Operational Excellence

The Appleton Greene Corporate Training Program (CTP) for Operational Excellence is provided by Mr. Muenzing Certified Learning Provider (CLP). Program Specifications: Monthly cost USD$2,500.00; Monthly Workshops 6 hours; Monthly Support 4 hours; Program Duration 36 months; Program orders subject to ongoing availability.

Personal Profile

Meet Mr. Muenzing: Visionary Leader in Lean Transformation and Turnaround Management

Mr. Muenzing is a distinguished authority in lean transformation and turnaround management, amassing three decades of executive and advisory roles in management consulting. As President of Leanmap, a specialized management consulting boutique, he empowers manufacturing, technology, and service enterprises to elevate performance and gain sustainable competitive advantages through world-class operations.

Driven by innovation and systems thinking, he earned a Bachelor’s in Electrical Engineering (BSEE) from FHD in Germany. He swiftly excelled in the Telecom industry, pioneering three groundbreaking innovations for base stations that showcased his visionary mindset and exceptional problem-solving skills. Recognizing the need for business acumen, he pursued a Master’s in Business Administration (MBA) from NSU in the USA, laying the foundation for his transformative leadership.

Throughout his illustrious career, he revitalized struggling companies and enhanced successful ones to reach world-class status. With extensive expertise in operations, product development, and business consulting, he offers diverse insights to clients. An accomplished author, he penned “The 20 Keys to World-Class Operations” and “From Chaos to Control.” He also shares his knowledge through speaking engagements on innovation, lean transformation, cost reduction, and quality excellence.

Mr. Muenzing’s expertise has been sought by over 150 client-organizations across 40 countries, driving operations toward world-class benchmarks. These transformations yielded financial benefits surpassing $500 million from top-10 programs, with an average return on investment (ROI) of 12x across all initiatives. With a remarkable 96% repeat clientele rate, his enduring impact is evident, leaving a lasting impression on clients. Key engagements include:

1. Leading Automotive Supplier (Sweden):

As an Industrialization Expert, led the Engineering team to enhance time-to-market (TTM), quality and delivery performance to major automotive customers. His systematic improvements in technology readiness and process capability led to a doubling of launch successes at the start of production (SOP) and an astounding 8x reduction in defects per unit (DPU) in just six months.

2. Major Semiconductor Fab (USA):

In the role of Operations Expert, spearheaded a transformation initiative to optimize cost-per-move (CPM) through adaptive maintenance, systematic problem analysis, and disciplined root-cause elimination. Coached 10 Advanced Module Engineering (AME) teams during the transition phase, realizing 326 projects that delivered $118 million cost savings (run rate) in the first year.

3. Pharmaceutical Operation (France):

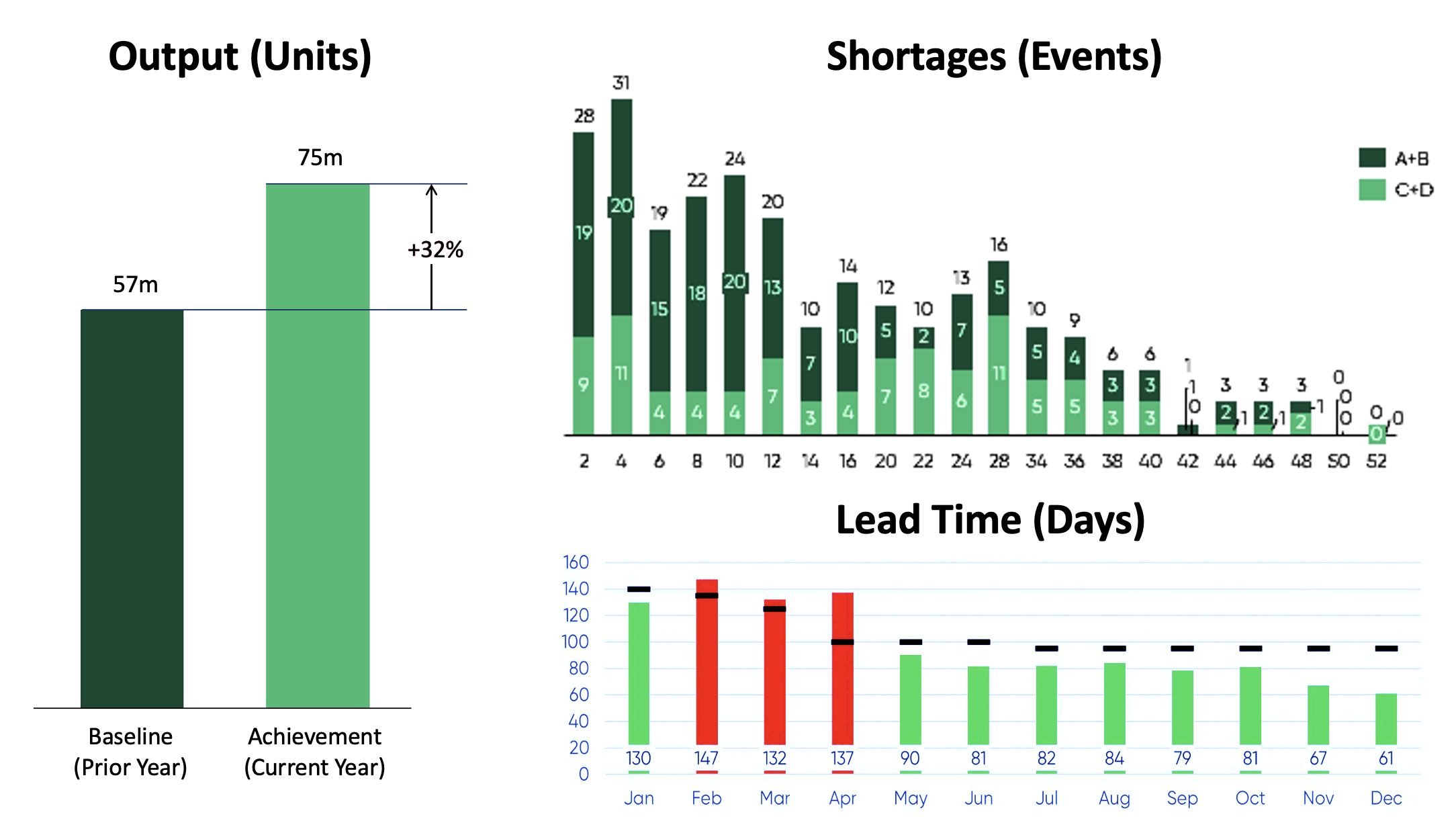

As Operations Expert, led the factory turnaround with focus on operational efficiency (OEE) to ensure stable patient supply. As a result, doubled efficiency within 12 months, increased throughput 32% without spending capital, cleared backlog, reduced deviations by 25%, and shortened lead time by nearly 50%, while maturating the site towards Operational Excellence.

4. Largest Marine Electronics Company (Mexico):

As the Interim Operations Executive, he orchestrated a Manufacturing Turnaround that doubled throughput to meet customer demand. Through systematic defect reduction, design for manufacturability (DFM), and strict flow management, he achieved a 44% reduction in labor hours, 53% reduction in footprint, 94% reduction in inventory, and 66% reduction in rework in just one year.

5. Leading Flavor and Fragrance Company (Switzerland):

In the capacity of Global Leader for Lean and Operational Excellence, he spearheaded a Lean Transformation Initiative across 20 global flavor-production facilities. His efforts yielded over 400 improvement ventures, adding CHF 36 million to the company’s profits in just 3 years, while attaining a competitive edge by elevating both quality and delivery standards..

6. Largest Appliance Factory (China):

As the Integration Manager, he successfully merged two large assembly plants in Guangdong into one. Through streamlining material flow, balancing workload, and right-sizing manning, he reduced shortages and late deliveries by 50%, lowered on-hand inventories from 46 to 18 days, and added $20 million annual manufacturing capacity to meet forecasted demand.

Mr. Muenzing exemplifies impactful leadership through visionary expertise, driving lasting transformations by fostering world-class quality, speed, and efficiency. His consistent record of sustainable bottom-line growth and unwavering commitment to continuous improvement mark him as a global driving force behind corporate success. For anyone seeking to navigate their way to operational excellence, Mr. Muenzing is the expert to turn to. With his visionary leadership, profound expertise, and exceptional ability to create lasting improvements, he continues to shape the future of organizations across the globe.

To request further information about Mr. Muenzing through Appleton Greene, please Click Here.

(CLP) Programs

Appleton Greene corporate training programs are all process-driven. They are used as vehicles to implement tangible business processes within clients’ organizations, together with training, support and facilitation during the use of these processes. Corporate training programs are therefore implemented over a sustainable period of time, that is to say, between 1 year (incorporating 12 monthly workshops), and 4 years (incorporating 48 monthly workshops). Your program information guide will specify how long each program takes to complete. Each monthly workshop takes 6 hours to implement and can be undertaken either on the client’s premises, an Appleton Greene serviced office, or online via the internet. This enables clients to implement each part of their business process, before moving onto the next stage of the program and enables employees to plan their study time around their current work commitments. The result is far greater program benefit, over a more sustainable period of time and a significantly improved return on investment.

