Technology Invoked Change

The Appleton Greene Corporate Training Program (CTP) for Technology Invoked Change is provided by Mr. Horrocks Certified Learning Provider (CLP). Program Specifications: Monthly cost USD$2,500.00; Monthly Workshops 6 hours; Monthly Support 4 hours; Program Duration 12 months; Program orders subject to ongoing availability.

Personal Profile

Mr Horrocks, M.SC, B.Eng., C.Eng. has had a long career dealing with technology in various industries beginning in his early years as an engineer with the application of computers to machine tools both in structural Analysis and automated tool changing. His development with technology has followed both the computer-based developments through CAD, CAM, CIM and robotics to materials such as carbon fibre and the use of lightweight metals. He has been in the vanguard of introducing critical technology applications, such as low-power lasers for aligning machine tools to applying visual simulation techniques for assessing manufacturing lines and warehouse design.

As the technology matured, Mr Horrocks moved from the technical design to implementation, exploring why seemingly good projects and technologies failed. This led to change management and the impact that technology has on both people and processes.

Mr Horrocks began his career in machine tools after taking a mechanical engineering degree and a master’s in machine tool technology, focusing on designing future machine tools, for example, replacing cast structures with fabricated ones. This is Mr Horrocks’s genuine interest and capability in analysis and using computer tools to provide data for decision-making. Mr Horrocks next career move was into production consulting, analysing, and improving production processes.

Gradually Mr Horrocks became engaged in computer systems for design, process planning, and commercial processes, covering designing new applications and supporting customers with their implementation. Implementation work developed from training on new transactions and data migration to helping the organisation through the required change. Again, this aligns well with Mr Horrocks’s natural disposition to create solid personal bonds, building strong customer trust.

• Depth of research

• Depth of experience

• Ability to relate customer situation to his experience.

• Anecdotal capability

• Simplifying tools and examples

• Good presentation skills

• Has undertaken the work personally within a wide range of industries and company profiles.

Mr Horrocks delivers engaging workshops and support materials; his rich tapestry of experience across different industries, company sizes, cultures, and ownerships enables him to relate to each client’s unique situation quickly. His style enables him to challenge management teams and proffer solutions when they appear stuck, changing the status quo. Mr Horrocks brings leading-edge tools that provide insights and vital decision-support information. Mr Horrocks has a lengthy mentoring background and is an experienced exponent of the art through online mediums.

To request further information about Mr. Horrocks through Appleton Greene, please Click Here.

(CLP) Programs

Appleton Greene corporate training programs are all process-driven. They are used as vehicles to implement tangible business processes within clients’ organizations, together with training, support and facilitation during the use of these processes. Corporate training programs are therefore implemented over a sustainable period of time, that is to say, between 1 year (incorporating 12 monthly workshops), and 4 years (incorporating 48 monthly workshops). Your program information guide will specify how long each program takes to complete. Each monthly workshop takes 6 hours to implement and can be undertaken either on the client’s premises, an Appleton Greene serviced office, or online via the internet. This enables clients to implement each part of their business process, before moving onto the next stage of the program and enables employees to plan their study time around their current work commitments. The result is far greater program benefit, over a more sustainable period of time and a significantly improved return on investment.

Appleton Greene uses standard and bespoke corporate training programs as vessels to transfer business process improvement knowledge into the heart of our clients’ organizations. Each individual program focuses upon the implementation of a specific business process, which enables clients to easily quantify their return on investment. There are hundreds of established Appleton Greene corporate training products now available to clients within customer services, e-business, finance, globalization, human resources, information technology, legal, management, marketing and production. It does not matter whether a client’s employees are located within one office, or an unlimited number of international offices, we can still bring them together to learn and implement specific business processes collectively. Our approach to global localization enables us to provide clients with a truly international service with that all important personal touch. Appleton Greene corporate training programs can be provided virtually or locally and they are all unique in that they individually focus upon a specific business function. All (CLP) programs are implemented over a sustainable period of time, usually between 1-4 years, incorporating 12-48 monthly workshops and professional support is consistently provided during this time by qualified learning providers and where appropriate, by Accredited Consultants.

Executive summary

Technology Invoked Change

Implementation of any form of technology comes with a unique set of challenges ranging from validating the type and condition of technology to be implemented to extracting the value promised. Technology Invoked Change brings together best practice tools and techniques that enable management teams to maximise the success they can extract from any project.

Throughout the course, the emphasis is placed as much on the people and process aspects as much or more than the technology; because no matter to what level of automation is being implemented, there will be underlying processes with associated business rules and some interaction between the technology and a human being.

Each course module will reinforce the People-Process-Technology mantra to become second nature to all students. We guarantee that you will become better equipped to manage technology projects and the resultant change without the need to understand how the technology is built and implemented.

How do we feel confident we can guarantee this outcome?

In all technology projects, there will be a level of technical skill required, which will likely be beyond your reach as business leaders. Therefore, can you still lead the project? Applying the correct management principles in engaging with external suppliers, employing technical support personnel, and selecting technology.

Jeff Bezos is an excellent example of someone who has successfully employed and developed leading-edge technology with a high-level technical background from college only, from customer portals for managing orders and reviewing purchased history to the use of AI to suggesting other purchases to warehouse robotics and virtual shops performing pick and despatch functions.

Insert jeff bezos’s profile.

By focusing more on people and process change aspects, leaders can effectively manage the project implementation by challenging technologists to demonstrate how they will deliver a solution to the processes defined and the impact on the roles and responsibilities of people. The benefit is greater confidence in discussing requirements with technicians and, with tools learned later in the programme, higher levels of capability in managing projects.

Managing the scope of technology implementation is fundamental to project success measured in scope creep, unnecessary developments, cost, and time overruns. By focusing on processes and applying techniques enabling the evaluation of any change introduced through technology, leaders can challenge the internal team and the technology vendor. Extending these techniques beyond the high-level process view to features and functionality analysis provides a robust basis for decision-making.

The ability to understand processes that drive the business, the impact that technology can have, and at what cost strengthens an executive’s position within the team and in the eyes of the vendor. It enables the executive to make better decisions in selecting the technology and the implementation partner.

Understanding how the technology will transform the company’s position vis-a-vis the market requires insight. Using a company’s resources at its disposal, in many cases at little cost, can provide the backbone of horizon scanning in terms of technology that might apply to the business. Coordinating inputs from salespersons, internal suggestions, customer complaints and surveys, and competition analysis with some basic research in market journals, maybe combined with liaisons with research institutes, will provide a rich vein of information to drive creativity.

We will discuss how to productionise this effort to manage the information into coherent opportunities.

The course will help executives review and outline their process and apply measures to ensure it is managed and operated to benefit the company. It will identify key innovations to help achieve the strategic goals and avoid costly mistakes.

Horizon-scanning: how to plan for alternative business futures Wilson Wong CIPD

Executives need to be sure that projects that they back with resources move the company forward in terms of the market, such as improving the customer experience, making the company more competitive and improving the engagement and retention of staff. During the course, we examine how defining the criteria relating to the strategic alignment of projects can help assess fit. Then, add other dimensions, such as resource requirement and returns on investment, enabling executives to contrast and compare outcomes and make more robust decisions.

Closely coupling this process with market research helps avoid disasters like Web Van.

(Webvan was one of the first online grocery stores and is among the most famous Dotcom Bubble busts. The company raised nearly a billion dollars from investors but went bankrupt after two years of operations. Webvan’s strategy of “growth at any cost” was characteristic of many failed Dotcom Bubble companies. Courtesy of Street Fins) Webvan: The Dotcom Bubble’s Biggest Bust | StreetFins®. www.streetfins.com

… more match the success of Deliveroo;

“It met a classic untapped need,” he said. “The growth from the very early days was viral and customer-driven.”

“The Founder executed his plan for Deliveroo extremely well by paying attention to the big picture and the little details. And he brought in the right people.”

Courtesy of London Business School

Previously business success could be measured through product and service quality, operational cost management, innovation and supply chain robustness. Now the impact of the environment and climate change has added another dimension. According to the Harvard Business Review, leading advocates in developing countries vividly demonstrate that trade-offs between economic development and environmentalism aren’t necessary. Instead, the pursuit of Sustainability can be a powerful path to reinvention for all businesses facing limits on their resources and their customers’ buying power.

Understanding how a sustainable approach can lower costs, improve yields, and build new business models that are challenging to emulate will be vital to driving future business performance improvement.

Broadening the standards addressed beyond quality control to embrace Sustainability and environmental legislation should be integrated into the technology and implementation plan. The course will demonstrate how these standards can be applied to idea generation and development and new business models; and how the new frameworks will provide frameworks for measurement and management.

