so that you can be consistent with performance improvement throughout the program. If you manage things correctly, then your performance should constantly improve throughout the program.

Study objectives

When developing your program objectives, start by prioritizing your reasons for undertaking the training program. Ensure your objectives are concise and avoid duplicating similar ideas. Create headings such as Customer, Company, Colleagues, Family, Self and Society, and brainstorm ideas under each heading. Rearrange these ideas in order of priority. Choose the top item from each heading as your program objectives, aiming for a maximum of five to maintain clear focus. It’s likely that achieving these top objectives will also lead to the accomplishment of other listed goals. If that’s not the case, repeat the process.

Study forecast

The Appleton Greene Operational Excellence (OpEx) corporate training program typically takes 12-18 months to complete, depending on individual availability and commitments. This distance-learning program combines academic theory and practical integration through real project studies, requiring important decisions and compromises. To plan your time, determine a realistic weekly study schedule, calculate program duration, allocate time to logical modules, and use tools like spreadsheets or personal organizers. Break tasks into specific to-do items, align them with relevant training modules, and consider using software for project management. By following these steps, you can create a clear and realistic forecast for achieving program objectives.

Performance management

Developing your study forecast is important, but monitoring your progress is equally crucial. It’s more important to update your forecast based on your actual performance, rather than simply achieving the original forecast. As you progress through the program, you’ll gain a better understanding of your personal performance and productivity as a distance learner. After completing each study module, reassess your study forecast for both time and tasks to align with your achieved performance. Measure your progress using an alarm clock, noting your accomplishments within hourly intervals, and compare them to your forecast. Analyze the factors contributing to your performance, positive or negative, and make informed adjustments to future forecasts. Over time, you should achieve your forecasts consistently.

Regarding time management, track your actual study time and note it in your study plan. Consider successful time-efficient strategies and incorporate them into future planning, as well as analyze failures and their causes to improve future time management. Continuously evaluate your study forecast in relation to time planning to maintain realistic expectations. Consistency in time management is crucial to completing your studies, ensuring you allocate enough time and maintain efficiency. Remember, taking control of your studies prevents them from becoming a source of stress.

For task management, track the tasks you complete during your study sessions and document them in your study plan. Identify successful task-efficient approaches and incorporate them into future planning. Analyze task-related failures and their causes, using that knowledge to improve future task management. Re-evaluate your study forecast in relation to task planning to ensure realistic expectations for achieving program objectives. Consistent task management is vital for assessing progress toward your objectives..

Keeping in touch

You’ll have access to highly qualified and experienced tutors who are dedicated to supporting your training program. Don’t hesitate to communicate with them about your progress. We maintain electronic records of all tutorial support emails, allowing tutors to review previous correspondence before providing personalized responses. This system ensures a comprehensive record of all communications between you and your tutors, minimizing duplication, misunderstandings, or misinterpretations. If you encounter any issues related to the program, please share them via email. It’s likely that your tutors have encountered similar problems before and can offer valuable suggestions and guidance. For more information on when and how to utilize tutorial support, please consult the Tutorial Support section in this student information guide. This will help you maximize the available tutorial support and ultimately contribute to your success and enjoyment of the training program.

Work colleagues and family

Don’t hesitate to discuss your progress in the program with others. Appleton Greene training programs emphasize practicality and collaboration. Engage with your colleagues, friends, and family to seek information, plan, develop, implement processes, and receive feedback. Distance-learners often receive sympathy and support, so don’t keep everything to yourself. Share your ideas and involve others in your journey. Your family and colleagues are likely to benefit from your program, so they may be more interested in participating than you realize. Delegate tasks to those who can benefit from them, fostering understanding and commitment. Share your experiences with friends and family.

Making it relevant

To succeed in learning, relate the program content to your own circumstances. Reflect quietly or engage in interactive discussions with colleagues, client partners, or family to bridge the gap between the material and your personal situation. This is crucial for translating your studies into meaningful self-improvement. Clearly define how the program can benefit you by setting study objectives aligned with understanding, concepts, research, activities, and their application to your situation. As you progress, your objectives may change. Update your study plan with revised objectives to have a constant reminder of what you aim to achieve, when, and why.

Distance-learning check-list

• Prepare your study environment, tools, and rules.

• Self-assess your ability as a learner.

• Define your study objectives and tasks.

• Forecast your workload, create a plan.

• Assess your study performance.