Appleton Greene uses standard and bespoke corporate training programs as vessels to transfer business process improvement knowledge into the heart of our clients’ organizations. Each individual program focuses upon the implementation of a specific business process, which enables clients to easily quantify their return on investment. There are hundreds of established Appleton Greene corporate training products now available to clients within customer services, e-business, finance, globalization, human resources, information technology, legal, management, marketing and production. It does not matter whether a client’s employees are located within one office, or an unlimited number of international offices, we can still bring them together to learn and implement specific business processes collectively. Our approach to global localization enables us to provide clients with a truly international service with that all important personal touch. Appleton Greene corporate training programs can be provided virtually or locally and they are all unique in that they individually focus upon a specific business function. All (CLP) programs are implemented over a sustainable period of time, usually between 1-4 years, incorporating 12-48 monthly workshops and professional support is consistently provided during this time by qualified learning providers and where appropriate, by Accredited Consultants.

Executive Summary

Unlocking Competitive Advantage with High-Performing Operations

Operational Excellence

Purpose and Principles

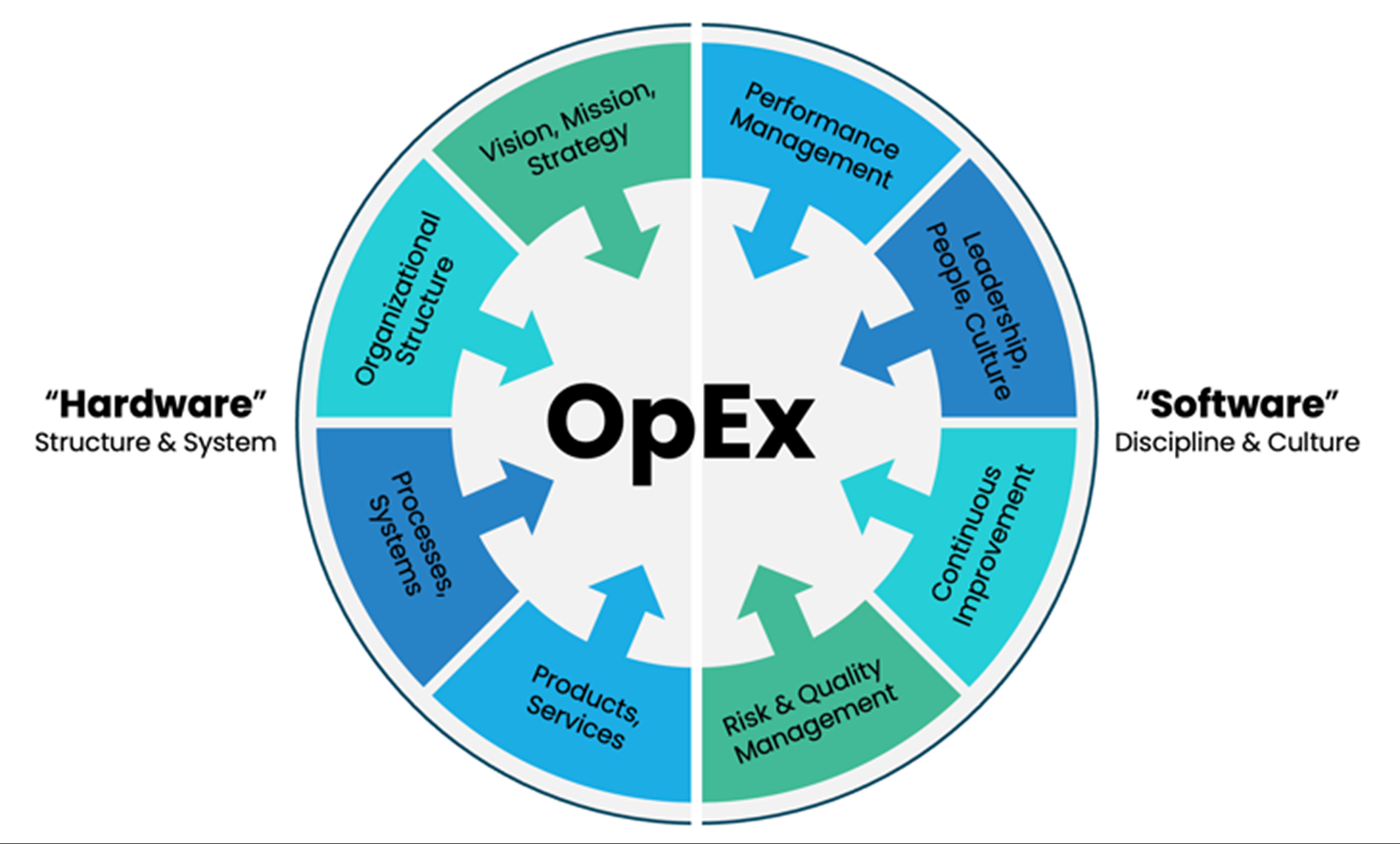

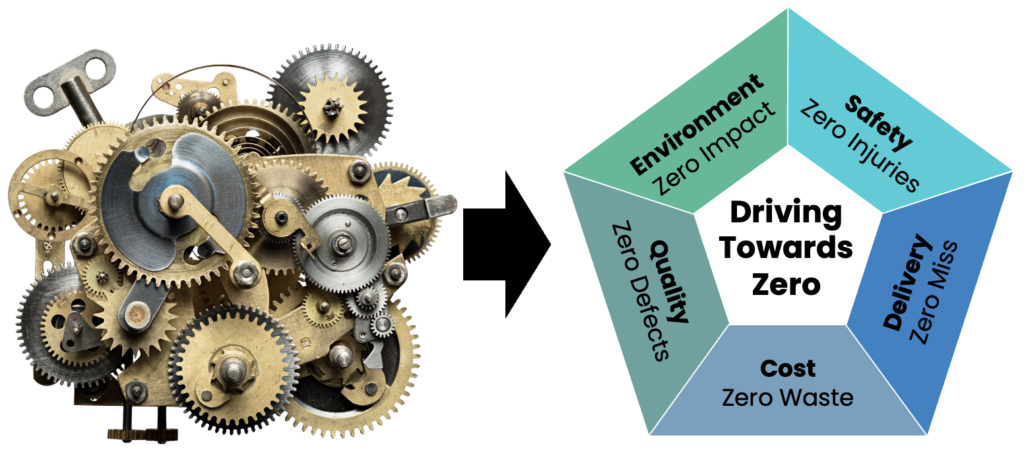

Operational Excellence (OpEx) plays a pivotal role in enhancing a business’s competitiveness by elevating efficiency, reducing expenses, enhancing quality, and fostering innovation. By streamlining processes and promptly addressing customer demands, companies gain a significant advantage in the fiercely competitive market. Moreover, OpEx also helps in mitigating risks and fortifying resilience, ensuring sustained success irrespective of whether a company is involved in producing things, handling transactions, or caring about people.

Unleashing the Power of Continuous Improvement

OpEx is more than a buzzword; it’s a philosophy embraced by leading organizations to drive consistency, growth, and sustainability through unwavering commitment to excellence. By integrating sustainable change into their culture and practices, companies achieve operational breakthroughs. Key principles include quality commitment, leadership engagement, employee involvement, seamless teamwork, strategic focus, customer value, agile execution, process excellence, and vision alignment. Embracing these elements unlocks extraordinary short-term results and fosters a sustainable competitive advantage through OpEx.

Teamwork and Culture

Effective teamwork is imperative for operational excellence. Organizations must foster a culture of collaboration, where individuals work synergistically towards common goals. This entails fostering open communication, sharing knowledge, and encouraging cross-functional collaboration. A culture of continuous improvement must permeate the organization, empowering employees to proactively identify opportunities for enhancement and take ownership of their work.

Committed Leadership and Performance Management

Leadership plays a pivotal role in driving operational excellence. Committed leaders provide a clear vision, set high expectations, and lead by example in their dedication to ongoing improvement. They establish robust performance management systems that align individual and team goals with the organization’s overarching objectives. Through regular feedback, coaching, and recognition, leaders inspire employees to strive for excellence and actively contribute to the organization’s success.

Continuous Improvement and Process Excellence

Continuous improvement lies at the heart of operational excellence. Organizations must establish structured methodologies such as Agile Lean Six Sigma (ALSS) to systematically identify and eliminate waste, variability, and complexity, while streamlining processes and drive efficiency. By empowering employees to suggest improvements and providing them with the necessary tools and resources, organizations tap into a valuable wellspring of knowledge and innovation.

Risk and Quality Management

Operational excellence demands an unwavering focus on risk and quality management. Organizations must proactively identify and mitigate potential risks to ensure seamless operations. Quality management practices, including robust standards, quality at the source, stringent controls, regular audits, and a strong customer feedback loop, enable organizations to consistently deliver reliable products and services that meet or exceed customer expectations.

Organizational Structure and Alignment

An effective organizational structure is vital for operational excellence, facilitating clear communication channels, streamlined decision-making processes, and individual accountability. Departments and teams must be aligned to work seamlessly together, breaking down silos and fostering cross-functional collaboration. Furthermore, the organizational structure must be closely aligned with the organization’s vision and mission, ensuring that all efforts contribute cohesively to the overarching strategic goals.