Typical results quoted by BSI are:

• 63% attribute direct cost savings to ISO 14001

• 74% report improvements to their corporate reputation

• 76% improve their compliance

• 61% report higher morale among staff

www.greenjournal.co.uk

To successfully implement change, whether driven by technology or not, it has long been recognised that executives need to articulate their vision for the business and demonstrate their commitment to change with specific actions to contribute to change. During the course, we ask the business executives to propose a project to exercise these skills and support with tools such as the Business Model Canvas and Target Operating Model to distil the essence of the future state.

As we move through the course, the vision will change due to internal and external factors requiring review and recommunication. Stakeholder management and tools to support different forms of communication depending on the audience will discuss and practice along with case-studies from good storytellers and visionaries such as Jack Welch (GE), Steve Jobs (Apple), Jim Ratcliffe (INEOS) and others.

The course will also examine how it is essential for a senior executive, not just the CEO, to provide a vision for your team that connects with the overall vision.

As well as embracing stakeholder communication, we will demonstrate the importance of training for all staff so they can comprehend and contribute to the change. These programmes are a good vehicle for upskilling employees in decision-making, problem-solving and team leading, for example. Reviewing the development of online training resources and virtual collaborative working environments will show these technologies help to facilitate better educational success leading to greater acceptance and implementation of change and enabling staff to learn at their own pace using collaboration with colleagues to resolve their understanding.

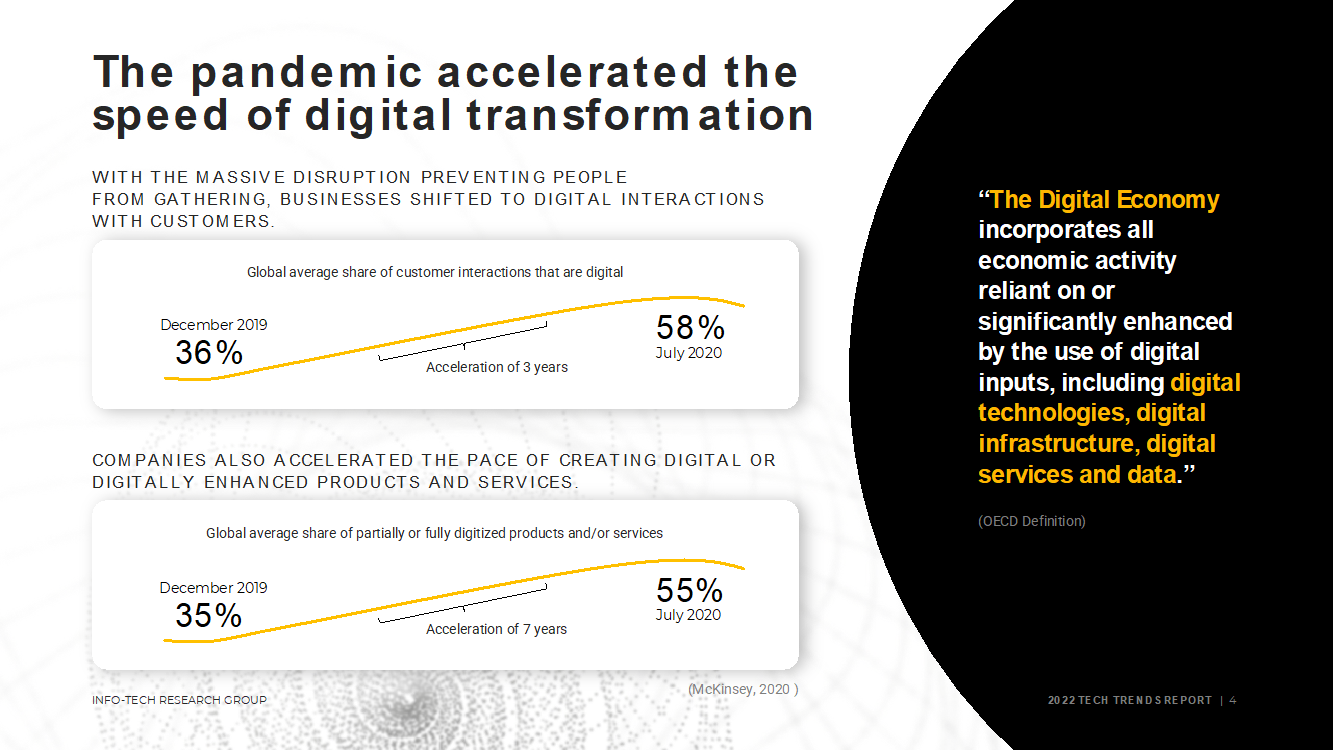

Digital technologies have rapidly transformed the information landscape, particularly over the last 20 years, from design technologies such as 3D and printing to intelligent phone-based applications. The graphic below shows the growth over the previous seven years leading to 30% more IT professionals expecting a permanent transformative change in the next 12 months (2022), up from less than 15% in 2021.

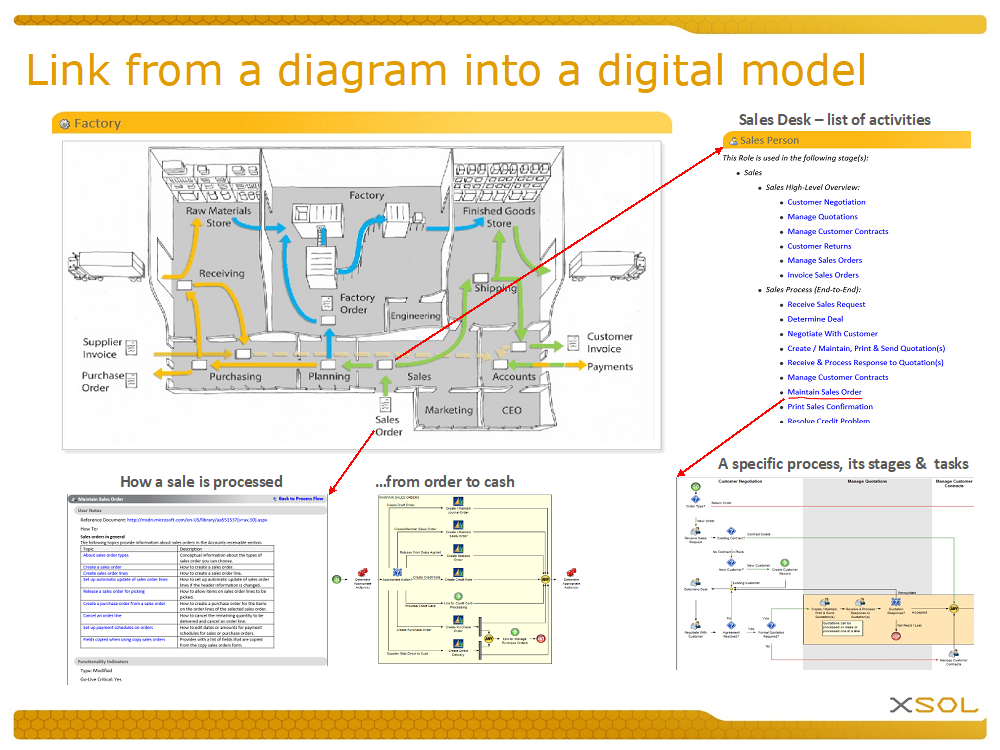

One of the transformative technologies that have become embedded in high-value and complex manufacturing has been coined as ‘digital twinning’, which started in automotive engineering and aerospace and has been rapidly adopted across construction and maritime industries. We will demonstrate how this is being applied now in implementing change. We explore the application of digital technology in process modelling, not just static diagrams but also hierarchical models that can be flexed with analysis tools such as ‘lean’ and ‘customer experience’ and then tested.

Visual industrial simulation was one of the first technologies to be applied, enabling engineers to share large-scale automation on a screen with executives and facilitate operational experiments. This can be replicated in administration processes that are difficult to imagine. As an executive getting closer to the front line, understanding the impact and benefit of change will provide greater confidence and confirm the support required for success.

Explain this diagram more by breaking it up.

Thus the ability to visualise the new business at the process level confirms the need for training across the enterprise. Building tailored training curricula is quick and easy with the tools and techniques online by understanding your company’s culture and existing skill levels and identifying internal change agents. The ability to implement the change internally is fundamental to its Sustainability and speed of application. It will also facilitate the ability to reduce the external costs of implementation.

Successful implementation of technology will require detailed project management of both the technology and the internal change; project management must combine both elements and require an internal resource to face off with any partners. Understanding the critical project management principles enables executives to fully engage Project managers in conversation, understand reporting outcomes, and be aware of requests made to make changes. The benefit will be more honest reporting and less overrun regarding time and resources.

Technology implementations must be measured regarding corporate and personal (staff) benefits. Selecting the correct measures and a timescale of realisation will be shown to be part of the project management portfolio as part of the plan relating to how the technology will impact the business process model.