• Update your study forecast.

• Use tutorial support as needed.

• Update people around you.

Tutorial Support

Programs

Appleton Greene offers standardized and customized corporate training programs to instill business process improvement knowledge within client organizations. Each program targets the implementation of a specific business process, allowing clients to measure their return on investment effectively. With a wide range of established training products in areas like customer services, production, e-business, finance, globalization, human resources, information technology, legal, management, and marketing, we cater to diverse client needs. Regardless of the location of client employees, be it a single office or multiple international offices, we facilitate collective learning and implementation of business processes. Our global localization approach ensures an international service with a personal touch. Appleton Greene’s corporate training programs can be delivered virtually or locally, focusing on specific business functions. These programs span a sustainable duration and are supported by qualified learning providers and specialist consultants.

Available Support

You will have a designated Certified Learning Provider (CLP) and an Accredited Consultant, and we encourage you to communicate with them as much as possible. In all cases tutorial support is provided online because we can then keep a record of all communications to ensure that tutorial support remains consistent. You would also be forwarding your work to the tutorial support unit for evaluation and assessment. You will receive individual feedback on all the work that you undertake on a one-to-one basis, together with specific recommendations for anything that may need to be changed to achieve a pass with merit or a pass with distinction and you then have as many opportunities as you may need to re-submit project studies until they meet with the required standard. Consequently the only reason that you should really fail is if you do not do the work. It makes no difference to us whether a student takes 12 months or 18 months to complete the program, what matters is that in all cases the same quality standard will have been achieved.

Support Process

Please send all future emails to the designated Tutorial Support Unit email address provided. Avoid duplicating or copying emails to other AGC email accounts to minimize unnecessary administration. We aim to respond to emails as quickly as possible, but during busy periods, please allow up to 10 business days for general tutorial support email responses, as we prioritize them in the order received. This does not include weekends or public holidays. Evaluation and assessment of project studies may take up to 20 business days, so please consider this in your time planning. All communications are managed online via email to enable tutorial service support managers to review previous correspondence and maintain a copy for reference. Your personal study file at Appleton Greene will store all communications throughout your designated study period. If you require any assistance or clarification, please don’t hesitate to contact us via email. When asking questions, please list and number them concisely for specific answers to each query.

Time Management

The Operational Excellence (OpEx) corporate training program is typically completed within one year, consisting of 12 monthly workshops. Students are expected to dedicate approximately 4-8 hours per week of their personal time over the course of one year. They have the flexibility to study from home or work at their own pace and are responsible for managing their study plan. Evaluation and assessment are based on project study submissions, internal analysis, and supporting documents, without formal examinations. Students can allocate more or less time to their studies based on their availability. Most students are employed full-time while studying, and the program is designed to accommodate this, offering flexibility in time management. Whether students complete the program in 12 or 18 months, the focus is on achieving the same high standard of quality in both standard and customized programs provided by Appleton Greene.

Distance Learning Guide

The distance learning guide is your go-to resource for starting your training program. It provides guidance on planning your study schedule, creating an optimal study environment, and adopting the right mindset. Proper planning sets the foundation for enjoyable and productive training. The guide helps you adjust your lifestyle to accommodate study time and develop effective study habits. It aids in tracking your progress, measuring performance, and achieving your goals. It explains the necessary tools for study and how to apply academic theory practically. Take the time to thoroughly go through the distance learning guide to establish a strong foundation for maximizing your distance learning program. Attendance at Appleton Greene offices or workshops is not required. The entire program is conducted online, with course materials and project studies accessed through the Appleton Greene website and email. You can study at your own pace, comfortably at home or in the office, as long as you have a computer and internet access.

How To Study

The how-to-study guide offers students a comprehensive understanding of Appleton Greene’s distance learning training methods and provides an overview of the training program’s content. It explains the step-by-step approach used by Appleton Greene, the integration of course manuals with project studies, and the importance of research and evidence-based statements. The guide outlines the requirements to achieve a “pass with merit” or “pass with distinction” in individual project studies, while offering valuable guidance on fostering innovation and creativity when implementing the OpEx program within an organization.