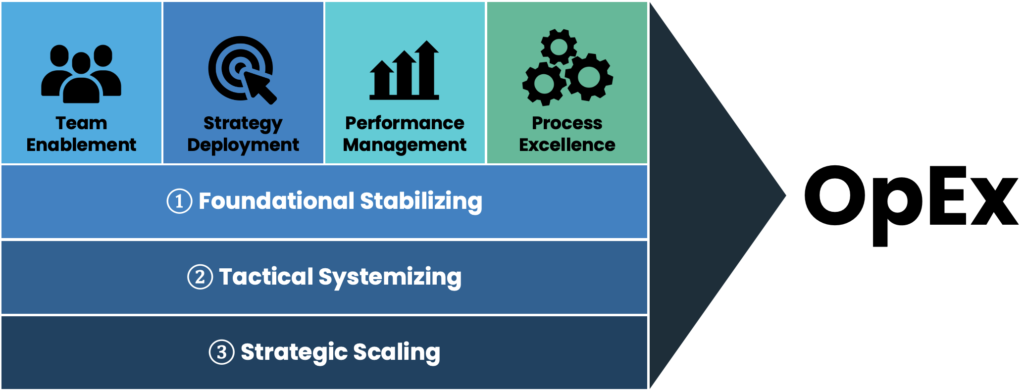

The Four Pillars

Team enablement, strategy deployment, performance management, and process excellence form the bedrock of driving excellence in operations. Team enablement fosters a collaborative culture, inspiring innovation and continuous improvement. Strategy deployment aligns efforts with the overall vision, ensuring goals resonate at every level. Performance management provides feedback and motivation for excellence. Process excellence streamlines operations, minimizing waste, and enhancing customer satisfaction. Together, these pillars empower organizations to excel, adapt, and thrive in today’s competitive landscape.

Embracing Excellence

Wholeheartedly adopting the specific elements of OpEx establishes a robust foundation for long-term success. Operational excellence empowers organizations to streamline processes, provide exceptional value to customers, proactively address risks, and swiftly adapt to evolving market conditions. By striving for excellence, organizations can set themselves apart, foster sustainable growth, and sustain a competitive edge in today’s dynamic business environment. OpEx transcends being a mere buzzword; it is the pathway to lasting success.

Overcoming Barriers

Pursuing OpEx demands a mindset and cultural shift, but not all companies prioritize it, leading to short-term gains at the expense of long-term benefits. Some lack resources or expertise, and others see it as an operational issue rather than a strategic one. Without a clear understanding and commitment to it, companies miss out on opportunities for growth and competitiveness. To take advantage of OpEx, we will now look at its history and its potential to improve business performance in any manufacturing or service operation.

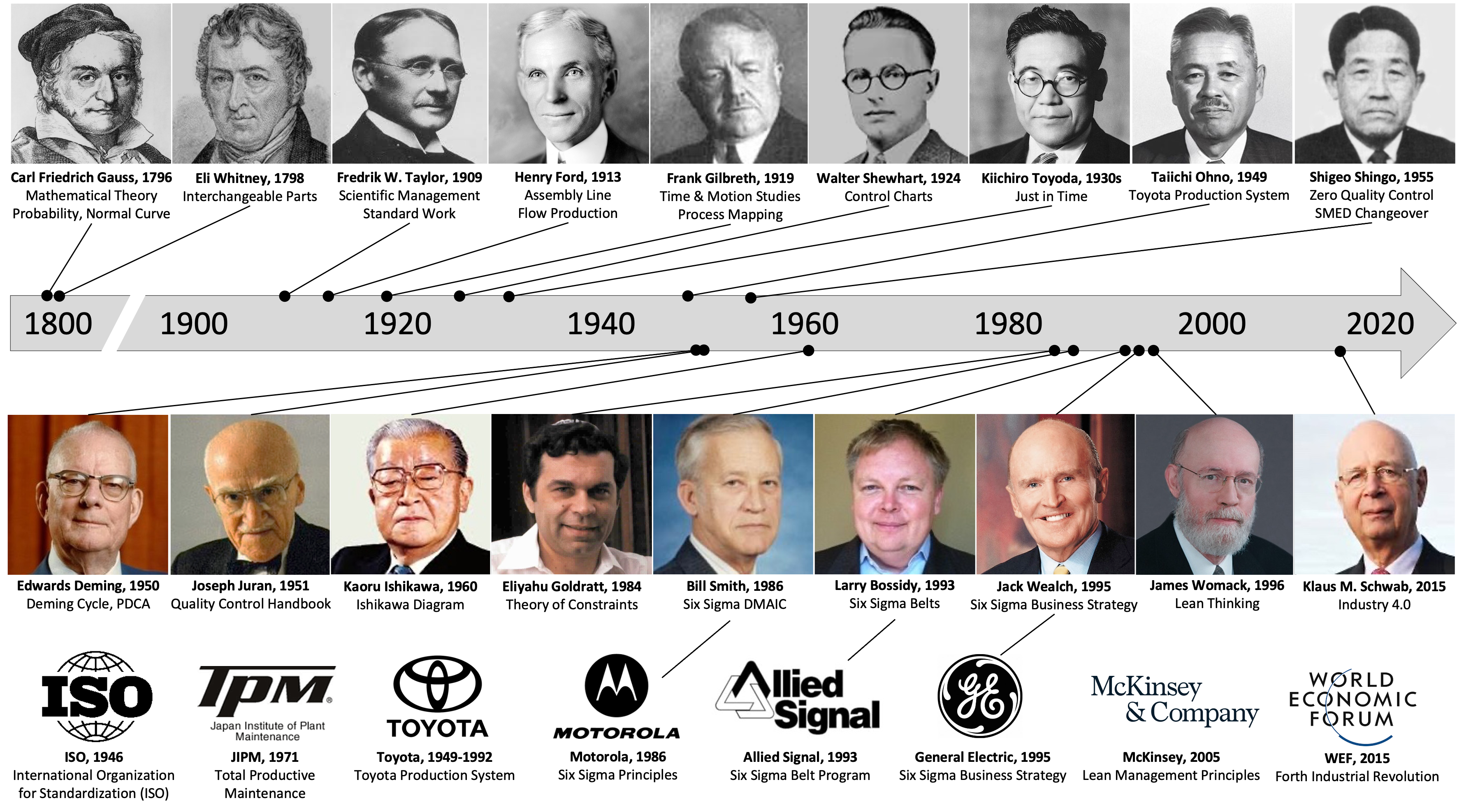

Pioneers and History

The concept of OpEx has many fathers; it evolved over time as organizations have sought to improve their operations and drive greater efficiency and productivity. The history of OpEx can be traced back to the early 20th century when organizations began to focus on standardizing processes to drive greater consistency while reducing waste, variability, and unevenness – the 3 great losses.

Prior to industrialization, craftsmen were responsible for overseeing every aspect of production or service, leading to difficulties such as fluctuating results, inconsistent output, and quality dependent on individual skills, as illustrated by the machine shop example below. However, OpEx revolutionized these practices, enhancing efficiency and reliability across all crafts and industries.

The start of industrialization brought a transformative period in history, shifting from traditional craftsmanship to mechanized production. Key changes included specialized tasks at workstations, enhancing efficiency and productivity. Standardization ensured uniform quality, revolutionizing manufacturing, and paving the way for mass production and the modern industrial era.

One of the pioneers of the OpEx movement was Henry Ford, who implemented the assembly line process in his automobile factory in the early 1900s. This revolutionary process allowed Ford to produce cars more quickly and at a lower cost, ultimately making automobiles more accessible to the public.

During World War II, the Japanese developed the Toyota Production System (TPS) as a response to the scarcity of resources and the need for greater efficiency. The TPS emphasized the elimination of waste, continuous improvement, and a focus on delivering value to customers. This system became the foundation of what is now known as Lean Manufacturing.

In the 1980s, the Total Quality Management (TQM) movement gained popularity in the United States. TQM focused on improving quality by involving all employees in the process, and it also emphasized the importance of customer satisfaction.

In the 1990s, Six Sigma was developed by Motorola to improve quality and reduce defects in manufacturing processes. Six Sigma uses statistical methods to identify and eliminate variations in processes, resulting in greater consistency and quality.

In the early 2000s, the OpEx movement began to shift away from a focus solely on manufacturing and into other areas of business, such as healthcare, banking, education, hospitality, and service industries. This broader approach to OpEx emphasized the importance of process improvement in all aspects of a business, including customer service, finance, and human resources.

Today, virtually all leading companies have made operational excellence part of their strategies for improving agility and productivity. Companies across industries, from manufacturing to healthcare to finance, have adopted OpEx principles to drive continuous improvement and create a culture of excellence.

In conclusion, the history of OpEx is a story of organizations seeking to improve their operations through a variety of methodologies and approaches, which includes Lean, Agile, and Six Sigma. Although the specific methods and tools have evolved over time, the goal of OpEx remains the same: to systematically increase agility, efficiency, productivity, and customer satisfaction by continuously improving processes without limiting itself to the use of a single methodology or toolbox.

Current Position

Operational Excellence (OpEx) has become a well-established management philosophy and strategy that aims to improve business processes and systems. Its popularity has been growing in the last few decades, with many organizations adopting it to enhance their agility, efficiency, productivity, quality, and customer satisfaction.

Today, OpEx is widely used in various industries, including manufacturing, healthcare, finance, and services. Many organizations have made it central to their strategy, and methodologies such as Lean, Agile, Six Sigma, TQM, and CI have become popular frameworks to implement OpEx. The adoption of OpEx has led to significant improvements in businesses, making them more competitive, regardless in which sector or region they operate. Even small companies in emerging markets have successfully deployed OpEx principles in their operation, such as a small food-shop in Mexico is using a bicycle rim to hold customer orders in the sequence they are received and synchronize the restaurant with the kitchen. One turn of the rim means that all customers have been served, which must be kept under five minutes to fulfill the service promise and keep their customers happy.