Alongside using Project management skills, we will explore how Process Ownership will be a vital element of this and how as an executive, you can re-align your management team from departmental silo management to end-to-end processes and apply appropriate key performance indicators. Target Operating Models, in this instance, can help with the ongoing visualisation of how the business will look and feel in the future.

Using the examples of the End-to-End processes modelled as part of the Business Process Modelling exercise, we can align these with business roles to flesh out the Target Operating Model and then overlay this with the Organisational Command and Control system. This will enable the executives to explore resource management and process measurement issues.

Executive Summary – Key points

Technology Leadership and technical skill

The learning in this module is that to lead a technology project, business leaders need a level of understanding to manage technical experts and the impact of the technology in terms of people and processes.

Cartoon using clip art of different skills

Potential example Jeff Bezos

Scope of Technology Implementation

This learning is focused on the process that management can use to evaluate the scope and type of technology; when considering digital-based technology, typically such as integrated or ‘best of breed’ solutions. For other technologies, the decisions will focus on features and functionality.

Horizon scanning using customers and competition

To be able to lead and select technology, this learning explores market research and the need to manage this process well and integrate all the possible sources, including staff, public information, competitor analysis and customer feedback. How in non-digital areas, links with suitable research bodies can be vital. Market Research should be continuous and agile to react to market and industry changes. Managing external resources can also be critical to this being successful.

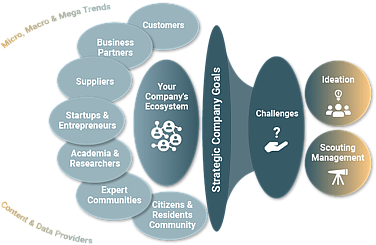

Diagram showing how the different sources can be melded and analysed

Fact from an Article from Wilson Wong CPD expert

Relate technology impact to the market.

Application of technology can be seen as a ‘me too’ or vanity project; the implementation of technology must be seen in terms of business performance, be it market share, improved margin or new market development. Learning how to evaluate opportunities and rank alternatives objectively is part of this module.

Diagram reflecting the impact on costs and timescales of both good and bad decisions

Examples such as Web van (poor) and Deliveroo (good), plus the use of the J curve

Impact and Sustainability

Businesses are also now judged, as well as costs and benefits that can be measured quantitatively. Their approach and implementation of social and environmental actions can impact their performance. Understanding the impact of new standards and also customer reaction/intentions. This requires other forms of research and horizon scanning in legislation and the political landscape.

Examples of achieving standards include B Corp and abstracts from an HBR article on how Sustainability can impact profitability.

Visioning and storytelling of the future state

This learning focuses on articulating the introduction of any new technology and the associated changes from a business and personal point of view. Capturing the need to embrace and demonstrate commitment and participation in any changes.

Examples of good storytelling executives are Jack Welch, Steve Jobs, Jim Ratcliffe.

Training and communications with all staff on the change

Training must be considered in the round, not just in the technology, system or process but in new skills. This level of disruption can provide a perfect backdrop for broader training objectives and general upskilling of staff. Measuring organisational capability in these terms will enable a better focus on its implementation and outcomes.

Digital transformation integrates and demands process understanding.

For example, the rapid development of digital technologies and sustainable materials means that leaders can get paralysed in their decision-making due to a fear of making the wrong choice. To mitigate this, learning to be able to understand the business process model, how you can flex it, and the impact in terms of people and process, as in other areas of design, system design is best done with a digital twin of the real world, provides a platform for meaningful exchange between process operators, their managers and business managers.

Diagram/picture of a digital twin process model.

Extractions of Models, maybe

Digital transformation requires process agility and no residual change resistance.

Faster technology development leads to a need to review processes more regularly and to have an open mind on change. Developing the internal change capability across several skills becomes fundamental in managing costs and making any change proposed more acceptable and sustainable.

Digital is making transformation quicker than ever, demanding fast and robust decision-making.

Decision-making during a business transformation involving technology will be required at all levels; appropriate tools and how to use them will be essential parts of the training programme and must be married with proper levels of responsibility/mandates to reduce the traffic of decisions being passed up the organisation.

Cartoon of words of typical decision support techniques.

Tech target facts on the pace of Change in Digital

Internal project management is needed despite any technology partner plans

Project Management can be delegated either consciously or not to the primary provider of the technology. As internal resources will inevitably be employed, management needs to ensure that internal resource constraints are integrated into the external partner’s plan. Understanding the project management principles and applying the correct level of control is vital, mainly in reporting progress.

Clipart of project timeline.

Project management must embrace both change and technology implementation.

As stated above, the close integration of technology and change (related to people and process elements) is vital to enable successful implementation. This can be achieved through integrated or individual plans with recognised touchpoints. There are several Project Management tools, so close coupling might be challenging. The minimum integration will be through regular reporting on progress, issues, and risks.

Assess set targets and monitor benefits.

The final focus is defining the most appropriate measures as Key Performance Indicators (KPI) to measure the project, ensuring both leading and lagging indicators. As for applying these, it is helpful to understand that these measures are not predictable. Therefore, tolerance levels around the chosen criteria will allow market and environmental changes. The quality control approach also ensures that reporting can be more honest.

The diagram of how this might work for a particular measure

Use of balanced scorecard examples

Process Outline

Process of development to effectively implement technology

1. Technology Impact/Pace

2. Identifying suitable Applications

3. Building Technology Leadership Capability

4. Understanding the impact

5. Process model, design and management

6. Change Management

7. Change Leadership

8. Technology Vendor Selection

9. Business Case

10. Change & Implementation Planning

11. Implementation Management

Curriculum

Technology Invoked Change – Part 1- Year 1

- Part 1 Month 1 Technology Development

- Part 1 Month 2 Technology Identification

- Part 1 Month 3 Technology Leadership

- Part 1 Month 4 Analysing Impact

- Part 1 Month 5 Business Process Models

- Part 1 Month 6 Managing Processes

- Part 1 Month 7 Change Agenda

- Part 1 Month 8 Technology Selection

- Part 1 Month 9 Business Case

- Part 1 Month 10 Establishing KPI’s

- Part 1 Month 11 Change Management Plan

- Part 1 Month 12 Change Leadership

Program Objectives

The following list represents the Key Program Objectives (KPO) for the Appleton Greene Technology Invoked Change corporate training program.

Technology Invoked Change – Part 1- Year 1

The program’s mission is to:

1. Embed a process within the organisation to effectively manage selecting, purchasing and implementing technology within the business.

2. Build the Competence of business leaders to identify technology, select appropriate vendors and manage their teams and vendors in its implementation.

3. Build communication and listening skills across the business so that the rationale for change and its benefits are fully understood, and buy-in is achieved with most staff.

4. Build support processes in areas such as horizon scanning.

5. Developing a project portfolio process that embraces not just the digital aspects in the process but those applied to sustainability and appropriate products/services, which might include.

6. Provide a suite of tools and templates that speed up decision-making and remove any subjectivity.

7. Introduce key techniques that make the capturing, analysing and remodelling processes faster and easier to assimilate.

8. Promoting the concept that there is a need for a core team of staff across all levels of the business that are skilled in change tools and techniques.

9. Developing the project and programme management capability to the point of establishing a Project Management Office for larger projects and continuing developments.

10. Embedding a benefits assessment and monitoring process that operates with traditional return on investment analyses and can be tracked back to actions undertaken as part of the implementation and adoption of technology.

11. Implementing or improving the balanced scorecard approach to ensure the value of any technology is correctly measured, and plan adjustments can be implemented rapidly to effect the outcome.

- Part 1 Month 1 Technology Development – Examining the history of technological innovation from the early industrial revolution through process analysis and improvement to digital transformation. Looking not only at the speed of development and adoption but the impact on workers involved in the implementation. Understanding the lag between the performance of the technology and the support given to employees and, latterly, the transformation of the world of work challenges the way we think about the social fabric of society as the level of manual tasks falls rapidly, and our lives become digitally transparent. How we have adopted and applied technology is the result of several factors, including but not exclusively the perceived threat to our livelihood, how the technology is presented in terms of ‘what is in it for me and finally, what will be the impact on my community and more latterly the impact on the planet. Exercises can include a self and company technology adoption and target questionnaire.

- Part 1 Month 2 Technology Identification – The application of technology requires a clear strategy from a business and technology perspective. To gain a clear view of the vision of the future, the company should constantly be scanning the horizon across markets, industries, customers and competition. Gathering intelligence needs to be structured so the results can be presented in an easily digestible form to enable any decisions to drive the company towards its short- and long-term objectives. In broad terms, these objectives include a number of the following Market Growth, Improved Profitability, Increased Sustainability and Higher Productivity. As businesses cannot manage all objectives simultaneously, these may be weighted to facilitate scoring individual or combination strategies. Alongside the setting of the business strategy, the technology strategy will be an enabler; this also requires intelligence gathering across subjects such as materials development, digital automation, mobile devices, service provision and process automation. The story of new management techniques will also impact the application of technology and its success rate. Business transformation will require senior management to understand the business model well. Developing a digital twin base on End-to-End processes provides an unambiguous definition of how the business works and where there are opportunities for improvement and change.