Tutorial Support

Tutorial support for the Appleton Greene Operational Excellence (OpEx) corporate training program is available online through the Appleton Greene Client Support Portal (CSP) or email. Response times for general support queries are up to 10 business days, and evaluation and assessment of project studies may take up to 20 business days. This does not include weekends or public holidays. It is important to manage your tutorial support procedure effectively to make the most of it during your study period. Retain copies of your tutorial support emails and follow the suggested format provided in the tutorial support guide. Clearly reference the course manual or project study you’re working on and limit questions to a maximum of five per email. The guide explains how to use tutorial support effectively and maximize the benefits of your training program. Appleton Greene’s training programs empower you to take charge of your learning while providing the necessary structure and framework. Distance learning with facilitation offers long-term benefits compared to traditional knowledge-sharing programs. Learn how to utilize tutorial support to enhance your learning experience with Appleton Greene. The guide outlines the purpose of each training function, how to use them, and provides helpful tips and best practices.

Tutorial Support Tips

To maximize the benefit of tutorial support with Appleton Greene, it’s important to know how and when to use it effectively. This Tip List provides valuable guidance to help you make the most of tutorial support. Refer to it regularly to ensure you are utilizing the service properly. Tutorial support plays a critical role in your training success, and those who excel are often positive, proactive, and productive in their approach to utilizing tutorial support.

Communication Etiquette

When communicating with the tutorial support unit, remember that your emails are seen by real people. By adhering to the golden rule of treating others as you would like to be treated, maintaining a positive, complimentary, and friendly tone in your emails can elicit a similar response. This approach leads to a more enjoyable, productive, and rewarding experience. Remember that all tutorial support emails are stored electronically, and tutors refer to prior correspondence. Over time, a general opinion is formed about your character, attitude, and ability. Manage your frustrations and mood swings independently without involving the support team. Demonstrating patience and professionalism is crucial. Take advantage of written communication by carefully considering your content, reviewing and proofreading before sending. This helps you communicate professionally, consistently, and avoid unnecessary knee-jerk reactions. Keep in mind that the CLP Tutorial Support Unit is responsible for evaluating your work and providing recommendations to other learning providers and client contacts. Stay in control of your emotions and strive to make a positive impression.

Quality over Quantity

When contacting the tutorial support team, it’s important to remember that you’re not using platforms like Twitter or text messaging. Avoid forwarding an email for every fleeting thought, as it won’t be productive for either you or the support team. Instead, take the time to craft your communications thoughtfully, as if you were writing a professional letter to a business colleague. Create a list of queries you may have and incorporate them into one comprehensive email, perhaps once a month. This approach allows the tutorial support team to better understand the context, application, and methodology of your study. Establish a consistent routine for your tutorial support requests and utilize the provided tutorial support template in all your emails. Keep in mind that the Support Unit is not there to spoon-feed you information. They need to evaluate and assess your support requests carefully and professionally, so please prioritize quality in your communication rather than quantity.

Specificity and Conciseness

When writing tutorial support emails, avoid writing lengthy essays or thinking aloud. The tutorial support unit may become unclear about your specific question or desired outcome. To ensure you receive precise answers, be specific when posing your questions and consider numbering them. This allows for targeted responses to each question, which is the primary objective of tutorial support via email. Additionally, remember to keep a record of all tutorial support emails you receive. This way, you can refer to them when needed, avoiding any unnecessary duplication, misunderstandings, or misinterpretations.

Equal Opportunity Online Support

Appleton Greene provides tutorial support exclusively online and does not offer separate meetings, workshops, or telephone support for individual students. As an equal opportunity learning and service provider, we treat all students equally and cannot accommodate special arrangements or financial considerations for individual cases. Online support via email ensures that all communications are recorded for future reference, adhering to our quality management procedure and your enrollment terms and conditions. By numbering your questions and seeking clarification, you will receive specific and considered responses. This approach enhances productivity by preventing duplication, misunderstandings, or misinterpretations while maintaining a comprehensive record of your support interactions.

Standard Support Email Format

To ensure effective communication when seeking clarification or assistance during your training program, please adhere to the following tutorial support email format. It is essential that all tutorial support requests use this format consistently. We recommend setting up a standard email template for your convenience. Emails not conforming to this format may be returned. You can expect a detailed response via email within approximately 10 business days for general support queries and 20 business days for project study evaluation and assessment, excluding weekends and public holidays. Your tutorial support request and the corresponding Tutorial Support Unit (TSU) reply will be saved and stored in your electronic TSU file at Appleton Greene for future reference.

Email Subject:

• Tutorial Support Request: Topic XYZ.