Despite its numerous benefits, deploying OpEx can be challenging for organizations. One of the significant hurdles is resistance to change. Implementing OpEx requires significant changes to existing processes and systems, which can lead to resistance from employees who are comfortable with the status quo. This challenge can be overcome by involving employees in the deployment process, providing them with the necessary training and support to help them adapt to the new systems and processes. OpEx formalizes processes and highlights problems, but not everyone endorses such transparency – usually only performers do.

Another challenge is the significant investment required in training, technology, and infrastructure. This can be a barrier for organizations operating in firefighting mode, where immediate issues take precedence over long-term investments. However, investing in OpEx can bring significant long-term benefits, including increased productivity, improved quality, and profitability. Therefore, it is always critical to take a longer-term perspective and look not only at the direct cost savings, but also at the increased market potential from increased agility, responding faster to customer needs than competitors do.

![]()

Organizations that have successfully implemented OpEx have realized many benefits. For instance, it has improved employee engagement and motivation by empowering employees to identify and solve problems in their work processes. This approach contrasts with a command-and-control style, where employees feel driven and controlled by the system. OpEx has also led to increased operational agility and efficiency, reducing lead times, costs, and increasing revenue, which has ultimately improved the bottom line. From my personal experience, most employees support OpEx once they have experienced how it works, and how it helps them to perform their tasks better and faster.

In conclusion, OpEx is a management philosophy and strategy that has become widely recognized across various industries. While deploying OpEx comes with challenges such as resistance to change and significant investments, the benefits realized by organizations that successfully implement it are numerous. By improving productivity, reducing waste, enhancing quality, and increasing profitability, OpEx helps organizations stay competitive in a rapidly changing global marketplace. It is not surprising that most organizations that adopt OpEx never look back, but rather increase the scope and scale of the program to tackle an even greater part of their value chain, pursuing Business Excellence by additionally including commercial, innovation, finance.

Key Questions

To successfully initiate the OpEx journey, it is helpful to assess the current situation by answering the following 10 key questions:

1. Condition: Is everything in order, and is everyone satisfied with the current state of affairs?

2. Problem: What specific problem needs to be solved, what goal must be achieved, and what gap requires closing?

3. Effects: What benefits will be realized if the problem is solved, and what consequences might arise if it is ignored?

4. Leadership: Has a clear vision been established, indicating where the team should be heading and why?

5. Alignment: Is there a shared unity within the team concerning the direction, purpose, and approach?

6. Resourcing: Are sufficient time, staff, and budget allocated to ensure a successful outcome?

7. Plan: Is there a well-defined roadmap in place, complete with milestones and clear responsibilities?

8. Skills: Are team members adequately trained and capable of effectively executing the program?

9. Incentives: Is there a compelling reason for everyone to actively engage and embrace change?

10. Communication: Are all team members well-informed, enabling them to actively participate and contribute?

The Operational Excellence program will systematically address all 10 points to bring your team and operation to the next level.

Future Outlook

As a business management philosophy and strategy, Operational Excellence (OpEx) aims to continuously improve processes and systems to achieve greater agility, efficiency, productivity, quality, and customer satisfaction. It has been a cornerstone of modern business practices for decades, and its importance is only increasing in today’s hyper-competitive and constantly evolving marketplace. In this article, we will examine the outlook of Operational Excellence and explore its potential impact on businesses and industries.

Digitalization

One of the key trends driving the future of operational excellence is digitalization. The proliferation of digital technologies has transformed the way businesses operate, and OpEx is no exception. With the advent of artificial intelligence, machine learning, data analytics, and the internet of things (IOT), businesses now have unprecedented access to data and insights that can help them optimize their operations. This data-driven approach to OpEx is expected to become even more widespread in the future, as more and more businesses leverage digital tools to gain a competitive advantage. Even small businesses today can take advantage of Digital-OpEx by using free, off-the-shelf tools, such as GoogleSheets, connected to wireless sensors linked to cameras that use intelligent image analysis and pattern recognition to streamline processes and manage performance.

Sustainability

Another trend that is shaping the future of Operational Excellence. As consumers become increasingly concerned about environmental and social issues, businesses are under pressure to operate in a more sustainable and responsible manner. OpEx can help companies achieve this by identifying and eliminating waste, reducing energy consumption, and improving the efficiency of their operations. In the future, we can expect to see a greater emphasis on environmental, social, and governance (ESG) aspects as core components of OpEx.

Adaptation

The rise of agile and flexible work practices is another trend that is likely to impact the future of Operational Excellence. As remote work becomes more common and businesses seek to become more adaptable to changing market conditions, OpEx will need to evolve to accommodate these new ways of working, supporting capacity-resource planning (CRP) and skill-building and load leveling of the workforce. This may involve adopting more Agile and Lean methodologies, and investing in digital tools that facilitate collaboration and remote work.

Technology

The future of operational excellence will be profoundly influenced by an array of ongoing technological advancements. Artificial Intelligence (AI) and Machine Learning (ML) will play a pivotal role by enhancing data analysis, predictive maintenance, and process optimization, enabling data-driven decision-making and streamlined operations. Concurrently, the Internet of Things (IoT) will provide real-time insights into various operational aspects like equipment performance, supply chain logistics, and inventory management, facilitating proactive maintenance and improved productivity. Robotic Process Automation (RPA) will further revolutionize operational excellence by automating repetitive tasks with software robots, reducing errors, and freeing up resources for more strategic activities, resulting in increased efficiency and cost savings. Leveraging Big Data and Analytics will empower companies to optimize operations across various areas, from supply chain management to customer service. Cloud Computing will play a significant role in implementing OpEx initiatives across multiple locations, fostering real-time collaboration, scalability, flexibility, and accessibility. Blockchain technology will enhance transparency and trust in supply chain operations, ensuring the traceability and authenticity of products and transactions. Additionally, Augmented Reality (AR) and Virtual Reality (VR) will be pivotal in employee training, visualizing complex processes, and efficient troubleshooting, thereby fostering faster learning and problem-solving. The emergence of 5G+ Connectivity will support real-time data transmission, facilitating quicker decision-making and remote monitoring of operations. Moreover, the integration of Autonomous Vehicles and Drones will optimize transportation and logistics, leading to reduced delivery times and increased overall efficiency. The concept of Digital Twins, creating virtual replicas of physical assets or processes, will enable simulations, analysis, and optimization without disrupting actual operations. Effectively incorporating these technological advancements into their operations will provide businesses with a competitive edge, fundamentally transforming operational excellence and positioning them for future success.

Conclusion

As we look ahead to the future of operational excellence, it is important to remember that this is not just a buzzword or a passing trend. It is a philosophy that has stood the test of time and has helped countless businesses achieve breakthrough objectives, massive productivity gains, and sustainable success. Whether it is through digitalization, sustainability, technology, or some other means, the future of OpEx is bright, and businesses that embrace this philosophy will be well positioned to thrive in the years to come. The picture below shows a team in Sao Paulo, Brazil, celebrating their journey to become regional OpEx champions. This is a testament to the potential and rewards that await those who use Operational Excellence in their endeavors to drive performance and advance careers.

Curriculum

Operational Excellence – Part 1 – Year 1 – Foundational

- Part 1 Month 1 Program Charter

- Part 1 Month 2 Strategic Alignment

- Part 1 Month 3 Problem Statement

- Part 1 Month 4 Causal Analysis

- Part 1 Month 5 Solution Development

- Part 1 Month 6 Pilot Study

- Part 1 Month 7 Solution Roadmap

- Part 1 Month 8 Capability Building

- Part 1 Month 9 Solution Implementation

- Part 1 Month 10 Solution Standard

- Part 1 Month 11 Impact Assessment

- Part 1 Month 12 Learning Leverage

Operational Excellence – Part 2 – Year 2 – Tactical

- Part 2 Month 1 Process House

- Part 2 Month 2 Target Conditions

- Part 2 Month 3 Digital Twin

- Part 2 Month 4 Lean Application

- Part 2 Month 5 Six Sigma Application

- Part 2 Month 6 Agile Application

- Part 2 Month 7 Portfolio Optimization

- Part 2 Month 8 Workflow Digitalization

- Part 2 Month 9 Digital Standards

- Part 2 Month 10 Target Organization

- Part 2 Month 11 Management System

- Part 2 Month 12 Execution Engine

Operational Excellence – Part 3 – Year 3 – Strategic

- Part 3 Month 1 Strategic Anchor

- Part 3 Month 2 Strategic Planning

- Part 3 Month 3 Strategic Adaptation

- Part 3 Month 4 Experience Design

- Part 3 Month 5 Innovation Strategy

- Part 3 Month 6 Technology Roadmap

- Part 3 Month 7 Resource Allocation

- Part 3 Month 8 Institutional Capabilities

- Part 3 Month 9 Change Leadership

- Part 3 Month 10 Governance Integration

- Part 3 Month 11 Risk Mitigation

- Part 3 Month 12 Corporate Culture

Program Objectives

OpEx Preparation: The 10 key questions to assess readiness.

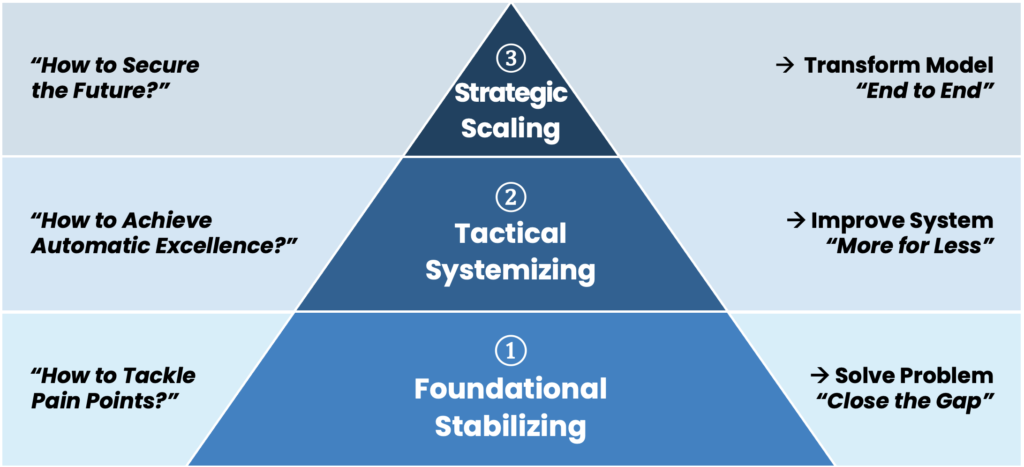

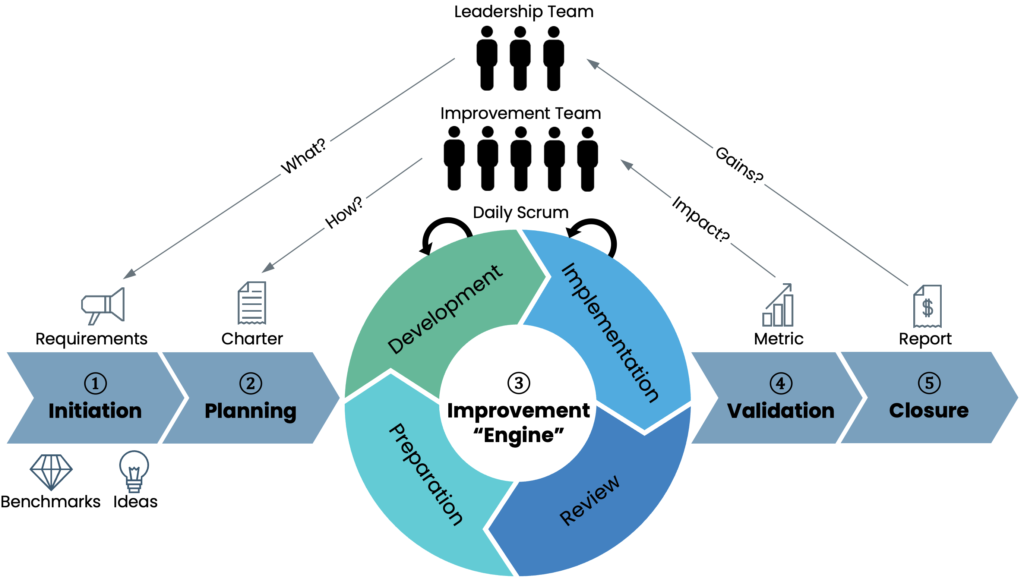

The following list represents the Key Program Objectives (KPO) for the Appleton Greene Operational Excellence corporate training program. The program is structured into three parts – Foundational, Tactical, Strategic – and conducted over a three-year period. This systematic approach empowers participants to fully grasp the content, implement the principles in real-world scenarios, and seamlessly integrate their newly acquired expertise into their daily operations, leading to tangible and measurable outcomes.

Operational Excellence – Part 1 – Year 1 – Foundational

- Part 1 Month 1 Program Charter – Prepare for a transformative journey toward operational excellence. As with any improvement program, establishing a clear structure is essential to overcoming challenges and effectively capitalizing on opportunities. Without a clearly defined program charter, initiatives can easily lose direction, encounter scope creep and resource cannibalization, lead to misunderstandings, and ultimately fail to achieve their objectives. Recognizing the significance of a solid program charter establishes the foundation for a successful program launch and marks the beginning of our journey. In this inaugural training module, you will gain valuable insights and practical strategies to drive your organization towards operational excellence. Discover the driving force behind pursuing excellence, craft a compelling vision statement, and develop a persuasive business case to secure the necessary support and resources. Build a dynamic core team, establish a precise target timeline, and foster a stimulating environment that encourages collaboration and innovation. Learn effective strategies to overcome barriers and implement an efficient control system to track progress and sustain achievements, while paving the way for performance breakthroughs and a culture of continuous improvement. Upon completion of this inaugural training, you will emerge with a clear understanding of the critical role a charter plays in program success. Armed with the tools and techniques acquired during the workshop, you will confidently create and present a well-crafted program charter to key stakeholders, ensuring alignment and support from the start. By establishing a solid foundation, the program is better equipped to avoid potential pitfalls, mitigate risks, and maintain focus on delivering successful outcomes. Ultimately, the training empowers participants like you to become more effective leaders who can drive initiatives forward, foster collaboration, and inspire teams to achieve extraordinary results.

- Part 1 Month 2 Strategic Alignment – Success in any project depends on aligning stakeholders’ expectations and goals. Stakeholders are individuals or groups that have an interest in the success of the project, such as customers, employees, shareholders, suppliers, and others. It is essential to understand their needs and align them to ensure the project’s success. However, if their needs are not aligned, the project is likely to fail. In this training module, you will learn how to identify the people and organizations that are directly or indirectly affected by the project, have an interest, have the power to influence, or have the authority to make decisions about its direction or outcome. You will identify their needs, which may be tangible items like products or profits or intangible items like trust, respect, and recognition. Clearly understanding the voice of the customer (VOC), voice of the business, (VOB), and voice of the employees (VOE) allows you to establish shared goals. You will align them with the overall strategy, communicate the strategy to key stakeholders, monitor progress and adjust the strategy as needed. Doing so encourages collaboration between different teams so that everyone is working toward the same goals. This strategic alignment ensures that the mission, objectives, and strategies are not conflicting with each other. It helps to ensure that the everyone is working towards the same objectives and resources are being used in the most effective way. Upon completion of this training, you will have the foundation for success by aligning stakeholders to support the project’s mission. You will have the tools and mandates necessary to move the project forward, addressing concerns and questions from individuals critical to success. By applying the techniques learned in this module, you will be able to align stakeholders, understand their needs, and develop strategies to meet them. This will improve communication, promote teamwork, and ensure project success.

- Part 1 Month 3 Problem Statement – Defining the problem to solve is crucial to achieving a successful outcome in any project. However, not everyone may be aware of the issue or recognize that there is even a problem, which can make it difficult to identify and address it. Additionally, some may argue that the problem is external and cannot be resolved internally. To overcome these obstacles and achieve the defined goal, an effective problem statement must be created. In this training module, you will learn how to create a concise and clear problem statement that provides focus, direction, and alignment for all stakeholders involved in the project. This statement includes the problem’s context, why it needs to be addressed, specific objectives, the approach to solving it, the impact of the solution on stakeholders, and how to evaluate success. The process begins with identifying the success metric, a quantifiable measure of progress towards the desired outcome. It is essential to select the right key performance indicator (KPI) for the project based on stakeholders’ needs and expectations. This can reveal potential conflicts that must be resolved to solidify the problem statement. Once the success metric is defined and aligned, you will establish the baseline and the performance gap. The baseline is the reference point at the start of the project to measure progress against, while the performance gap is the difference between the baseline and the expected result. Upon completion of this training, you will have identified the gap between the current state and the desired state, providing direction for solution development in the upcoming modules. You will have a clear understanding of which single problem needs to be solved, why, and how to measure success. The problem statement will also serve as a guide to ensure that all stakeholders remain focused on the same goal.

- Part 1 Month 4 Causal Analysis – Identifying the root cause of a problem is essential for effective problem-solving, yet stakeholders often struggle to comprehend the underlying reasons for an issue or have conflicting views on how to address it. Nonetheless, in science and business, it is commonly acknowledged that there is a cause for everything that occurs. By pinpointing the root cause of a problem, we can systematically address it and leverage opportunities for improvement. In this training module, you will learn how to identify the relationships between various variables in the system under investigation. By adopting a comprehensive approach to problem-solving, you will identify the underlying causes of problems, which is a prerequisite for developing effective solutions. Mapping the causal relationships between conditions, actions, and effects is one of the key tools for identifying root causes. This process facilitates understanding why certain outcomes occur and how different factors influence them. Creating a logic-tree that traces back from the symptoms to the root cause of the problem will provide insights into developing strategies for improving performance and preventing future issues. Causal analysis is a critical tool for decision-making as it allows the analysis of both qualitative and quantitative data. Understanding the relationships between different variables in the operating system provides a more holistic understanding of the problem, enabling informed decisions about how to address it. Upon completion of this training, you will have a firm grasp of the direct causes, contributing causes, and root causes of the problem. With this knowledge, you can develop effective solutions that eliminate the root causes of defects, deviations, delays, and disconnects. Ultimately, this leads to improved products and services that are delivered efficiently, resulting in higher customer satisfaction and improved business performance. The ability to identify root causes is a valuable skill for all stakeholders, enabling them to solve problems effectively and capitalize on opportunities for improvement.

- Part 1 Month 5 Solution Development – Despite identifying the root causes of the problem, finding a suitable solution remains elusive. To overcome this challenge, it is essential to prioritize appropriate countermeasures while considering operational and business constraints. Critical factors such as time, costs, people resources, and implementation difficulty must be evaluated to develop practical solutions for each identified cause. Focus must be on solutions that offer the greatest value and effectiveness for all stakeholders. Assessing the probability of success, risk of unintended consequences, stability of the solution over time, and feasibility of implementation based on practical considerations such as timeline, costs, and return on investment is essential to track progress and create impact. In this training module, you will learn how to overcome critical issues, how to identify and prioritize appropriate countermeasures while taking into consideration operational and business constraints. You will also learn to develop practical solutions for each identified cause, assessing the probability of success, risk of unintended consequences, and feasibility of implementation. Additionally, you will develop lead indicators at the operational level to track progress and lag indicators to measure impact. Monitoring lagging indicators at the financial level will help you gauge the effectiveness of your solutions and make any necessary adjustments. Upon completion of this training, you will have a solid solution plan that effectively eliminates the problem or significantly reduces the performance gap. This solution plan is fully actionable and can be executed by the implementation team, addressing the identified barriers effectively. It meets the goals and objectives of all stakeholders while ensuring safety and soundness without causing any harm or other negative consequences. The solution plan is comprehensive, leaving no room for excuses or escapes, and is ready for implementation. To ensure accountability, success measures are firmly integrated into the project scorecard.

- Part 1 Month 6 Pilot Study – To address performance gaps, numerous solution concepts have been developed. However, the effectiveness of these solutions has not been tested in real-life scenarios, leaving doubts about whether they would work under actual operating conditions. Therefore, the aim of this module is to address potential weaknesses of these solution concepts by testing them before implementing them on a larger scale. In this training module, you will learn how to perform a pilot study that tests the feasibility and effectiveness of potential solutions on a smaller scale in a controlled environment. A pilot study involves a limited sample size and resources, with the goal of identifying potential issues that may arise during a full-scale rollout. The process includes selecting a representative group of people and equipment, designing the study, developing a plan for the pilot, and defining the methods and materials to be used. The data collected is then analyzed to draw conclusions from the pilot study. If necessary, the solution concept is adjusted based on the results, and the study is repeated. Upon completion of this training, you will have validated the solution concept at a pilot-scale in a controlled environment and tested its effectiveness under actual operating conditions by carefully introducing constraints and variability. Through several iterations, the solution will be optimized until it is fully qualified, ensuring its successful implementation in the actual operating environment. By learning how to test the feasibility and effectiveness of solutions before implementing them on a larger scale, you will save time and resources, while also mitigating risks.

- Part 1 Month 7 Solution Roadmap – A well-defined plan is a crucial component of successful change management, strategy deployment, and project execution. Merely having a clear destination and committed crew is not enough to implement a solution. To navigate unfamiliar terrain, overcome obstacles, and accomplish the mission, a detailed roadmap is required. In this training module, you will learn how to develop a master plan that outlines the goal, milestones, success measures, and the most effective path to achieve the desired outcome. This roadmap is an essential communication tool that helps articulate what needs to change, why it needs to change, and the order in which changes should be made. It aligns the organization’s functions and activities vertically and horizontally with its project objectives. The roadmap specifies tasks, deliverables, timelines, responsibilities, and measures. Without such a solid plan, there will be false starts and constant course corrections, making it challenging to achieve real progress. Upon completion of this training, you will have a detailed implementation roadmap that makes the vision actionable and tangible. It considers the organization holistically, ensuring that all areas of change are well understood and adequately covered. Capability-based planning helps team members understand existing capabilities, the changes required to achieve the objective, and their priority. The resulting roadmap not only outlines how goals will be achieved, but it also specifies who is responsible, when resources are required, and for how long. It includes specific milestones and deliverables, making progress measurable and allowing for early identification of problems and corrections to keep the project on track.

- Part 1 Month 8 Capability Building – The introduction of new technologies or methods usually requires people to acquire new skills and capabilities. Without these essential abilities, anxiety and fear can take hold, leading to paralysis and an inability to adapt. To effectively manage change, it is important to identify which skills and capabilities are critical, which ones are already present, and which need to be developed. Moreover, motivating people to learn these new skills is key to project success and sustainability. In this training module, you will learn how to identify skill gaps and develop training plans to close them. The objective is to equip team members with the cognitive, socio-emotional, and technical skills required to implement the change and perform in the new way. Training plans need to address the mindset barrier of “I don’t know how” so that those involved in the transition can successfully think and work in the new way. This involves developing cognitive skills to understand complex ideas, perform advanced data analysis, solve complex problems, design and control technology. Additionally, socio-emotional skills are required to navigate interpersonal and social situations effectively, including leadership, teamwork, self-control, and grit. Technical skills, knowledge, expertise, and interactions must be considered to perform required tasks, including mastery of required materials, tools, and technologies. Along with developing training plans, it is important to identify motivators and create incentives for individuals to learn these skills. People are primarily motivated by two forces – gaining pleasure and avoiding pain. Therefore, individuals must perceive and receive benefits from the change to be willing to engage and learn new skills. If they do not see the value in the change, they are likely to resist implementing new processes. Upon completion of this training, you will have identified the skills and capabilities required from team members to perform effectively in the new structure and system. Skill matrices and effective training plans will have been developed and deployed, and incentives created to keep individuals motivated during the upskilling process until qualification is achieved. These steps are crucial preconditions for successfully execution of the roadmap.

- Part 1 Month 9 Solution Implementation – Implementing the new solution can involve introducing a new technology, restructuring an organization, streamlining workflows, or changing how people work. When the concept is already proven, a detailed plan is in place and people are trained to execute this plan, then it is crucial to ensure effective execution in an agile way to achieve success at full scope and scale. In this training module, you will learn how to implement a solution effectively, establish transparency and communicate clearly to ensure that all stakeholders are aware of the tasks, timeline, and any changes. Assigning clear roles and responsibilities helps ensure that everyone involved understands what is expected of them. Monitoring progress against the plan is necessary to identify any issues or roadblocks and make necessary adjustments to stay on track. You will also ensure access to necessary resources, such as equipment, software, and personnel, which is essential to successful implementation. Additionally, you will celebrate successes and encourage the team to learn from failures. This approach helps to keep the team motivated and focused on the goal while learning from setbacks. Establishing feedback loops allows for continuous improvement, gathering feedback from stakeholders and end-users helps to identify areas for change and ensure the implementation is meeting its intended purpose. Upon completion of this training, you will have developed the skills and capabilities for successful project execution. You will be capable to effectively execute the roadmap and realize desired outcomes. Communication, role clarity, resource availability, progress monitoring, celebration of successes, learning from failures, and positive feedback loops are essential for successful implementation. By following these key steps, you will guide the target organization to execute the solution effectively and achieve the intended outcomes.

- Part 1 Month 10 Solution Standard – After successfully implementing the solution, it is crucial to ensure that it remains effective over time. This is where standardization comes in. Standardization involves creating a consistent set of guidelines and procedures to embed the new structure, method, or system in the organization. Without standardization, there is a high risk that processes will deteriorate, variability will increase, performance will decline, and customer satisfaction over time. Therefore, standardization is essential to achieve sustainable success. In this training module, you will learn how to standardize the new way of working. You will follow a structured approach to identify the key areas where variability is high, and standardization is required to mitigate risk. This involves identifying the steps and workflows that are essential to achieve the desired outcomes. Once you have identified the areas that need standardization, you will learn how to develop standard procedures and instructions that are simple, clear, and concise. These instructions will provide guidance on how to perform the task, by whom, when, and how, including the tools, equipment, materials, and authority required. You will also learn how to embed these new procedures into existing structures and how to incorporate them into the regular review cycle to ensure they remain current and relevant. Upon completion of this training, you will have standardized and embedded the solution in the target organization. This standardization will result in improved quality, reduced variability, improved communication, and increased efficiency through this new structure, system, or procedure. Standardization lays the foundation for continuous improvement, making it easier to identify areas for improvement and make changes to the process. By achieving greater levels of consistency and efficiency, you will have improved customer satisfaction and overall performance levels. Standardization ensures that the output of the new process remains consistent, regardless of who performs the task or where it is performed. This consistency is important in achieving and maintaining high levels of customer satisfaction, leading to increased loyalty and growth.

- Part 1 Month 11 Impact Assessment – During and especially after implementing the solution, it is essential to assess its impact to determine whether it is delivering the intended benefits. Project impact assessment involves evaluating the effect of the project on the organization, stakeholders, and the environment. It helps to identify the strengths and weaknesses of the project and enables the team to make necessary adjustments to ensure that the desired outcome is achieved. In this training module, you will learn how to assess progress and impact on the operational and financial level. This process starts by analyzing key indicators from the scorecard, measuring the performance of the project during the deployment phase. These are quantifiable measures that evaluate the success of the project and are used to determine whether its objectives have been achieved. You will learn to use lead indicators to identify potential risks post implementation and lag indicators to project benefits for the next accounting period. Both types of indicators are required to assess progress and impact of the project. For the business case, financial benefits are an important aspect to evaluate success. This involves assessing the financial costs and benefits of the project, including the return on investment (ROI) and net present value (NPV). The business case for the project must be evaluated to ensure that it is delivering the desired financial benefits, and that the investment in the project was justified. Upon completion of this training, you will have established an impact assessment framework, defined the criteria for measuring success, analyzed scorecard data, and projected the financial impact over the accounting period following implementation, which is typically 12 months. The project’s business case will be updated to reflect implemented results and also expected benefits for the next accounting period.

- Part 1 Month 12 Learning Leverage – After successfully completing the project, it may be tempting to move on to the next task without looking back. However, this approach is inefficient because valuable lessons learned during the project could be applied to solve future challenges or problems more effectively. This is why it is essential to practice Yokoten, a Japanese term for “horizontal deployment” or “sharing”. It involves extracting and spreading best practices, knowledge, and ideas from the project across different areas of an organization to systematically drive continuous improvement. In this training module, you will learn how to practice Yokoten by identifying the key success factors of the project and documenting them, which includes the solutions implemented, challenges faced and instructions on how to overcome them. This document will then be used to educate people who will be implementing the same process in a new area. It will not only focus on technical aspects but also encourage collaboration and sharing of ideas among team members. Once the process is scheduled for implementation in a new area, you will define ways to monitor and measure its effectiveness to ensure continuous improvement. Upon completion of this training, you will have enabled your organization to reduce duplication of effort, improve quality and consistency, and create a culture of continuous improvement. By sharing best practices, teams learn from each other, improve efficiency, and achieve greater success together. The organization leverages learning by increasing scope and scale, identifying areas that could benefit from applying the lessons to a new project, establishing a new improvement or innovation team, documenting and sharing successful ideas from the current project, providing adequate training, and monitoring the effectiveness of new processes. By doing so, organizations can achieve improved efficiency and ultimately drive greater success.

Operational Excellence – Part 2 – Year 2 – Tactical

- Part 2 Month 1 Process House – Weather we realize it or not, everything we do is a process, and we all play part of many processes. The process house represents a holistic approach aimed at identifying core processes, support processes, and critical interfaces within an organization to optimize and streamline these processes to deliver maximum value to customers while enhancing efficiency and productivity. Failing to understand how processes interact leads to delays, breakdowns, inefficiencies, stonewalling, and unhappy customers. Take, for example, a manufacturing company that fails to define its processes and interfaces. Such a company is likely to face challenges in managing its supply chain efficiently, leading to delays in sourcing materials, poorly organized warehousing, and increased logistics costs. Additionally, there might be a lack of collaboration between departments, leading to a disconnect between engineering, research, and development practices, hindering innovation and improvement in their products. Customer-centric strategies may be undermined, causing reduced customer loyalty and negatively impacting sales and marketing efforts. In this workshop, you will learn how to identify core processes, support processes, and critical interfaces within your organization. You will explore methods to optimize value streams and enhance supply chain management, product lifecycle management, operations, customer relationship management, human resources, finance and controlling, information technology, quality management, process interface alignment, performance metrics monitoring, continuous improvement practices, and cross-functional collaboration. Upon completion of this training, you will be equipped with the knowledge and tools to identify and optimize core processes, enhance support processes, and align critical interfaces, leading to improved collaboration and smooth information flow.

- Part 2 Month 2 Target Conditions – They are specific future states that organizations aim to achieve through problem-solving and continuous improvement efforts. Unlike common goal setting, target conditions focus on critical processes and interfaces, providing a clear and concise definition of the desired state to be achieved, while driving effective problem-solving by providing a tangible destination for improvement efforts. Without defining these target states, the lack of clarity leads to ambiguous goals, making it challenging to measure progress accurately, leading to misalignment among team members and stakeholders, wasted time and resources, while struggling to prioritize improvement efforts, hindering the success of their initiatives. In this workshop, you will learn about the importance of clear and concise definition, enabling you to communicate target conditions effectively to teams and stakeholders. You will also gain insight into visualizing and comparing the target condition with the current state and desired future state, enhancing your understanding of the improvement journey, while considering resources, constraints, and stakeholders’ expectations. Upon completion of this training, you will have acquired the skills and knowledge to define clear and measurable target conditions. You will be adept at communicating the importance of such conditions and leveraging effective communication techniques to engage your teams and stakeholders. By integrating data-driven analysis into your decision-making processes, you will be able to assess the feasibility of your target conditions and mitigate potential risks. You will be equipped with problem-solving tools and methodologies, fostering a sense of ownership, urgency, and motivation among team members. Organizations, in turn, will benefit from increased efficiency, improved processes, and a culture of continuous improvement, ultimately driving greater success and achieving their strategic objectives.

- Part 2 Month 3 Digital Twins – They are virtual models to simulate real-world systems, enabling us to optimize processes, test improvement concepts, and make data-driven decisions. They will revolutionize our reality. Without such model, we miss out on a transformative tool that can significantly enhance our operational efficiency. For example, consider a manufacturing facility with a virtual model that mirrors the actual production line, allowing the team to simulate various scenarios and evaluate potential changes before implementing them in the real operational environment. This approach helps in identifying bottlenecks, optimizing resource allocation, and refining improvement concepts, leading to reduced downtime, increased throughput, and overall enhanced performance. In the workshop, you will gain comprehensive insights about digital twinning, starting with knowledge sharing to educate stakeholders about the concept’s significance. You will learn how to conduct a value identification assessment to recognize the specific benefits that a digital twin can bring to our operations. Additionally, the workshop will delve into data gathering, validation processes, and software evaluation, equipping you to develop a reliable and accurate twin. Integration planning will ensure a seamless merge with existing systems and processes, facilitating smooth data flow and interoperability. To address potential challenges, the workshop will include risk assessment and case study analysis, providing practical understanding and best practices for digital twinning. You will also learn how to leverage the digital twin for simulation modeling, defining performance metrics, identifying bottlenecks, and determining optimal update frequencies and detail levels. Upon completion of this training, you will possess the expertise to develop and maintain a digital model, enabling you to drive continuous improvement efforts within our operations.

- Part 2 Month 4 Lean Application – Lean is key to business survival, aimed at streamlining and standardizing processes to achieve complete, accurate, and timely output, by eliminating wastes, such as slack, excess, and defects. Lean, Agile, Six Sigma – so many approaches – what’s the difference? Lean focuses on streamlining and standardizing processes to eliminate wastes, while Agile emphasizes iterative and adaptive development, and Six Sigma aims at reducing defects and process variations through data-driven approaches. Without driving Lean, organizations experience inefficiency, increased costs, reduced customer satisfaction, and missed deadlines. This might not be a problem if you are operating as a monopoly. But most companies must be efficient to compete. To illustrate, let’s consider a manufacturing company that decides to apply Lean to production. Through careful analysis and process mapping, they identify bottlenecks, excessive inventory, and unnecessary transportation steps. By implementing flow, balancing workloads, and introducing pull systems, the company optimizes the process, resulting in reduced lead times, improved productivity, and better utilization of resources. In this workshop, participants will learn practical approaches to implementing Lean within their processes. Starting with identifying the target process, attendees will gain insights into understanding customer demand, creating detailed process maps, and conducting waste analysis. The workshop will focus on redesigning processes to establish smooth flow, synchronizing work with actual demand or planned schedule, and implementing pull systems and leveling procedures to ensure efficient operations. Creating standard work instructions, providing employee training, and utilizing visual management techniques foster a culture of continuous improvement. Upon completion of this training, participants will possess the knowledge and tools to optimize processes, leading to significantly reduced waste, increased productivity, and enhanced customer satisfaction.

- Part 2 Month 5 Six Sigma – That’s 99.99966% perfection or 3.4 problems in one million transactions. Six Sigma encompasses more than just quality levels, it’s about boosting capability for consistent, reliable, and efficient output, while reducing defects and enhancing overall performance. Neglecting Six Sigma principles often leads to uncontrolled variability, increased defect and error rates, operational inefficiencies, dissatisfied customers, and reduced competitiveness. For example, a company that ignores process variability may face quality issues, resulting in defects and inconsistencies, leading to customer complaints and loss of trust, ultimately affecting sales and revenue. The absence of data-driven decision-making and standardization further hampers the identification and resolution of underlying process issues. In this workshop, you will learn basic tools and methodologies to practically apply Six Sigma in your area, use SIPOC (Suppliers, Inputs, Process, Outputs, Customers), a high-level process mapping tool to provide an overview of a process and its key elements. You’ll further explore data analysis techniques to identify patterns affecting process capability and use process mapping to detect bottlenecks and improvement opportunities. You’ll employ Statistical Process Control (SPC) techniques for process monitoring and deviation detection. The workshop will also focus on skill development through problem-solving and statistical analysis training, empowering you and your team to address challenges effectively. By promoting cross-functional collaboration and integrating customer feedback, you’ll align the process with customer needs, enhancing overall satisfaction. Identifying automation opportunities and benchmarking against industry best practices further optimize process capability. Upon completion of this training, you will have the expertise to apply Six Sigma principles in your area for reliable and consistent output. Improved data analysis skills will lead to better decision-making, reducing defects and increasing efficiency. Continuous monitoring and review will sustain and build on improvements, benefiting your organization with enhanced customer satisfaction, competitiveness, and overall performance.

- Part 2 Month 6 Agile Application – Agile has revolutionized project management, leaving traditional methods behind. It aims to nurture an adaptive mindset, emphasizing collaboration and continuous learning. This fosters effective responses to changing priorities, customer feedback, and market demands, leading to increased efficiency and productivity. Without an agile mindset, teams struggle in dynamic work environments, causing rigid and inefficient processes. The absence of iterative and adaptive planning leads to projects exceeding schedules and budgets, with little room for adjustments. Lack of cross-functional teams and customer involvement results in siloed work and poor understanding of customer needs, affecting product quality. This workshop covers crucial aspects of Agile in OpEx. Participants will grasp the Agile mindset, stressing adaptability, collaboration, and continuous improvement. Topics include iterative planning, adaptive planning, and the significance of cross-functional teams in boosting efficiency. Involving customers and stakeholders throughout the process fosters transparency and product alignment. Additionally, the workshop implements Agile metrics for data-driven decisions on team performance and process efficiency. Participants will understand the value of daily stand-up meetings, sprint retrospectives, user stories, Kanban boards, timeboxing, feedback loops, and visual management, fostering communication and teamwork. After this training, participants will hold a comprehensive understanding of Agile principles tailored to OpEx. They will be equipped to instill an agile mindset, promoting adaptability and collaboration in their teams and organizations. The application of Agile methodologies will lead to increased productivity, better process efficiency, and a customer-centric approach, benefiting individuals and the organization as a whole. Agile is the way forward, leaving behind outdated traditional methods in project management.

- Part 2 Month 7 Portfolio Optimization – Businesses that streamlined their offerings experienced a 15% increase in profitability. Portfolio optimization involves strategically streamlining a company’s product and service offerings to maximize effectiveness. This process capitalizes on high-performing elements while eliminating low-performing ones, preventing reduced profitability, inefficient resource allocation, missed market opportunities, and loss of competitiveness. Imagine a fictional consumer electronics company with a wide range of products and services in its portfolio. Some are highly profitable and in demand, while others have dwindling sales and little customer value. Without portfolio optimization, the company might continue investing in less profitable products, reducing overall profitability. Additionally, without customer segmentation and market trend analysis, offerings may not align with changing consumer preferences, leading to potential market share loss to more adaptive competitors. This workshop provides a practical approach to portfolio optimization, covering key elements such as portfolio analysis, customer segmentation, market trend analysis, risk-return assessment, and product-service rationalization. Upon completion, participants will understand portfolio optimization’s vital role in operational excellence. They will gain practical tools to streamline their organization’s offerings, align with customer needs and market trends, and enhance profitability and competitiveness. The benefits extend to the entire team or organization, enabling informed decisions, efficient resource allocation, seizing market opportunities, and adapting proactively to changing dynamics for sustained success and growth.

- Part 2 Month 8 Workflow Digitalization – “Go digital or go obsolete” has never been more relevant. Workflow digitalization is crucial for modern businesses aiming to enhance operational performance through technology. It involves optimizing, automating, and streamlining processes to create an efficient and transparent workflow ecosystem, driving productivity and informed decision-making. Neglecting digitalization comes with severe consequences, including manual errors, slow processes, lack of real-time insights, decreased collaboration, and compromised data security. This impacts overall productivity and competitiveness. For instance, a manufacturing company relying on paper-based supply chain management faces delays in order processing, inventory tracking issues, and an inability to adapt to market demands, leading to bottlenecks and customer dissatisfaction. To address these challenges, a workshop offers practical tools and methodologies. Data analytics extracts meaningful insights, enabling data-driven decision-making and process optimization. Robotic automation delegates repetitive tasks to software robots, freeing human resources for strategic tasks. Cloud integration facilitates seamless collaboration and knowledge-sharing among teams. Workflow mapping identifies inefficiencies, while real-time monitoring tracks progress and performance metrics transparently. Digital collaboration tools foster communication and productivity, and gamification elements motivate employees to drive engagement. Implementing a digital feedback loop encourages continuous improvement and innovation. Virtual collaboration spaces cater to remote teams, ensuring efficient teamwork despite geographical barriers. In conclusion, embracing workflow digitalization empowers businesses to stay agile, competitive, and prepared for the future. By leveraging technology to its fullest potential, organizations can achieve sustained performance gains and thrive in the dynamic business landscape.

- Part 2 Month 9 Digital Standards – They are encompassing digitized Standard Operating Procedures (SOP) and Standard Work Instructions (SWI), are crucial for achieving process excellence, ensuring consistency, quality, and efficiency in task execution. For instance, in the medical field, the implementation of video procedures has revolutionized the way surgeons transfer their knowledge and experiences to improve the success rate of medical treatments. By digitizing surgical techniques and creating interactive “how-to” video instructions, experienced surgeons can share their expertise with their peers and aspiring medical professionals. These videos offer a detailed and visual understanding of complex procedures, allowing for better comprehension and learning. Younger surgeons can access these video instructions on their digital devices, review them repeatedly, and learn at their own pace. The accessibility and repeatability of video instructions contribute to skill development and competency enhancement, ultimately leading to improved surgical outcomes and patient care. Additionally, video procedures enable surgical teams to collaborate more effectively during critical procedures, ensuring that everyone is aligned with the best practices and standardized processes. This sharing of knowledge and experiences through digital means not only enhances the success rate of medical treatments but also promotes a culture of continuous learning and improvement within the medical community. In the workshop, participants will learn how to create e-instructions, develop user-friendly electronic procedures, implement version control, integrate performance metrics, and encourage cross-functional collaboration, among other topics. They will also gain insights into how digital standards can transform knowledge sharing and skill development, particularly in specialized fields like science, engineering, and management. Upon completion of this training, participants will have the knowledge and tools to enhance user experience, improve process consistency, increase efficiency, and achieve process excellence. The organization will benefit from standardized and updated procedures, reduced errors, improved productivity, and a more agile workflow, ultimately leading to increased overall performance. Moreover, in the medical field, the adoption of digital standards and video procedures will contribute to better outcomes at greater consistency and safety.

- Part 2 Month 10 Target Organization – Companies with well-structured target organizations see up to 30% higher employee engagement and productivity. The key lies in developing a robust framework that ensures capable, empowered, and accountable individuals within the organization, aligned with its vision and goals. A target organization fosters a culture of leadership, empowering employees to take charge and contribute effectively. Without such a structure, inefficiencies, misaligned efforts, and reduced employee morale can arise, hindering long-term success. For example, a financial institution seeking service efficiency and customer satisfaction may suffer from unclear roles and a lack of accountability, resulting in reduced employee productivity and hindrance to growth. In this workshop, participants will learn essential components of a target organization. Leadership development will be emphasized, nurturing capable leaders at all levels. An empowerment framework will be explored to delegate authority and decision-making, fostering ownership and empowerment. Ongoing skill enhancement through training and development will bolster individual capabilities. An accountability matrix will clarify roles and responsibilities, instilling a culture of responsibility. Performance metrics will measure individual contributions, promoting continuous improvement. Talent acquisition strategies will attract skilled individuals aligned with the organization’s vision. Mentorship programs and succession plans will foster knowledge transfer and groom future leaders. Completion of this training equips participants to develop and implement a target organization for OpEx objectives. Capable leaders, empowered individuals, and accountability will be cultivated, benefiting the entire organization. A well-structured target organization will lead to enhanced productivity, streamlined operations, and sustained competitive advantage, enabling success amidst evolving business challenges and opportunities.

- Part 2 Month 11 Tactical Scorecard – They contribute significantly to top-performing companies’ success, accounting for 45% of their achievements. These scorecards play a crucial role in operational excellence by fostering transparency and alignment within organizations. They establish a comprehensive framework of leading metrics and tactics, enabling progress tracking and goal alignment. Without an efficient tactical scorecard, companies face challenges in identifying constraints and focusing on key performance drivers. For instance, a service-based company aiming to improve customer satisfaction may miss out on crucial leading metrics that directly impact customer experience, leading to missed opportunities for improvement. This lack of focus results in stagnant customer satisfaction levels and an inability to address root causes of complaints, ultimately impacting long-term success and customer retention. To address these issues, a workshop offers essential tactics for building an effective tactical scorecard that prioritizes leading metrics. Clear, measurable performance indicators are emphasized to influence operational success positively. Tactics like stakeholder mapping, data integration, and feedback loops are explored to ensure accurate measurement and goal-oriented decision-making. The workshop also covers continuous improvement processes, including regular performance reviews, root cause analysis, and benchmarking against industry best practices. Participants learn to implement real-time reporting mechanisms to swiftly make course corrections when leading metrics deviate from expected outcomes. Upon completing the training, participants gain a comprehensive understanding of constructing a tactical scorecard. They become equipped to drive significant operational improvements, achieve strategic objectives, and proactively respond to challenges. The organization benefits from insights to reengineer products and processes for better performance and a stronger market position. With a well-executed tactical scorecard, companies can navigate the dynamic business landscape with confidence, securing sustained success.

- Part 2 Month 12 Execution Engine – In essence, is a turbocharged management system to achieve automatic excellence. It integrates various strategies, including establishing a learning loop for continuous feedback, designing and integrating performance metrics aligned with strategic objectives, cultivating a culture of experimentation and iteration, and implementing mechanisms to promote knowledge flow and collaboration across departments. Customer focus, stakeholder engagement, resilient design, and data-driven decision-making are also integral components. Missing the execution engine means reinventing the wheel every time. For example, imagine a manufacturing company that lacks an execution engine. They struggle with outdated processes, low employee engagement, and limited collaboration between departments. They receive customer complaints about product quality and slow delivery times, leading to decreased customer satisfaction and ultimately a decline in sales. Without a systematic approach to continuous improvement and data-driven decision-making, the company fails to address these issues effectively, resulting in a significant loss of market share to competitors. In this workshop, you will learn how to build and implement an execution engine to enhance performance. The workshop covers strategies such as learning loops, integrated performance metrics, a culture of experimentation and knowledge sharing, and customer-centric decision-making. You will also gain insights into resilient design, data-driven decision-making, and fostering an innovation ecosystem within your area of responsibility. Upon completion of this training, you will have the tools and knowledge to develop and implement a robust OpEx execution engine. The systematic approach to automatic excellence will result in increased customer satisfaction, higher employee engagement, and better overall performance – through a robust system.

Operational Excellence – Part 3 – Year 3 – Strategic