- Part 1 Month 3 Technology Leadership – Following the identification of the potential technologies that meet the strategic objectives, Leadership will need to be shown in selecting and implementing the identified technologies. Several key areas need to be addressed, including; Communication of the vision, Identifying and building a change cohort, and Allocating process and data ownership. Communicating the vision requires skills in storytelling and the ability to address the ‘what is in it for me?’ question that will be on all management and staff minds. Delivering a vision with passion and drive helps to cement commitment and motivation to change. Building a change cohort will need business leaders to create a balanced team and train them in crucial change management skills such as problem analysis, Lean analysis, decision making, solution definition and communication—the latter both internal and external. The critical part of any technology-invoked Change will be the impact on the business processes and the need for more automation to be introduced to manage the data. In both these cases, ownership will be essential, as will the application of targets for performance. As technology implementation tends to be transformational regarding employees’ daily tasks and responsibilities, leaders must recognise that demonstrating their ability to change is at the vanguard of their behaviour. Understanding any technology in depth requires study and application and, in most cases, across more than one discipline; therefore, the ability to source, select and manage the right technology partner will be critical, requiring a robust process that not only validates the technical capability but also ensures a good fit culturally.

- Part 1 Month 4 Analysing Impact – To correctly assess how and when to implement the chosen technologies, management must evaluate the impact on processes, the staff undertaking them, or the customer. The effect should be assessed from both a qualitative and quantitative perspective to enable an estimate of the Return on Investment, balancing costs against benefits. The starting point is to review and understand your business process model; ideally, this should use tools as discussed in the next module, which provides a digital twin of the business and can support scenario testing of potential changes. Assessment at this level will look at several criteria, such as the customer experience for outward-facing delivery processes; lean analysis reviewing the added value or not of procedures and streamlining when processes have become poorly designed over many years. In that case, we might examine how the present organisational structure creates silos and poor performance. A robust analysis will review the costs of change and the potential benefits and ensure that the changes are implemented in a sequence that aligns with achieving the Critical Success factors defined by the future vision. Impact on processes can be qualitatively assessed by reviewing the effect against criteria such as Displaced Costs, Improved Productivity and Increased Revenue and ranking the mark in terms of its difficulty to implement. This will be affected by the level of resistance to change and the degree of influence the company will have over the preferred outcome. Alongside this analysis, the impact on staff is essential, and this relates to their role in the business, the tasks they will be performing and any changes in responsibility.

- Part 1 Month 5 Business Process Models – As described in module 4, understanding and testing business models is vital when undergoing transformation programmes. It is a proven fact that poor implementation of process change required when introducing technology such as Enterprise Resource Planning software can have devastating and expensive long-term effects. Using technology to help negate these results can be achieved using digital models. This has been called ‘digital twinning’ and began in automotive manufacturing first and has now become synonymous with aerospace and complex new concepts, mainly where they are disruptive. Process models drive end to-End thinking, encouraging the management to change their focus from the organisational design, which tends to reflect the command-and-control elements of the business, not the delivery of products and services to customers—thinking about ‘What’ the company does and ‘Why’ before detailing “how’ the company does things will support the question of both the organisational structure and business rules. During the ‘What’ we do analysis, we examine how these processes are managed in terms of both who is in the organisation and against what targets. Using a digital model also permits better analysis from both the lean and customer experience perspectives. Completed digital models can provide repositories for work instructions and as documentation to support various ISO standards; used for training and induction. Making it available on the internal system means it will be maintained constantly instead of to satisfy periodic inspections and certifications.

- Part 1 Month 6 Managing Processes – This element of managing change driven by the introduction of technology first requires understanding the quality and performance of processes, second the potential for improvement and how technology can be applied, thirdly what impact is on staff, how this can be mitigated and finally, how to manage the processes in the future. Business process models enable us to manage the ASIS and TOBE state for comparison and analysis; analysis will take the form of lean and customer experience. Taking a Lean approach will examine processes and process steps from the point of view of added. By identifying low or non-added-value processes, management can change to process structure to remove these or apply automation to reduce or remove the human element. Customer Experience approaches process analysis by examining the process steps against three criteria; moments of truth which usually is the first point of contact between the customer and the company, and does this give a good first impression. The second looks at the impact business rules that enact processes have on a customer’s experience. Finally, we review handoffs between departments, called breakpoints, where customers can find themselves stuck or delayed. Both techniques highlight over-complex processes and help thinking on streamlining and automation. Using cross-functional teams helps understand business rules and departmental/functional handoffs. Innovation in the customer experience space might relate to Empowering them to do more within the sales process, introducing Sustainability to the process and finally, making the process Efficient. Training internal teams to do this work means building a toolset to address techniques such as Brainstorming, decision-making and innovative thinking and bringing technology forward within the creative thinking like Robotic Process Automation or Integrated Solutions such as ERP. Once the analysis is complete, staff should be capable of presenting the findings to their peers and articulating the vision. The modelling of the processes enables management to understand resource impacts from several angles more fully; Skill profile, Capacity, Data and decision-making responsibility. Using this information provides insight into manning, training, and organisational structure. In parallel, we look at process KPIs and ownership, divorcing the end-to-end process management from resource pools within the command-and-control system required to deliver resource management, including reward and recognition, training, and absence/vacation.

- Part 1 Month 7 Change Agenda – Following the process analysis covering the process, staff impacts and potential technology implementations, the requirement is to combine these into a coherent plan with the appropriate change management actions to support them. Typically we will pull together listed by the process; Problem, Chosen Solution, Technology to be applied, Staff actions such as re-training, job role and counselling. Compiling these activities will enable us to align appropriate change management techniques for communicating the vision, consulting on the job and organisational changes developing and delivering training courses and new work instructions. Technology at this point will be defined at a high level to select the specific technology, and any delivery partner will require the creation of an internal team representing the functions impacted and a robust process for defining the functionality, reviewing potential solutions and partners, arranging demonstrations and building a business case. Successfully developing and managing the agenda will require us to manage all the stakeholders, from staff to shareholders, with communication tailored to suit the audience regarding content and frequency. Capture all the proposed changes, measure the impact and benefit, and apply early project/programme management techniques. These will include timeline and dependency planning, risk management and assessing each area under change for their readiness.

- Part 1 Month 8 Technology Selection – Successfully implementing any technology will require a clear statement of requirements matched to the strategic need compiled by the business areas to which the technology will be applied. Managing the selection will require the high-level functional statement to be converted to ‘Use Cases’, which describe how any specific process will use the chosen functionality. Using Use Cases enables staff executing the process to test the functionality. By understanding the process at this level, management can also establish the weighting of the process to the strategic impact. Managing the scope of technical programmes and understanding the level of integration required as software becomes more of a commodity process management can be achieved with single applications or combining ‘best of breed’. During the evaluation process, we must objectively assess the performance of the technology in terms such as User Interface, ease of adoption and access to information. As any technology application will involve a partner, considering the inevitable internal disruption requires that there needs to be consideration of the match to the company’s cultural norms. Finally, costs are easily measured and must be offset by the potential benefits; an executive assessment of benefits will also leverage the processes used to define the use cases. A robust evaluation will account for different categories of benefit from displaced costs, improved productivity and increased revenue; also aligned to how easily the benefit can be achieved. Using financial tools such as Return on Investment can combine the cost and benefit assessments.

- Part 1 Month 9 Business Case – Before engaging on any change project, it is part of the governance that you pull together a business case content which will include; Future business vision, Competitive positioning and potential response, Market Impact, Implementation Milestones and Targets, ROI Model based on process benefits derived from the Executive Benefits Assessment, internal costs and external consulting and technology costs, Risk Assessment and Mitigating Action Plan, Technology Selection Rationale. Developing these sections will build on earlier work, slanting the outcome to make the information easy to absorb and encourage senior management and staff to commit to the programme. The business vision needs to paint a picture of the business and those served by it and operating within it. It should answer the question ‘what is in it for me?’ from customers and staff. The competitive analysis section needs to identify the business position vis a vis competition and what the change enables regarding the bottom line and maybe market share. The Return on Investment will provide the frame of reference for spending and benefit that aligns with the change required to achieve the stated result. Any change programme is not without risk, especially when humans are involved and their livelihood. Communicating clearly and allowing two-way exchanges are vital in one-to-one scenarios and small groups, often led by internally appointed change agents rather than senior management or consultants. Allow plenty of time for consultation, any job/role change, and re-training or support for finding other employment. Finally, the business case needs to timeline against which the technology implementation, change programme and costs/benefits can be laid out at a high level; interdependencies should be identified, and the impact of any failure to complete depends on actions on the whole plan—a little like Critical path Analysis but a higher level.