Email Body:

• Reference (example: OpEx Workshop 1 Program Charter)

• Enquiry (maximum 5 topics, maximum 50 words each)

• Sender (full name)

Procedure:

• List the questions in number them in the order of priority.

• Reference them to the course manuals or project studies.

• Be specific and concise, maximum 5 question x 50 words each.

• Allow up to 10 business days for tutorial support emails.

• Allow up to 20 business days for assessment of project studies.

• Keep your email communication positive and professional.

• Try not to repeat questions have already been answered.

• Keep a record of all questions and replies for reference.

How To Study

Getting Started

Engage with your Certified Learning Provider (CLP) and Accredited Consultant to create a task list for a clear direction and priorities in your training program. This exercise serves as an introduction to the tutorial support team as well.

Creating an Optimal Study Environment

Ensure your study environment is conducive to a positive training experience. Consider factors such as space, comfort, privacy, and potential disruptions. The availability of study tools and facilities is also crucial for distance learning success. Seek guidance from your tutorial support unit to optimize your study conditions, regardless of your initial setup. Prioritize setting up a suitable environment before embarking on your training program.

Setting Clear Program Objectives

Before starting your training program, it is essential to establish a clear and prioritized list of study objectives. Your tutorial support unit is available to assist you in ensuring that your objectives are well-defined and given appropriate consideration and priority.

Strategizing Your Study Schedule

As a distance learner, you have the flexibility to study in a manner that suits you, at your preferred pace and for your specific goals. This method is intended to enable you to study effectively outside the confines of a traditional classroom setting. However, it is crucial to plan out how and when you will study, maximizing your innate abilities, strengths, and available opportunities. Your tutorial support unit is available to provide guidance and valuable suggestions, ensuring that you leverage your strengths to the fullest.

Planning Your Study Tasks

It is essential to have a comprehensive comprehension of the study assignments you need to undertake and their corresponding priority levels. These tasks should align with your program objectives. The distance learning guide and the guide to tutorial support for students are valuable resources to assist you in this process. However, if you require any clarification or assistance, please don’t hesitate to reach out to your tutorial support unit.

Planning Your Time

To ensure timely completion of your program, it is crucial to allocate specific time slots in your calendar dedicated to studying. It is your responsibility to plan and manage your study time effectively to achieve success. If you encounter challenges with your time plan, your tutorial support unit can help you overcome them.

Program Schedule

The OpEx program operates on a structured schedule with monthly modules to deliver operational excellence. These modules are further segmented into four sprints: (1) Preparation, (2) Development, (3) Implementation, (4) Review. This regular rhythm facilitates efficient planning and has proven remarkably successful in maintaining progress.

Keeping in Touch

Consistency is crucial when it comes to staying in touch. If you communicate too frequently in brief intervals or infrequently without a consistent pattern, it raises doubts about your ability to manage your studies effectively, both from your perspective and that of your tutorial support unit. The level of control you exhibit over your studies becomes evident, and this relies on your ability to adhere to your study plan. Inconsistency inevitably leads to unfinished tasks.

Tracking Your Progress

Your tutorial support team is available to assist you in tracking and documenting your study progress. For more information, please consult your distance learning guide.

Achieving Success

It is essential to fully dedicate yourself to your training program and accurately interpret its content. The responsibility for success or failure rests solely in your hands, so it’s crucial to have a well-defined strategy to make it work. Your Certified Learning Provider (CLP) and Accredited Consultant can support you in the process of program planning, development, and implementation, guiding you towards your goals.

Reading Methods

Interpretation is a subjective process, varying from person to person. However, consistent implementation of effective reading methods can enhance and even quantify interpretation skills. External factors such as family members, television, or the Internet, as well as competing thoughts, can interfere with interpretation. Employing recognized reading methods can boost productivity by enabling us to concentrate and approach information in a more organized manner, particularly when reading for essential purposes rather than leisure.

Speed Reading

During your initial read-through of course manuals, consciously set your reading speed to a level where you can’t dwell on individual words or tables. With practice, aim to read an A4-size sheet of paper in approximately one minute. While detailed comprehension may be limited, your brain will retain a valuable overview. This overview will prove important later, as it helps you maintain a broader perspective and recall information, as speed reading engages the memory center of the brain. Don’t worry about what you remember or don’t remember at this stage.

Content Reading

After speed reading everything, you can dive into focused reading. Choose a specific section of your course manual and read it thoroughly, taking detailed notes as you go. This process, known as content reading, helps solidify your understanding and interpretation of the provided information.