- Part 1 Month 10 Establishing KPI’s – Transformations driven by technology require a clear set of measures related to specific strategic targets, processes or internal development. This overall approach will cover both customer and financial targets, process improvement measured in terms of cost and time and also the customer experience, and finally, the company’s internal development such as organisation capability, information management and the internal and external supply chains. When establishing targets, it is recommended that at least three targets are applied. This allows recognition that considering all the dimensions of conducting business, customers, markets, geopolitics, and climate change, for example. The middle target would represent the best outcome, the upper target represents the maximum that could be expected, and the lower target represents the point at which a plan change needs to be changed. Targets then need to be set against the programme timeline, recognising that for many of the changes implemented, the impact will only be seen up to 12-18 months post-implementation. Considering this, the targets should be set quarterly, reflecting the agreed final target.

- Part 1 Month 11 Change Management Plan – Once the change agenda has been agreed upon, the next steps are establishing a timeline that integrates the technology application with the process and people aspects. We start with the usual project management techniques with timelines, milestones and activities. Defining the dependency between technology elements, people (such as training) and process design (including business rules/policy). Training plans need to cover both functional pieces of training, which will require competency testing and any role and responsibility training. If the changes have created spare time, we may need to add new skills to the employees. Designing an easy-to-understand plan may require work streams that reflect strategic themes such as sales and marketing or subject topics such as organisational capability. Having tested the reality of the plan regarding activities and durations to meet the programme objectives. Applying internal resources and the plan will enable an assessment of load against availability; to address any overloading options will be extending timescales, the usual project drifts or hiring additional resources. Any changes need to be reflected in programme costs. Internal resources need to be upskilled, both in the application of new functionality and any analysis and communication skills; when deciding who should be change agents or Subject Matter Experts, ensure that they provide a good team profile with the right profile of skills and skills personality. The broad impact of technology implementations requires clear documentation of the outcomes at the process and transaction level; using the business process model can reflect the changes and act as both a training and induction tool.

- Part 1 Month 12 Change Leadership – Change leadership can be the difference between success and failure though the style delivered will vary from each manager’s personality. The fundamental principles will still be the same, including: Personal activity ‘walking the talk.’, Encouraging junior staff to take Leadership, Celebrating Successes, Using Failures to modify the approach. As with all leadership activities, the future vision must be maintained and communicated and is inherent in technology implementations; the concept might change, which must be reflected. Regular communication using small groups to introduce 2-way communication and whole company broadcasts. Use all the available media, including videos and podcasts distributed through the company intranet.

Methodology

Technology Invoked Change

Program Planning

All the research for this programme has been derived from practical experience over 40+ years of delivering new technology to businesses. Starting with simple computer programmes to support the development of Process Planning and the calculation of Operation times from Standard data to the implementation of visual simulation of manufacturing and Warehouse operations and the development and implementation of integrated software solutions for running a business.

Successful implementation in all these cases requires that senior management is convinced of the benefit and can envisage the future of the business with the technology applied when the technology is the automation of a physical process such as replacing the creation of parts by hand laying carbon fibre for aerospace parts, such as the tail fin, for example with a robot. The benefits are straightforward to see and calculate. The key issue is redeploying the affected workers and training staff to manage the robot.

Digital technologies are much more difficult to assimilate and, therefore, to assess benefits for implementation. For example, using visual simulation ensures that the risks of employing the technology are reduced and for processes and installations that are brand new, setting standards and business rules for operation. An example of the former would be putting the work content and scope for an automated line to avoid bottlenecks and providing right-sized inter-operational Storage; for a warehouse operation, we can test rules for controlling robot picking trucks that there is no likelihood of damage at junctions whilst maximising the utilisation of the trucks picking and transporting the product.

When considering the management of data through software applications, this is even more difficult due to the lack of transparency at the senior management level of several factors; process structure, business rules applied in their execution and the handoffs created by the interaction between the cross-functional end to end processes and the departmental structure. This results in communication challenges arising from a wider audience involved in change, training is required for most staff, and change impacts occur in processes, business rules and business roles. The change will require more collaboration with staff and particularly departmental heads. With this level of complexity comes the need for more planning and management and a status understanding of the technology that gives the confidence to challenge internal and external experts.

The technology Invoked Change Programme, therefore, addresses what we consider to be the essential needs for successful implementation;

1. A clear rationale for the identification and selection of the correct technology and implementation partners

2. Precise analysis of the ASIS status and a benefit-related comparison to the TOBE future state

3. High levels of communication across all internal stakeholders that enable them to envisage their future role in the organisation and the programme (What is in it for me?), as well as the vision of the business in the future

4. Build an organisation for change that is not wholly reliant on external resources through the training of internal change agents.

5. Measuring the ASIS position accurately and, from there, setting target measures that are expected to be achieved due to the implementation of technology

6. Organisational transformation requires staff to be made aware and educated in the tools they can use to manage and influence the change required.

7. Toolkits to support the change must be flexible and tailored to the organisation’s culture and capability.

8. Visual communication of the change brought about by digital technologies Is vital to aid understanding and buy-in, enabling the capture of the business rules that orchestrate processes and the work instructions for future training, induction and process improvement.

Technology Invoked Change programme will emphasise the need for strategic thinking by asking senior executives to ‘take the lid off ‘their business and understand how it operates, particularly the interaction between end-to-end processes and departmental silos, measuring end-to-end performance rather than departmental and taking benefit assessment and monitoring seriously.

Our second thrust is to ensure senior management is confident to undertake and lead technology programmes by translating technical jargon into business-related impacts such as data quality and enrichment, process automation and Information-based decision-making. Adding to this capability will be the development of problem-solving and analysis across the business using tailored training suites based online. It will also enable staff to exercise their new skills within the project.

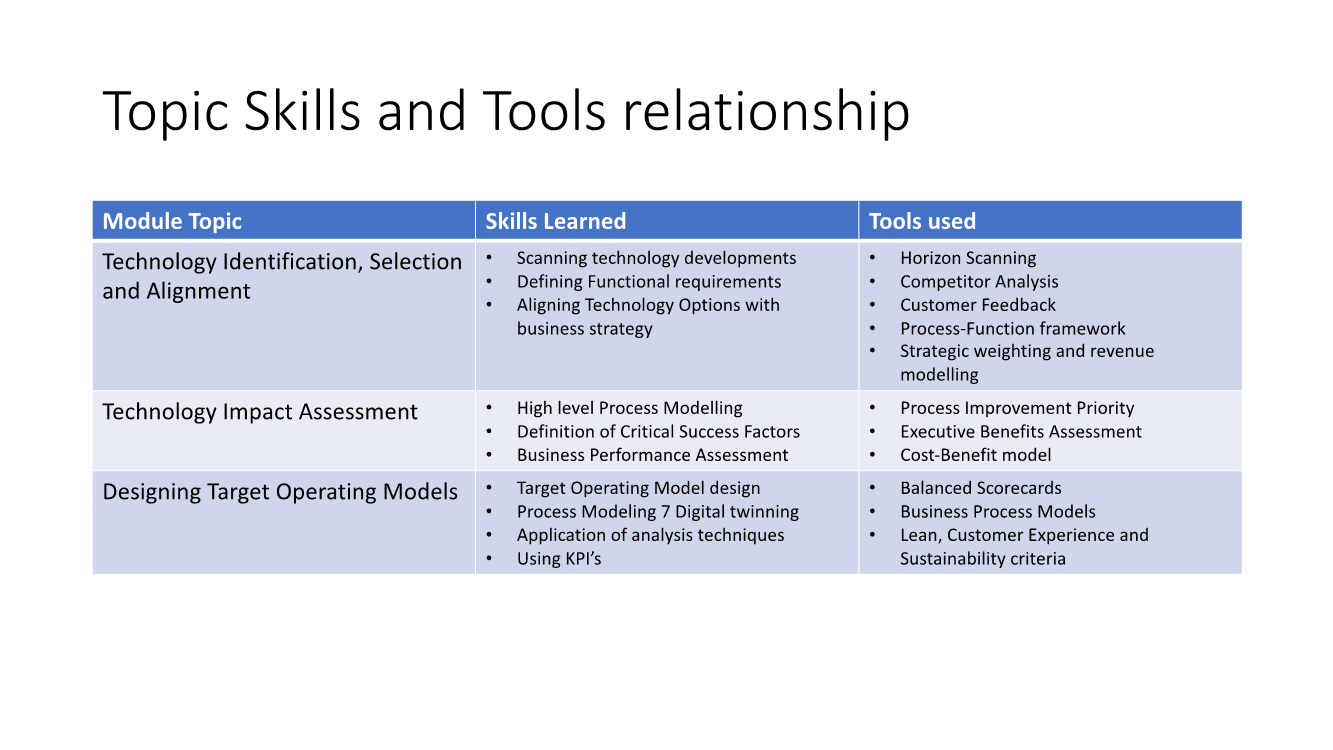

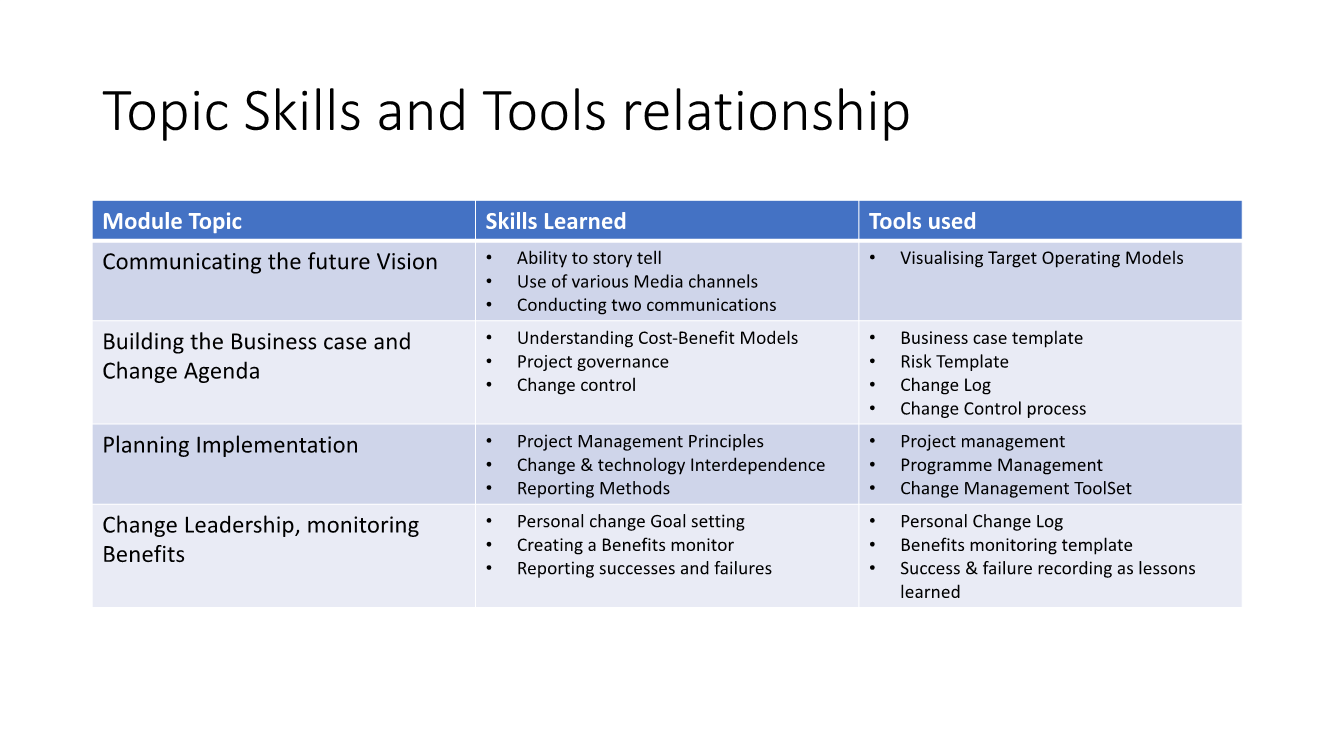

Over the years, several techniques and tools have been applied, some widely used, such as Project Management, and others honed or developed to address issues in projects such as Executive Benefits Assessment. We have built these into the following topics in the program;

• Technology Identification, selection and Alignment

• Technology Impact Assessment

• Designing Target Operating Model

• Communicating the future vision

• Building Business Case and Change agenda

• Planning implementation

• Assessing Change Leadership and monitoring benefits post implementation

Technology Invoked Change offers a flexible and structured approach to defining and successfully implementing technologies across a wide range of businesses over 13 modules. Combining tools for problem-solving analysis with visual methods to illustrate change impacts, organisational design, project management, and benefits assessment and monitoring.

Program Development

Technology Invoked Change is a framework which takes senior executives through a process to successfully manage change programmes driven by technology implementation. The framework can be applied across a wide range of industries providing senior executives the ability to manage projects that achieve bottom-line impact. The framework’s design reflects the building of skills and understanding so senior executives can confidently handle any programme and gain the benefits predicted.

The first four modules, therefore, address the history of technological development and the rate of change leading up to the present day; the identification of the correct technology and the ability to align this with strategic objectives; plus the introduction of visual process models to facilitate the design and validation of new business models and associated benefits.

Module three tackles the issues of technology leadership in both the ability to communicate the vision for the business and the staff and managing technical inputs during the selection of partners and project implementation.

Modules five, six and seven cover the comprehensive understanding of business models and processes, introducing the application of end-to-end processes and the creation of the Target Operating Models. We use the process models to explore the impact of lean techniques on streamlining processes by addressing Non-Value Added activity and duplication. During this module, we also address process design from the perspective of Customer Experience.

Having introduced the concept of end-to-end processes and the digital twin of the overall business model, the next module, six, explores how we manage these processes and the allocation of process owners and Key Performance Indicators for the redesigned processes. Also, referring back to the model and applying business roles analysis of work scope, decision making, and skills required will help to frame training programmes and job descriptions.

Finally, in this section, module seven discusses how the change agenda can be formulated and what actions need to be undertaken to address the change, from training to job transfers or the provision of mobile technology. During the change agenda module, executives can lay out the high-level functional requirements that the technology needs to provide.

The following three modules, eight, nine and ten, then take the senior executives through preparing for implementation, starting in module eight, which addresses how to make a robust technology selection in terms of functionality and the implementation partner.

Module nine looks at the business case’s structure and development, which should provide the rationale and justification for the new business model and transformation; identify the risks and the return on investment. Module ten pulls together the process work and, with the business model, helps to set up the Balanced Scorecard covering financial, customer, process and organisational capability areas.

Having committed to technology and partnering and defined the business performance expected, the subsequent two modules address plan development and management, integrating technology activity with change management. Discussing work stream leadership within the business and the frequency and honesty of reporting to minimise overruns.

The Final module tackles change Leadership and the skills required to pull this off. We emphasise that this is a combination of the ability to communicate the vision clearly and with commitment; this is best demonstrated through actions taken by senior managers to contribute to the change.

The programme is hands-on throughout and ideally based on a technology project that the business requires. This will bring to life the Business Process Models and Target Operating Models. Governance of the programme will require senior management involvement supported by operational resources seconded by the business. The programme will need a sponsor and be represented across all the functions within the company.

It is recommended that a Project Manager is appointed to manage the plan and some of the contributing documents, monitor progress and manage the target project team, which should be 6-10 people. For balance and to ensure we cover decision-making, it is also recommended that the senior stakeholder and operational managers are represented by each department. This will enable the new Business Model to be tested and validated across the business and adjusted as required through a change process.

This programme is split into two, with the selection, assessment and planning taking place in 9 months; the implementation planning phase will depend on the project chosen, which could be anything from another 3 to 6 months. The first nine months enable the senior management to gain knowledge and expertise in applying the proposed components and embedding them into BAU. The tools and techniques will be appropriate to large- and small-scale implementations templates to speed up the gathering and transmittal of information. The modelling techniques enable management to ‘try before they fly’ scenarios and speed the understanding of the opportunities to change.

Program Implementation

The programme is about understanding the activities required to manage the change and using a practical project to apply the knowledge and build expertise. The time between modules is for communicating with stakeholders, engaging a broader audience in the principles and outcomes and developing information to finalise deliverables.

The coaching time between modules should be used to help clarify any issues or validate the use of any templates. This coaching provides guidance and ensures that the work undertaken meets the needs. As some of the concepts will be new to the senior management team, they are anticipated to refine the thinking used within the module.

Modules one through seven covers how to prepare for a technology project, covering both personal capability and a structured process for selection, evaluation and business modelling.

Modules eight through twelve take the thinking and redesign of the business developed in the first eight modules and subsequently agreed upon by the broader company, producing a plan with the correct technology to implement. Having built a program and understanding the fundamental principles of management, the team is anticipated to complete the project in the following months, anything from 9 to 36 months, depending on the project’s complexity.

The programme is designed so that each module is delivered every four weeks; there will be opportunities to review materials ahead of time with additional resources. All the modules are aligned in a sequence that addresses the natural lifecycle of a technology-driven business transformation programme. Starting with Technology Identification, selection and Alignment, Technology Impact Assessment, Designing Target Operating Model, Communicating the future vision, Building Business Case and Change agenda, and Planning implementation. It is, therefore, essential that the project team remain the same throughout the training. Each module logically builds the knowledge base and informs the next deliverables and activities.

The overall objective of the four topics (Technology selection and Impact Assessment, Designing and communicating the future vision at corporate and personal levels, Planning and managing the implementation, and Assessing and monitoring benefits post-implementation) delivered through the 12 modules to ensure the organisation goes through the technology-driven change programme. There will be no need to reinvent the wheel or spend time creating templates during the program. Utilising the pre-defined templates and toolkits, you will focus purely on implementation. The Project team, during these phases, will be designing, brainstorming, analysing, testing, visioning and making decisions about process design, functionality, planning, and assessing impact. Only in the “doing” do we genuinely redefine our thinking and create options and scenarios of the future we desire. This program aims to be a discovery and experimentation journey that we hope the Project team will enjoy whilst learning new skills and methodologies.

Program Review

The programme review will be split into two the first after the change management plan is agreed upon, and the team can seek to understand and document the lessons learned and agree that the benefits monitoring process and targets are correctly set; the second stage will be done post-implementation, say 3 to 6 months into operation to see if benefits are flowing according to the plan and implementation has stabilised.

All modules are interlinked, and one cannot be delivered without the other. The sequence ensures that as knowledge develops and tools are applied, the team can assess their capability to define, plan, and deliver outcomes. Therefore, each module provides an element of review to reflect on progress, incorporating feedback and consolidation of requirements. In this process, at the beginning of each module, we will be looking back, looking forward and then deciding on actions that need to be taken in the present to realise the benefits.

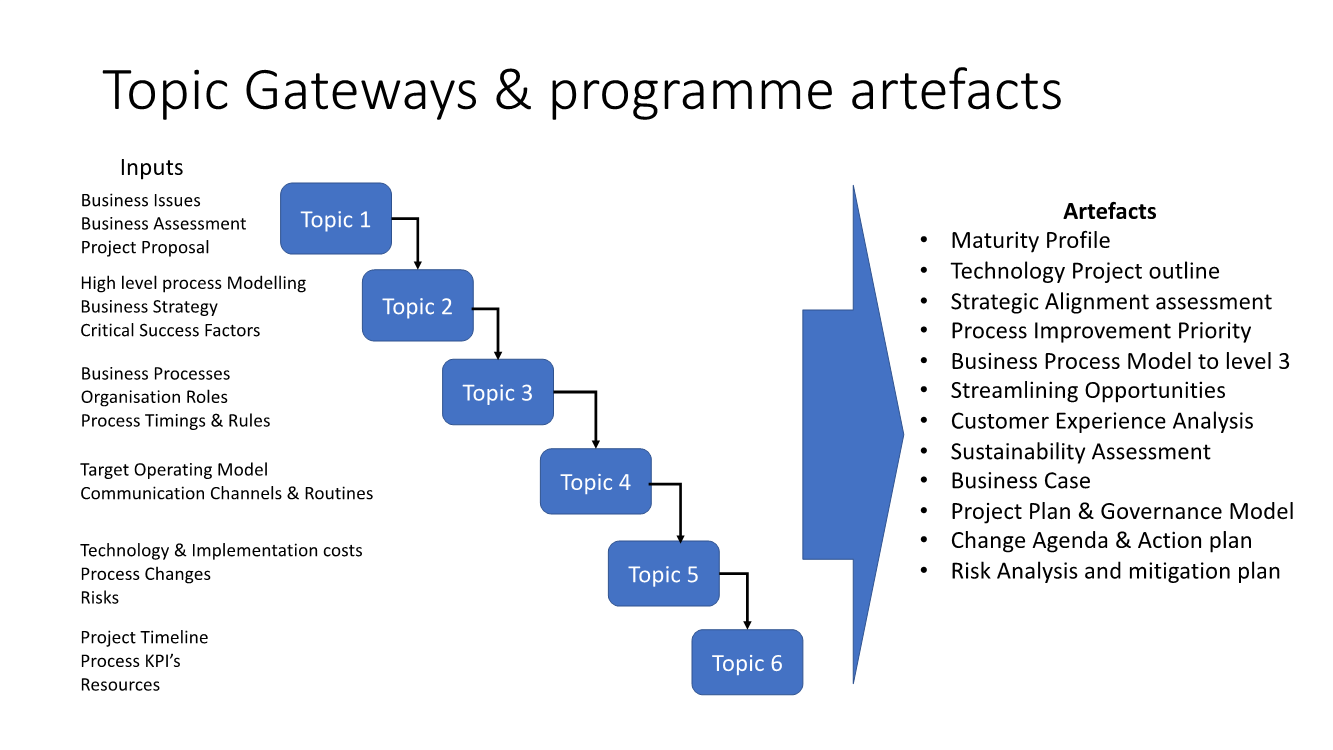

Additionally, in line with Product Development thinking, we will apply stage gate analysis at the end of each topic, the criteria will be presented, and a weighted score will be calculated. The sponsor is recommended to validate the set of standards, weighting and scoring mechanism. The topic gateways will be:

Topic 1: Technology Identification and selection criteria will include scanning technology options, aligning technology to strategic objectives and setting selection frameworks.

Topic 2: Technology Impact Assessment criteria will include process priority assessment with Critical Success Factors, process Performance Analysis and Executive Benefits Assessment.

Topic 3: Designing the target Operating Model criteria include process modelling, Lean and CX analysis, role design and process KPIs and ownership.

Topic 4: Communicating the vision criteria includes communication planning, storytelling, personal and corporate distinction in What is in it for me.

Topic 5: Building the Business case and Change agenda criteria will include the validity of implementation, strength of the change agenda, relationship to the technology chosen, and cost-benefit model.

Topic 6: Implementation Planning criteria include integration within the business and with external partners, the plan’s credibility based on resources available, progress reporting and the change control process.

Topic 7: Post-implementation relates to the final module and will assess the implementation progress and the change leadership’s quality. It will build up the lessons learned and ensure that the vital knowledge and tools are absorbed into BAU.

This series of training modules will provide a strong base for your business to manage any technology programme successfully.

Industries

This service is primarily available to the following industry sectors:

Automotive

Preamble

This covers major automotive manufacturers, specialist builders and designers, and Tier 1 and Tier 2 sub-assembly and component suppliers.

History

The automotive industry was one of the first to experience the impact of scientific management, starting with time studies and the balancing of workload across stations on an assembly line. The industry moved from vertically integrated across all disciplines to creating supply networks based on skill groups or capital assets.

Occupational Health and Safety – Automotive Industry – ASK EHS Blog. www.ask-ehs.com

In the 1970/the 80s, a Quality initiative started in the US became the foundation for a fundamental movement in the Japanese automakers move upwards into better quality, more extended warranties and into the premium brand sector. Branded initially as Total Quality Management TQM, this initiative spawned a complete approach and set of tools for managing processes to raise quality. As this approach matured, the techniques were grouped under the term ‘lean’, indicating the focus had broadened to embrace the waste within processes from transport, stock, unnecessary process and packaging, for example.

Alongside this manufacturing development, we had changes in design approach with the introduction of computer-aided design and resource management systems enabling better control of materials and labour across plants and throughout the supply chain. We have seen changes in materials with more emphasis on component weight leading to changes in manufacturing techniques and raw materials such as aluminium.

Customer expectations were driving the need for a greater choice of models and levels of finish, thereby increasing the numbers of components, assembly complexity, product definition and management and management of spares.

Current Position

Building on the need to lower costs in all aspects of vehicle design and make automakers have increased the use of digital technologies in design, leading the way on ‘digital twining’, enabling them to try before they fly with designs providing complete design packages to sub-assembly partners and shortening the concept to production cycle by 18-24 months. During this period, many automakers have extended their research and development into forms of motorsport such as Rallying and Formula 1. Both for the use of materials such as carbon Fibre for both body panels and suspension parts to energy recovery and storage systems now prevalent in Hybrid vehicles.

Cost reduction demanded the rationalisation of models and levels of trim. In models, the focus was on reducing the number of platforms used across a range, as the chassis is the most expensive element of a vehicle and can be easily clad in various body shapes. The Japanese addressed the trim issue by including all the possible alternatives on the car except for colour and interior finish; European manufacturers have started to reduce the number of options unless an explicit part of the brand, such as Rolls Royce or BMW, for example.

Digital technologies have replaced and enriched the driver experience, from satellite navigation to digital dashboards and driver aids.

During this period, the demise of the Petrol and diesel engines has been signalled, with 2030 seeming to be the target for many countries to stop selling vehicles powered by internal combustion engines. The alternative electric cars were led by Tesla, and now all major manufacturers have electric vehicles in their ranges. This transformation demands different materials, skills and products, namely batteries and electric motors.

Future Outlook

The core progression will be moving to electric vehicles and removing internal combustion engine assets being decommissioned. Alongside this change in the power train of cars, there are still many changes being introduced with technology. One of these is the increased move towards leasing and rental rather than ownership with the introduction of more effective customer management systems and the link to finance plans.

Materials will continue to evolve, and more carbon fibre and lightweight materials being introduced. But the most significant change will come through in-car entertainment and control systems; more significant levels of integration with personal mobile devices. More AI will become standard as the autonomy of vehicles will start to be reliable.

Capital Equipment

Preamble

This covers to design and building of Agricultural and Construction equipment.

History

The capital equipment industry was behind the automotive in the adoption of scientific methods in part due to the size of the final assemblies and, for some equipment, the genesis of the company from such as simple farm equipment such as JCB.

The Total Quality Management Initiative was also slower to grow, maybe due to volumes and the different customer expectations of the end product. This did mean that the tools and techniques were more readily available, but practitioners still needed to be a resource. Adapting the lean techniques from automotive industries required a greater focus on the component and sub-assembly size and weight. Assembly lines needed more space, and inter-operational Storage and movement were a significant consideration.

As with the automotive sector, we had changes in design approach with the introduction of computer-aided design and resource management systems enabling better control of materials and labour across plants and throughout the supply chain. Supply chain developments embraced some sub-assembly manufacturing, for example, cabs; here, we need sheet metal and interior design and finishing skills.

The market is dominated by players from the US, UK, Germany and Japan, with specialist manufacturers from the likes of Sweden, for example. There were only a few crossovers initially, but this inevitably grew as new models were developed. Additionally, as the construction industry was, a worldwide manufacturing expansion took place in countries where the machines were being used. In most cases, this also involved the Spares organisation and maybe Design Responsibility for local variants.

This then required distributed commercial and engineering system with a close coupling of spares stock. As significant capital assets, one of the critical elements in the sales process was the provision of financing through the manufacturer, and leasing became fashionable.

Current Position

Building on the need to lower costs in all aspects of machine design and build, manufacturers have increased the use of digital technologies in design, leading the way on ‘digital twining’, enabling them to try before they fly with designs providing complete design packages to sub-assembly partners and shortening the concept to the production cycle. There is still an increasing number of products as a combination of tools, traction methods and digital technologies have replaced and enriched the driver experience, from satellite navigation to digital dashboards and driver aids.

The movement towards onshoring has begun reversing the previous trend of design at home and manufacturing overseas. Subcontractors are requested to take on more work, increasing their skills and providing more complete sub-assemblies. This requires training and more control of the supply chain and engineering change control; plus, as they grow, the requirement for ‘lean’ practices grows, which more significant pressure on OEM to provide practitioners and training; again, digital technologies are stepping into this space with online training and certification and collaboration tools.

Future Outlook

Future trends will reverse some of the globalisation, demanding large-scale system changes to support onshoring. Greater focus will be paid to Sustainability within the supply chain and the maintenance of the vehicles; such remote preventative maintenance will reduce the number of disastrous failures, which in a construction environment can lead to huge impacts on project timelines and costs as other equipment and operating personnel are idle.

The pace of Change will also quicken in the move from electrical and mechanical disciplines to more mechatronic approaches and, therefore, different systems to support the greater integration of mechanical design elements and obviously more significant digital influences.

As leasing and capital costs increase, there is more requirement for vehicle security, even for sub-assemblies and tools, since the core vehicle can be more challenging to move.

Oil & Gas

Preamble

This covers mainly Support Industries to the major Oil Production companies, which cover the rig-building, Sub-Sea support such as diving and pipe-laying vessels, land plants or ethylene and Liquified Natural Gas.

History

The support industry for the early Oil company production was based around land-based drilling and pumping of Oil, manufacturing pumps, valves and pipes being the most prominent technologies. As a new industry, there was little embedded process or custom and practice, so as new equipment was introduced and problems arose, the solutions were developed on the spot. A simple vertical integration was in place to cover the early fractionating processes to separate the different oil types. The specialisms existed in the production companies for both up and downstream activities.

As the industry grew and the search for oil fields moved from only land-based to subsea more technologies and skills were required, which meant that the supply chain became more complex. Some specialisms existed only in the suppliers, such as high precision machining, Rig design and Build and Marine Engineering and Vessel management.

Oli spills from tankers also required ingenuity to restrict the damage and enable some salvaging of the natural world with oil skimming techniques.

Current Position

The market is very complex, with its trading structure with different Oil qualities dependent on the level of certain elements. The array of petrochemical products has become massive and fuels not only cars but chemical and plastics industries. As the complexity of markets products developed, so did the need for commercial control systems and more sophisticated methods of transport and Storage.

The complexity of the trading and manufacturing, and distribution structure, plus the expense of finding and exploiting reserves, means that there is little opportunity for market entrants, most picking up older or more difficult-to-exploit fields which require lower overheads to be profitable.

With the demand for greater responsibility for the impact on the climate, there is a need for cleaner fuels, better management of waste products such as gas and the reduction in types of single-use plastic.

Therefore, much of the focus is on chemical development, improvement in the internal combustion engine, and more effective carbon capture on fossil fuel operations. Profits from carbon are being channelled into renewables and the Storage of energy when a surplus is generated.

On the system’s front, large ERP systems dominate the space, and the most significant gain is in three key processes estimating, project management and accounting and material management/supply chain control. Though innovation is commonplace in up and downstream activities, it needs to be more prominent and accepted in the administrative areas.

Future Outlook

There are several divergent forces acting on the O&G sector, particularly between energy security, supply diversification and the transition towards low carbon. The majors in the upstream part of the supply chain have good balance sheets, so they can be asked to lead the accelerating and secure transition to low carbon. The US-style’ carrot’ approach may be more effective at driving innovation, and this will be seen in carbon capture and Storage, renewable fuels and hydrogen.

Pricing might have a significant influence on to change in focus to green hydrogen and Biomethane, for example, from blue hydrogen. Also in the mix is the food versus fuel debate that might eventually swing away from using land, mainly when carbon-positive natural features such as rainforests are felled for fuel production.

Energy security will also drive different types of innovation and technologies, such as creating ‘cleaner’ natural gas to enable it to bridge the energy transition.

The demands on the supply chain continue to grow with significant growth in vessels such as LNG carriers and gas rigs; the demand on infrastructure is also increasing (pipelines, Storage and biofuel refineries) and other technology (carbon capture materials, electrolysers and fuel cells).

Healthcare UK

Preamble

Healthcare for every nation has a different complexion, with the UK being home to the only national service across the developed world. This is now blended with private provision, but the core of services is still provided ‘free at the point of delivery’.

History

The medical profession is probably one of the oldest in existence. Such has progressed through several delivery models, with science and technology playing a larger part in the services offered. In the UK, the care model is based on General Practitioners and Practice Nurses operating through local surgeries, Nurses, Consultants and Surgeons operating out of Hospitals; all this is also supported through social care provision in the community. Early manifestations included home visits and the concept of a family doctor who managed the health across the generations.

For more intensive care and specialisms, hospitals were developed and associated with these centres for managing trauma which the UK called Accident and Emergency Departments. As specialisms grow, the organisation becomes more and more siloed, and the population growth has driven up the need for front-line care and the level of bureaucracy.

Several management variations have been applied, aiming to recognise and provide for different people demographics across the UK and to place responsibility for delivery closer to that demographic. Progress in care has led to us living longer, increasing the demand alongside new developments in care for diseases, ageing and conception.

Patient records have always been vital to fast and accurate treatment. As treatment options become more complex across different disciplines, so do the issues associated with sharing that information.

Current Position

Aside from the technological developments in surgery and less invasive forms of intervention, the focus is on digitisation. Driven most recently in the aftermath of the COVID pandemic and the resultant backlog of patients, there has been a sea change in the number of primary care processes from repeat prescriptions to GP appointments and the ability for a patient to see the fundamentals of their health record online. For example, in 2021, Online consultations with GPs topped 360,000. In addition to reducing time for the GP, they have also impacted the Net Zero carbon reduction removing an estimated 386 tonnes of carbon emissions.

Change is still prolonged, however, and to try and drive this forward faster, the government has mandated that all Trust, the management structure for managing care delivery, must;

• Identify a senior Officer responsible for digital

• Make sharing data records a priority.

• Increase digital literacy across all staff levels

• Enable analytics across their multiple systems

• Provide achievable rod maps for digital transformation