Structured Notes

During content reading, it’s crucial to make structured and informative notes. Use a word processing or notetaking application, such as Word or Notes, allowing easy modification and updates when necessary. Organize your notes under three headings: 1. Interpretation, 2. Questions, 3. Tasks. The interpretation section helps clarify your understanding by putting it into writing. The questions section enables you to note down any queries arising from the material. The tasks section is where you list any actions or assignments that need to be completed as a result. If you have a business-related degree, you may already be familiar with this note-taking process.

Organizing Notes

After creating notes, transfer them to a separate study notebook that allows for easy referencing, such as a Word document, Excel spreadsheet, notetaking application, or a personal organizer on your tablet or phone. This step enables cross-checking and verification, significantly aiding comprehension and interpretation. The more proficient you become at this process, the greater the likelihood of achieving your study objectives.

Clarifying Your Understanding

To ensure clarity in your learning process, it is crucial to question and challenge both your understanding and interpretation. Take the time to explain concepts and ideas to yourself using your own words and write them down. This practice helps solidify your understanding. If any uncertainty persists, don’t hesitate to reach out to your tutorial support unit via email. They are there to assist you in clarifying any uncertainties and refining your interpretation as well. Remember, active engagement in questioning and seeking clarification promotes a deeper comprehension of the subject matter.

Qualification Requirements

To become an Accredited Operational Excellence Specialist (AOES), you must successfully complete the project study and all exercises associated with the Operational Excellence (OpEx) corporate training program. Achieving a pass with merit or pass with distinction in each case is necessary. Additionally, all monthly workshops must be implemented and tested within the student’s company. These project studies offer flexibility, allowing completion at one’s own pace and in the comfort of their home or office. Unlike theoretical case studies, these project studies require thorough research and development of real program processes. They serve as a means to measure the student’s understanding and interpretation of the training program and serve as the basis for qualification assessment. There are no formal examinations; assessment is solely based on the successful completion of the project studies. The content within the training program forms the foundation for all project studies, enabling integration of learned concepts into corporate training practices.

Grading Contribution

The grading contribution for the project study “OpEx Program Charter” is distributed across various components, each carrying a specific weightage. The breakdown is as follows:

– Driving Force: 10%

– Vision Statement: 10%

– Anticipated Gains: 10%

– Required Resources: 10%

– Business Case: 10%

– Core Team: 10%

– Target Timeline: 10%

– Basic Skills: 5%

– Stimulus Plan: 5%

– Change Story: 5%

– Barrier Removal: 5%

– Control System: 10%

= TOTAL SCORE: 100%

The project study is evaluated holistically, contributing to a total grading of 100%. This comprehensive assessment provides a clear picture of the student’s competence in implementing operational excellence.

Qualification Grades

Appleton Greene’s qualification grades evaluate project studies in operational excellence, distinguishing exceptional performance from satisfactory results. These grades assess understanding, interpretation, content presentation, quality, and practical integration of academic theory. Feedback and guidance are provided for improvement, enabling students to resubmit their project studies until the required standard is met. These grades reflect a commitment to continuous learning and development in the pursuit of operational excellence.

– Pass with Distinction: 90% or higher

– Pass with Merit: 75% or higher

– Fail: Less than 75%

If a project study receives a mark below 75%, detailed feedback and a list of tasks will be provided by the Certified Learning Provider (CLP) or Accredited Consultant. These tasks aim to improve the project study’s quality to meet the required standard set by Appleton Greene. The student can resubmit their project study for further evaluation and assessment. Revisions can be submitted until the project study meets the required standard, as Appleton Greene recognizes this as part of the learning process. Project studies are assessed based on evidence of the following:

Pass with Merit:

– Satisfactory program understanding

– Satisfactory program interpretation

– Satisfactory project study content presentation

– Satisfactory project study content quality

– Satisfactory practical integration of academic theory

Pass with Distinction:

– Exceptional program understanding

– Exceptional program interpretation

– Exceptional project study content presentation

– Exceptional project study content quality

– Exceptional practical integration of academic theory

Preliminary Analysis

Preparing for the Journey:

Great news! You don’t need to dive into formal analysis before our first workshop. Instead, let’s embark on a journey of self-reflection and exploration to prepare for the exciting OpEx program ahead. Get ready to make it inspiring and fun!

Review Your Own Kitchen: